Catalog excerpts

SECTIONAL VALVl

Open the catalog to page 1

SECTIONAL CUTAWAY Inlet Port Outlet Port Auxiliary Valve Port Accepts 5060 Style Main Relief SECTION CUTAWAY Parallel Passage Load Check Work Port Feeder Core or Mechanism-Many Other Options Avail Auxiliary Port-See Pages 20-22 for Work Port Options O-Ring/Wiper Spool Seal Combination Precision Spool with Metering Notches Patented One O-Ring Seal Between Sections-an Industr Proven Leak-Free Design PARALLEL CIRCUIT SPOOL SECTION Beyond Port Beyond Port Auxiliary Valve Port used to Convert Valve for Power Beyond-See Page 18 UNIVERSAL OUTLET/ POWER BEYOND SECTION CUTAWAY

Open the catalog to page 2

The Model 5000 is a sectional body directional control valve line designed for hydraulic systems. A completed Model 5000 valve assembly is made from an assortment of valve component sections and options to provide the desired directional control valve circuit. This catalog fully illustrates the component features and options you need to specify, build and service a Model 5000 directional valve that precisely matches your • 3000 psi operating pressure rating (207 Bar). • Open center or closed center operation. • Hard chrome plated spools. • Load check in each section. • Single "low pressure"...

Open the catalog to page 3

PRESSURE DROP CURVES THROUGH NEUTRAL INLET TO WORK PORT WORK PORT WORK PORT TECHNICAL DATA (Method of verifying rated pressure containing envelope conforms to NFPA Recom- " Higher pressure applications consult Husco THROUGH NEUTRAL WORK PORT TO TANK WORK PORT WORK PORT Maximum number of spool sections (any We reserve the right to amend these specifications at any time without notice. The only warranty applicable is our standard written warranty. We make no other warranty, expressed or implied. Performance characteristics shown are typical of production units tested in the laboratory and are...

Open the catalog to page 5

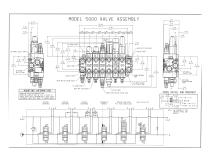

MODEL 5000 VALVE ASSEMBLY OUTLET PORT- MAIN RELIEF VALVE ASSY.- MOUNTING INFORMATION MOUNTING POSITION UNRESTRICTED. MOUNTING SURFACE MUST BE FLAT s RIGID TO AVOID VALVE STACK DEFORMATION 4 SPOOL BIND. RECOMMEND THREE BOLT MOUNT TO INSURE ABOVE. SHUT -OFF PLUG ASSY.- -PILOT PORT -WORK PORT RELIEF VALVE ASSY. SPOOL DETAIL AND MOVEMENT SPRING CENTERED AUTO KICK-OUT

Open the catalog to page 6

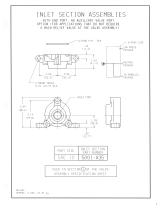

INLET SECTION ASSEMBLIES WITH END PORT, NO AUXILIARY VALVE PORT OPTION (FOR APPLICATIONS THAT DO NOT REQUIRE A MAIN RELIEF VALVE AT THE VALVE ASSEMBLY) INLET PORT ASSEMBLY SPECIFICATION SHEET

Open the catalog to page 7

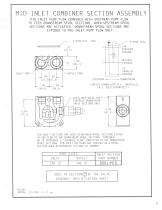

MID-INLET COMBINER SECTION ASSEMBLY MID-INLET PUMP FLOW COMBINES WITH UPSTREAM PUMP FLOW TO FEED DOWNSTREAM SPOOL SECTIONS. WHEN UPSTREAM SPOOL SECTIONS ARE ACTIVATED. DOWNSTREAM SPOOL SECTIONS ARE EXPOSED TO MID-INLET PUMP FLOW ONLY. INLET PORT OUTLET PORT O-RING SIDE CIRCUIT SHOWN WITH R.V. INSTALLED MID-INLET SECTIONS ARE USED IN-BETWEEN SPOOL SECTIONS EITHER TO ADD FLOW TO THE DOWNSTREAM SPOOL SECTIONS "COMBINER" OR TO INTRODUCE A "SEPARATE FLOW" CONDITION TO THE DOWNSTREAM SPOOL SECTIONS. MID-INLET SECTIONS ARE COUNTED AS A SPOOL SECTION WHEN DETERMINING TIE ROD KIT NUMBER. USED IN...

