Catalog excerpts

control focused - technology driven

Open the catalog to page 1

Benefits/Features of SCX180 Improved efficiency means more work with less fuel • Designed to minimize pressure drops • High flow / low pressure drop capability in a compact package • Dual tank rails that connect in each section Increased productivity by improving vehicle controllability • Multi-function flow sharing, even when flow demand exceeds flow supply • Pressure compensation provides consistent flow rates, regardless of load pressure • Precise metering capabilities Simplified hydraulic system with features integrated into the main control valve • Manual, hydraulic pilot operated,...

Open the catalog to page 2

control focused - technology driven SCX180 Technical Description, Product Benefits & Features 5 Standard Spool Flow Rates 7 Standard Spool Pressure Drops (Inlet to Work Port) and Compensator Performance 8 Standard Spool Pressure Drops (Work Port to Outlet) 9 Inlet Selection Assembly Options 11-12 Spool Section Assembly Options 13-17 Outlet Selection Assembly Options 18-19 Relief Valves, End Mechanisms & Kits 20-25 Appendix 1 Open Center versus Closed Center 26 Appendix 2 Post-Compensated versus Pre-Compensated 27

Open the catalog to page 3

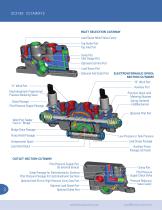

INLET SELECTION CUTAWAY Load Sense Relief Valve Cavity Top Outlet Port Top Inlet Port Sump Port Inlet Gauge Port Optional End Inlet Port Load Sense Port Optional End Outlet Port ELECTROHYDRAULIC SPOOL SECTION CUTAWAY “B” Work Port “A” Work Port Auxiliary Port Electrohydraulic Proportional Pressure Reducing Valve Precision Spool with Metering Notches Spring Centered EndMechanism Sump Passage Pilot Pressure Supply Passage Optioinal Pilot Port Work Port Feeder Core or “Bridge” Bridge Drain Passage Pump (Inlet) Passage Low Pressure or Tank Pressure Load Sense Passage Compensator Spool Load Hold...

Open the catalog to page 4

SPOOL CONTROL OPTIONS: Manual Control Hydraulically Pilot Operated Control Electrohydraulic Control Pneumatically Pilot Operated Control SIZE: Section Width SEALS: BUNA-N (standard) VITON (optional) STANDARD PORT SIZES (MAXIMUM): Inlet (P) Work Ports (A) and (B) High Pressure Carry Over (HPCO) Outlet (T) STANDARD INTERNAL LEAKAGE RATES: Rated Work Port Leakage (A or BxT) tested with 70 bar (1,015 psi) Separate Section Assemblies 2 3 ∆P at 43 ± 4 C (110° ± 10° F) and 28 – 35 mm /sec (135 – 165 SSU) 25 cm /min 1.5 in3/min kinematic viscosity Finished Valve Assemblies 16 cm3/min 1.0 in3/min...

Open the catalog to page 5

SCX180 is a closed-center, load-sensing, sectional control valve with post-pressure compensation that offers a wide range of control options and flexibility. SCX180 can be used with fixed displacement pumps or with pressure-compensated, load-sensing variable displacement pumps and can be configured with one to ten working sections. The load sense (LS) pressure in an SCX180 valve is generated by the compensator spool using the HUSCO patented IsoComp™ method to copy the LS signal using oil supplied by the pump instead of stealing oil from the function. Using pump oil to generate the LS signal...

Open the catalog to page 6

The SCX180 3-position spool is interchangeable between manual, pilot operated and electrohydraulically operated section assemblies. Each spool has a threaded hole on both ends, allowing any spool to be a left-handed or right-handed spool. Flow rates are based on a 15 bar (215 psi) pump to LS differential pressure. Each spool is designed for the same flow rates for both work ports. Spool Flow Rate Cylinder Spool Part Number Restricted Motor Spool Part Number Full Motor Spool Part Number MANUALLY OPERATED HYDRAULICALLY PILOT OPERATED ELECTROHYDRAULICALLY OPERATED

Open the catalog to page 7

WORK PORT FLOW VERSUS PUMP-LS DIFFERENTIAL PRESSURE Pump-LS Differential Pressure (psid) 145 320 Full Flow Spool Work Port Flow (gpm) Work Port Flow (lpm) Pump-LS Differential Pressure (bar) SCX180 STANDARD SPOOLS WORK PORT FLOWS VERSUS TRAVEL Full Flow Spool Notes: • Force values are based on standard 3-position manual spring end mechanism 61501 • Pilot pressure values are based on 61499 series of pilot operated end mechanisms • Current values are based on the 12 VDC, 20 bar proportional pressure reducing valve

