Catalog excerpts

development, production precision motors

Open the catalog to page 1

P;irt Ntimboi Snquoiico Contact Huisf at 612-385-2564 ut Fax: 812-386-7504 WWW.hurst-motors.com

Open the catalog to page 2

Advantages Disadvantages Dynamic braking RPOJ lirps Controller High efficiency Oomplox Drive Advantages Disadvantages Dyramic braking Demag at low, temp High efficiency Urush wpar Hybrid Stepper Analog Control External Control 50oz-in OMR pago 3 S Digital Control Spur Gear Planetary Gear Other Gear Direct (Jjrr^nl Linear Actuator Heavy Duly Hirjh Slip Normal Slip 150 oz-in A'Ali page 4 I ^> 200 oz-in PA/PB page 43 S> '00 oz-in OA/SO pace 43 Contact Hurst at 812-385-2564 or tax: 812-386-7504 www hurst-motors, com

Open the catalog to page 3

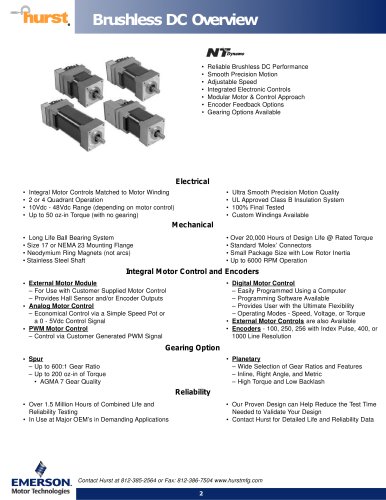

Reliable Brushless DC Performance Smooth Precision Motion Adjustable Speed Integrated Electronic Controls Modular Motor & Control Approach Encoder Feedback Options Gearing Options Available Integral Motor Controls Matched to Motor Winding 10Vdc- 48Vdc Range (depending on motor control) Up to 50 oz-in Torque (with no gearing) Long Life Ball Bearing System Size 17 or NEMA 23 Mounting Flange Neodymium Ring Magnets (not arcs) Stainless Steel Shaft Ultra Smooth Precision Motion Quality UL Approved Class B Insulation System Custom Windings Available Over 20,000 Hours of Design Life @ Rated Torque...

Open the catalog to page 4

Brushless DC Selection Guide Typical Applications Office Automation Medical Equipment Variable Speed Feeder Equipment Model Selection Guide (for gearmotors see page 8) To construct a motor part number substitute the appropriate digits for the x's as shown below. *use only w/ External Motor Speed Torque Speed Torque The RS232 Interface Kit and Software package is required to change the factory program settings on the Digital Motor Control or to operate the Dynamo motor using your computer's RS232 port. • Converter power supply • Converter interface cable • Programming software • Installation...

Open the catalog to page 5

Brushless DC Speed Torque Curves Torque (oz-in) Torque (oz-in) Torque (oz-in) Torque (oz-in) • Performance data shown is typical. More detailed data is available from Hurst for each of the above ratings. Ambient operating • The solid portion of the diagonal line is continuous duty and the dotted line represents momentary operation. •At 25°C ambient the max motor winding operating temperature rise is 65°C with motor mounted to a 2.50" x 2.50" x 0.25" aluminum plate. Contact Hurst at 812-385-2564 or Fax: 812-386-7504 VArm.hurst-motors.com

Open the catalog to page 6

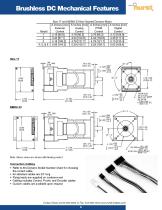

Brushless DC Mechanical Features Size 17 and NEMA 23 Non-Geared Dynamo Motor Note: Above views are shown with Analog control. Connection Cabling ♦ Refer to the Dynamo Model Number Chart for choosing • All standard cables are 24" long ♦ Flying leads are supplied on customer end ♦ Cabling includes Control, Power, and Encoder cables ♦ Custom cables are available upon request Contact Hurst at 812-385-2564 or Fax: 812-386-7504 VAfmhurst-motors.com

Open the catalog to page 7

Brushless DC Motor Controls External - The External Control Module (commutation board) simplifies the connection of an external motor drive to the Dynamo motor by providing the user with a standard set of hall signals, numerous encoder options, and a high current connector for the motor phase windings. The module is compatible with external motor drives using a 10 to 48Vdc power The External Control Module provides a standard system for rotor position sensing required by most brushless motor drives. Three hall devices spaced 120 electrical degrees apart, sense a magnetic disk which is...