Open the catalog to page 8

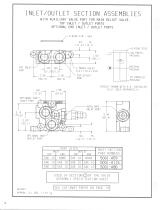

INLET/OUTLET SECTION ASSEMBLIES WITH AUXILIARY VALVE PORT FOR MAIN RELIEF VALVE. TOP INLET / OUTLET PORTS OPTIONAL END INLET / OUTLET PORTS —O-RING SIDE OUTLET PORT CIRCUIT SHOWN WITH R.V. INSTALLED VALVE PORT USED IN SECT I ON (T) OF THE VALVE ASSEMBLY SPECIFICATION SHEET LM-iruT SEE CUT-AWAY PHOTO ON PAGE 19

Open the catalog to page 9

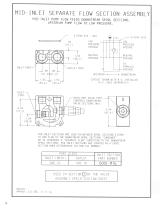

MID-INLET SEPARATE FLOW SECTION ASSEMBLY MID-INLET PUMP FLOW FEEDS DOWNSTREAM SPOOL SECTIONS. UPSTREAM PUMP FLOW TO LOW PRESSURE. INLET PORT- OUTLET PORT O-RING SIDE CIRCUIT SHOWN WITH R.V. INSTALLED MID-INLET SECTIONS ARE USED IN-BETWEEN SPOOL SECTIONS EITHER TO ADD FLOW TO THE DOWNSTREAM SPOOL SECTIONS "COMBINER" OR TO INTRODUCE A "SEPARATE FLOW" CONDITION TO THE DOWNSTREAM SPOOL SECTIONS. MID-INLET SECTIONS ARE COUNTED AS A SPOOL SECTION WHEN DETERMINING TIE ROD KIT NUMBER. USED IN SECTION(|)OF THE VALVE ASSEMBLY SPECIFICATION SHEET

Open the catalog to page 10

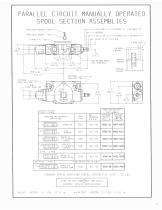

PARALLEL CIRCUIT MANUALLY UPERATED SPOOL SECTION ASSEMBLIES LOAD CHECK SPRING - 506.4 LOAD CHECK POPPET - 5011 O-RING SIDE SPOOL SECTION ASSY. PART NUMBERS (SINGLE ACTING) + ONLY ONE AUX. PORT ("A" SIDE) DETENTED FLOAT STANDARD SPRING CENTERING FORCES (SPRING P/N: 5014) ■ 37 LBS ASSEMBLY SPECIFICATION SHEET WEIGHT : APPROX. 5.1 LBS. 12.31 kg ** WEIGHT : APPROX. 5.4 LBS. 12.41 kg

Open the catalog to page 11

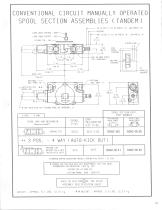

CONVENTIONAL CIRCUIT MANUALLY OPERATED SPOOL SECTION ASSEMBLIES (TANDEM) LOAD CHECK SPRING - 5064 LOAD CHECK POPPET - 501 O-RING SIDE ■-*■ SEE AUTO KICK-OUT FEATURE PAGE 28 (APPENDIX 1) SPOOL SECTION ASSY. PART NUMBERS VALVE PORTS VALVE PORTS STANDARD SPRING CENTERING FORCES (SPRING P/N: 5014) - 37 LBS. •*- REMOVE CAP FOR AUTO-KICK OUT ADJUSTMENTS. USE FLAT HEAD ASSEMBLY SPECIFICATION SHEET WEIGHT : APPROX. 5.1 LBS. 12.31 kg WEIGHT : APPROX. 5.8 LBS. 12.51 kg

Open the catalog to page 12

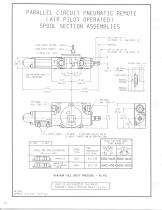

PARALLEL CIRCUIT PNEUMATIC REMOTE SPOOL SECTION ASSEMBLIES LOAD CHECK SPRING - 5064 LOAD CHECK POPPET - 501 2 PILOT PORTS - 1/8 NPTF - IF NO PORT RELIEF VALVE IS USED - PORTS CAN BE ROTATED 180' SPOOL SECTION ASSY PART NUMBERS VALVE PORTS MINIMUM FULL SHIFT PRESSURE ■ 90 PSI ASSEMBLY SPECIFICATION SHEET ( Pg 26)