Open the catalog to page 8

SCX180 STANDARD SPOOLS INLET TO WORK PORT PRESSURE DROP Work Port Flow (gpm) 0 Pressure Differential (psid) Work Port Flow (lpm) COMPENSATOR PERFORMANCE – WORK PORT FLOW VERSUS LOAD PRESSURE Load Pressure (psi) 0 Work Port Flow Rate (lpm) Work Port Flow Rate (gpm)

Open the catalog to page 9

INLET TO WORK PORT PRESSURE DROPS SCX180 FULL FLOW SPOOLS INLET TO WORK PORT PRESSURE DROP – PUMPING INTO INLET HOUSING SCX180 FULL FLOW SPOOLS INLET TO WORK PORT PRESSURE DROP – PUMPING INTO OUTLET HOUSING Pressure Differential (psid) WORK PORT TO OUTLET PRESSURE DROPS SCX180 FULL FLOW SPOOLS SCX180 FULL FLOW SPOOLS WORK PORT TO OUTLET PRESSURE DROP – FLOWING OUT OF INLET HOUSING WORK PORT TO OUTLET PRESSURE DROP – FLOWING OUT OF OUTLET HOUSING Pressure Differential (psid) Pressure Differential (psid)

Open the catalog to page 10

control focused - technology driven LOAD SENSE PORT INLET PORT STROKE LIMITER VALVE MOUNTING REQUIREMENTS MOUNTING ORIENTATION IS NOT RESTRICTED. MOUNTING SURFACE MUST BE FLAT AND RIGID AND VALVE MUST BE MOUNTED WITH ONLY 3 MOUNTING BOLTS TO AVOID VALVE ASSEMBLY DISTORTION AND SPOOL BIND. ELECTROHYDRAULIC PROPORTIONAL PRESSURE REDUCING VALVE SUPPLY SOLENOID PILOT SUPPLY PORT— SUMP PORT MOUNT HOLE LOAD SENSE RELIEF VALVE OUTLET PORT LOAD SENSE PORT MOUNTING FOOT SPOOL DETAIL

Open the catalog to page 11

LET SECTION ASSEMBLY OPTIOI SCX181-E INLET SECTION ASSEMBLIES Designed for use with variable displacement, pressure-compensated load-sensing pumps Inlets come standard with a load sense relief valve cavity machined for the 56903 load sense relief valve Inlets come standard with an inlet pressure relief valve cavity machined for 51650-2 relief valves or 52610 shut-off plugs See table below for port options LOAD SENSE RELIEF PORT INLET GAUGE PORT- INLET RELIEF PORT- Consult HUSCO Sales department for non-standard options

Open the catalog to page 12

INLET SECTION ASSEMBLY OPTIONS control focused - technology driven SCX181-C INLET SECTION ASSEMBLY (UNLOADER / BYPASS COMPENSATOR INLET) Designed for use with fixed UNLOADER INLET (BYPASS COMPENSATOR) PERFORMANCE displacement pumps Inlet Flow (gpm] bias spring to create pump-to-LS s Inlet comes standard with a load J; sense relief valve cavity machined for ^ the 56903 load sense relief valve i Inlet comes standard with an inlet t pressure relief valve cavity machined ^ for the 60360 series relief valve, 61056 relief ° valve or 61650 shut off plug j See table below for port options LOAD...

Open the catalog to page 13All Husco International catalogs and technical brochures

-

SCX300

1 Pages

-

VF1600e

1 Pages

-

VF1200

1 Pages

-

5000-valve

36 Pages

-

6000-valve

30 Pages

-

6400-valves

1 Pages

-

6600-series

2 Pages

-

7100-valve

15 Pages

-

9210-valve

6 Pages

-

9610-valve

1 Pages

-

PPCs and Joysticks

15 Pages

-

HUSCO Hitch with EZ Select

2 Pages

-

Hitch Control Valves

1 Pages

-

Header Control Valve

1 Pages

-

Suspension

1 Pages

-

HEC-808

2 Pages

-

HVC

1 Pages

-

EHPV

2 Pages

-

Hitch Control

1 Pages

-

5000

35 Pages

-

VF1200e

1 Pages

-

VF1000

1 Pages

-

SCX120

32 Pages