Open the catalog to page 8

Hall Input Voltage (Vdc) Encoder Input Voltage (Vdc) Encoder Options (# Lines) External Control Needed Connectors & Terminals Power (Molex brand) Control/Hall (Motex brand) Fault Output Contact Hurst at 812-385-2564 or Fax: 812-386-7504 vsvM.hurst-motors.com

Open the catalog to page 9

Brush less DC Gearing Selection Guide Hurst will assist you in the selection of the best gearhead solution for your application. Some factors to consider in maximizing your application system's performance: Torque Multiplication Speed Reduction Inertia Matching Radial Loading Axial Loading Noise Spur gearheads will suit most needs in relatively low-torque applications. However, spur configurations have higher backlash and are usually less efficient than planetary types of similar construction. For constant velocity and unidirectional applications where backlash is less of a concern, spur...

Open the catalog to page 10

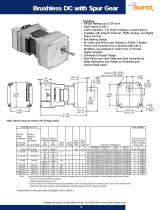

Brushless DC with Spur Gear Torque Ratings up to 200 oz-in 24Vdc Standard - For Other Voltages Consult Factory Available with Integral 'External', PWM, Analog, and Digital Motor Controls Ball Bearing Design All Gears and Pinions are Hobbed to AGMA 7 Quality Pinions are Extruded from a Special Steel with a Modified Long Addendum Tooth Form to Provide Higher Strength Extremely Compact Design Both Pinion and Gear Teeth are Case Hardened for Wear Resistance and Rotate on Hardened and Ground Steel Studs DEEP TAPPED MTG. HOLES Note: Above views are shown with Analog control Note: 1) Motor rated...

Open the catalog to page 11

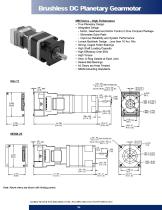

Brushless DC Planetary Gearmotor MM Series - High Performance • True Planetary Design • Integrated Design - Motor, Gearhead and Motor Control in One Compact Package - Eliminates Extra Parts - Improves Reliability and System Performance • Lowest Backlash Design.Less than 10 Arc. Min. • Strong, Caged Roller Bearings • High Shaft Loading Capacity • High Efficiency Over 90% • High Torque • Viton O-Ring Sealed at Each Joint • Sealed Ball Bearings • All Gears are Heat Treated • NEMA Mounting Standards Note: Above views are shown with Analog control. Contact Hurst at 812-385-2564 or Fax:...

Open the catalog to page 12

Brushless Planetary Gear Table PART NUMBER Model number

Open the catalog to page 13

Other Planetary Gearing JB Series - Moderate Performance Inline Planetary True planetary design Strong, caged roller bearings Sealed ball bearings All gears are heat treated NEMA mounting standards SE Series - High Performance Metric Inline Planetary • Metric and NEMA mounting available • True planetary design • High radial and axial shaft loading capacity • High torque capability • Popular metric output shaft and front bracket design EW Series - Precision Right Angle Planetary • True planetary design • Tapered roller bearings • Strong, caged roller bearings • High shaft loading capacity •...

Open the catalog to page 14All Hurst catalogs and technical brochures

-

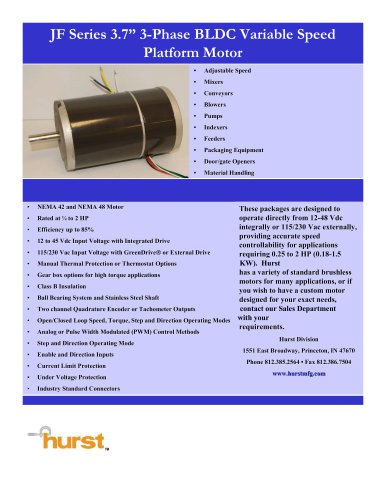

BRUSHLESS DC MOTOR FAMILY

7 Pages