Open the catalog to page 13

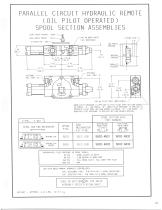

PARALLEL CIRCUIT HYDRAULIC REMOTE SPOOL SECTION ASSEMBLIES LOAD CHECK SPRING - 5064 LOAD CHECK POPPET - 501! O-RING SIDE SAE •£» PILOT PORT (BOTH ENDS) —' WHEN PILOT PRESSURE IS APPLIED TO THIS PILOT PORT SECTION SENSES Hl-PRESS. •A". LOW PRESS. -B\ WHEN PILOT PRESSURE IS APPLIED TO OPPOSITE PILOT PORT SECTION SENSES HI-PRESS. "B\ LOW PRESS. "A". WHEN NO PILOT PRESSURE IS APPLIED SECTION SENSES NEUTRAL. SPOOL SECTION ASSY. PART NUMBERS VALVE PORTS VALVE PORTS APPROXIMATE PILOT PRESSURE VS SPOOL TRAVEL: 20 PSI -- SPOOL STARTS TO SHIFT 80 PSI -- FLOW BEGINS AT WORK PORT 360 PSI -- FULL SPOOL...

Open the catalog to page 14

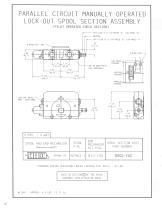

PARALLEL CIRCUIT MANUALLY OPERATED LOCK-OUT SPOOL SECTION ASSEMBLY (PILOT OPERATED CHECK SECTION) O-RING SIDE LOCK-OUT VALVE ASSY * BOTH ENDS STANDARD SPRING CENTERING FORCES (SPRING P/N: 5014) - 37 LBS. USED IN SECT 10N(2>0F THE VALVE ASSEMBLY SPECIFICATION SHEET

Open the catalog to page 15

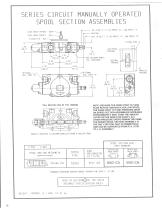

SERIES CIRCUIT MANUALLY OPERATED SPOOL SECTION ASSEMBLIES FULL SECTION VIEW OF P/N, 5002E3f> NOTE: BECAUSE THE WORK PORT TO TANK FLOW PATH IS THROUGH A HOLLOW SPOOL, THE WORK PORT TO TANK PRESSURE DROP ON SERIES SECTION ASSEMBLIES INCREASES APPROXIMATELY 300% OVER THE AMOUNT LISTED ON THE GRAPH ON PAGE 5. ALL OTHER PRESSURE DROPS REMAIN THE SAME. THE SERIES SPOOL SECTION ASSEMBLY IS THE ONLY SECTION THAT IS SYMMETRICAL SERIES CIRCUITRY IS ACCOMPLISHED BY USING A HOLLOW SPOOL STANDARD CENTERING SPRING FORCES (SPRING P/N: 5014) • 37 LBS. ASSEMBLY SPECIFICATION SHEET

Open the catalog to page 16All Husco International catalogs and technical brochures

-

SCX180

32 Pages

-

SCX300

1 Pages

-

VF1600e

1 Pages

-

VF1200

1 Pages

-

5000-valve

36 Pages

-

6000-valve

30 Pages

-

6400-valves

1 Pages

-

6600-series

2 Pages

-

7100-valve

15 Pages

-

9210-valve

6 Pages

-

9610-valve

1 Pages

-

PPCs and Joysticks

15 Pages

-

HUSCO Hitch with EZ Select

2 Pages

-

Hitch Control Valves

1 Pages

-

Header Control Valve

1 Pages

-

Suspension

1 Pages

-

HEC-808

2 Pages

-

HVC

1 Pages

-

EHPV

2 Pages

-

Hitch Control

1 Pages

-

VF1200e

1 Pages

-

VF1000

1 Pages

-

SCX120

32 Pages