Website:

Hurst

Website:

Hurst

Group: Nidec Corporation

Catalog excerpts

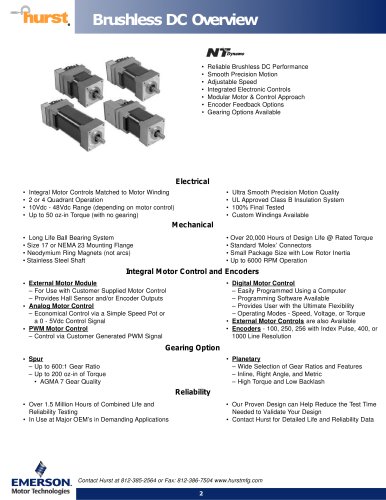

Reliable Brushless DC Performance?Smooth Precision Motion?Adjustable Speed?Integrated Electronic Controls?Modular Motor & Control Approach?Encoder Feedback Options?Gearing Options Available ?Integral Motor Controls Matched to Motor Winding?2 or 4 Quadrant Operation?10Vdc - 48Vdc Range (depending on motor control)?Up to 50 oz-in Torque (with no gearing)?Long Life Ball Bearing System? Size 17 or NEMA23 Mounting Flange? Neodymium Ring Magnets (not arcs)? Stainless Steel Shaft > ?Ultra Smooth Precision Motion Quality?ULApproved Class B Insulation System?100% Final Tested?Custom Windings Available? Over 20,000 Hours of Design Life @ Rated Torque? Standard ՑMolexConnectors? Small Package Size with Low Rotor Inertia? Up to 6000 RPM Operation ? > ҕ External Motor Module Digital Motor Control For Use with Customer Supplied Motor Control֖Provides Hall Sensor and/or Encoder Outputs Easily Programmed Using a Computer֖Programming Software AvailableProvides User with the Ultimate Flexibility֖Operating Modes - Speed, Voltage, or Torque? ? Analog Motor Control Economical Control via a Simple Speed Pot ora 0 - 5Vdc Control Signal External Motor Controls are also Available? ? PWM Motor Control Encoders - 100, 250, 256 with Index Pulse, 400, or1000 Line Resolution? ֖Control via Customer Generated PWM Signal > ? Spur Planetary Up to 600:1 Gear Ratio֖Up to 200 oz-in of Torque?AGMA7 Gear Quality?Over 1.5 Million Hours of Combined Life andReliabilityTesting?In Use at Major OEMs in Demanding Applications ҖWide Selection of Gear Ratios and FeaturesInline, Right Angle, and Metric֖HighTorque and Low Backlash?Our Proven Design can Help Reduce the TestTimeNeeded to Validate Your Design?Contact Hurst for Detailed Life and Reliability Data > Contact Hurst at 812-385-2564 or Fax: 812-386-7504 www.hurstmfg.com 2 size="-1">

Open the catalog to page 1

Note:? Performance data shown is typical. More detailed data is available from Hurst for each of the above ratings. Ambient operatingtemperature range: 0 - 40C.?The solid portion of the diagonal line is continuous duty and the dotted line represents momentary operation.?At 25аC ambient the max motor winding operating temperature rise is 65C with motor mounted to a 2.50" x 2.50" x 0.25" aluminum plate. Contact Hurst at 812-385-2564 or Fax: 812-386-7504 www.hurstmfg.com 4 >

Open the catalog to page 3

Size 17 NEMA 23 > Note: Above views are shown with Analog control. Connection Cabling ΕRefer to the Dynamo Model Number Chart for choosing the correct cableAll standard cables are 24Ք long Flying leads are supplied on customer end ՕCabling includes Control, Power, and Encoder cables Custom cables are available upon request > Contact Hurst at 812-385-2564 or Fax: 812-386-7504 www.hurstmfg.com 5 size="-1">

Open the catalog to page 4

External -The External Control Module (commutation board) simplifies the connection of an external motor drive to theDynamo motor by providing the user with a standard set of hall signals, numerous encoder options, and a high currentconnector for the motor phase windings. The module is compatible with external motor drives using a 10 to 48Vdc powersupply.The External Control Module provides a standard system for rotor position sensing required by most brushless motordrives. Three hall devices spaced 120 electrical degrees apart, sense a magnetic disk which is synchronized to the rotorof the...

Open the catalog to page 5

Contact Hurst at 812-385-2564 or Fax: 812-386-7504 www.hurstmfg.com 7 >

Open the catalog to page 6

Hurst will assist you in the selection of the best gearhead solution for your application.Some factors to consider in maximizing your application systems performance:Torque Multiplication Speed Reduction Inertia MatchingRadial Loading Axial Loading Noise Spur gearheads will suit most needs in relatively low-torque applications. However, spur configurations have higherbacklash and are usually less efficient than planetary types of similar construction. For constant velocity and unidirectionalapplications where backlash is less of a concern, spur gearheads are ideal. Planetary gearheads are...

Open the catalog to page 7

Note: Above views are shown with Analog control. Contact Hurst at 812-385-2564 or Fax: 812-386-7504 www.hurstmfg.com 9 >

Open the catalog to page 8

MM Series High Per for mance ?True Planetary Design?Integrated Design-Motor, Gearhead and Motor Control in One Compact Package-Eliminates Extra Parts -Improves Reliability and System Performance?Lowest Backlash DesignօLess than 10 Arc. Min.?Strong, Caged Roller Bearings?High Shaft Loading Capacity?High Efficiency Over 90%?HighTorque?Viton O-Ring Sealed at Each Joint?Sealed Ball Bearings?All Gears are Heat Treated?NEMAMounting Standards Size 17 NEMA 23 > Note: Above views are shown with Analog control. Contact Hurst at 812-385-2564 or Fax: 812-386-7504 www.hurstmfg.com 10 size="-1">

Open the catalog to page 9

Contact Hurst at 812-385-2564 or Fax: 812-386-7504 www.hurstmfg.com 11 >

Open the catalog to page 10

JB Series - Moderate Per for mance Inline Planetar y ?True planetary design?Low backlash design?Strong, caged roller bearings?Sealed ball bearings?All gears are heat treated?NEMAmounting standards SE Series - High Per for mance Metric Inline Planetar y ?Metric and NEMAmounting available?True planetary design?High radial and axial shaft loading capacity?Low start-up torque?High torque capability?Popular metric output shaft and front bracket design?Low backlash design EW Series - Pr ecision Right Angle Planetar y > Contact Hurst at 812-385-2564 or Fax: 812-386-7504 www.hurstmfg.com 12...

Open the catalog to page 11All Hurst catalogs and technical brochures

-

BRUSHLESS DC MOTOR FAMILY

7 Pages

-

HURST® 2008 Catalog

55 Pages