Catalog excerpts

Turning Centers Technical Brochure Wth the fastest control in industry

Open the catalog to page 1

LINE UP HURCO Centers Machining Centers VM 10 Ui Plus DoubleColumn / Horizontal Machining Centers

Open the catalog to page 2

LINE UP HURCO Centers DoubleColumn / Horizontal Machining Centers Turning Centers

Open the catalog to page 3

MAX 5 CONTROL Features and Benefits WinMax® All in one Our control. Your expertise.

Open the catalog to page 4

MAX 5 CONTROL Features and Benefits >> Interactive touch screen for conversational and NC programming. >> Program management: user-centric archiving, by attached images and text search. Faster from the drawing to the finished part Shortest learning curve Fastest programming Quick overview Designed ergonomically >> Interactive touch screen for graphical representation. The workpiece can be viewed from any angle. Graphical display of tool path and part geometry, representation of all views. >> Ergonomic data entry. Fewer buttons, easier to operate. >> Rotating, tilting control panel. >>...

Open the catalog to page 5

Turning Centers TMi / TMMi Series Power and speed – the ideal machine for turning medium sized parts Cast iron frame designed with Finite Element Analysis (FEA). True 45 degree slant bed. State-of-the-art brushless AC servos Double-nut pre-tensioned ball screws. Linear rails in all axes. Maintenance-free cartridge spindle with permanently greased bearings. Bidirectional hydraulic turret. Tailstock mounted on heavy-duty box ways supplied with live center. Contact us for an individual non-binding offer. Phone: +49-(0)89-90 50 94 - 0 | info@hurco.de

Open the catalog to page 6

Machine specifications can be found on pages 16 and 17 www.hurco.euTurnining CentersTMi / TMMi Series STANDARD & OPTIONAL ITEMS

Open the catalog to page 7

The perfect combination of size and functionality >> 215 mm maximum turning diameter >> 318 mm maximum turning length >> 152 mm chuck diameter >> 45 mm draw tube diameter >> 256 mm maximum turning diameter >> 458 mm maximum turning length >> 203 mm chuck diameter >> 52 mm draw tube diameter >> 295 mm maximum turning diameter >> 694 mm maximum turning length >> 254 mm chuck diameter >> 78 mm draw tube diameter Contact us for an individual non-binding offer. Phone: +49-(0)89-90 50 94 - 0 | info@hurco.de

Open the catalog to page 8

Built tough to handle the stress of heavy duty turning >> 395 mm maximum turning diameter >> 974 mm maximum turning length >> 305 mm chuck diameter >> 104 mm draw tube diameter >> 594 mm maximum turning diameter >> 967 mm maximum turning length >> 456 mm chuck diameter >> 164 mm draw tube diameter >> 594 mm maximum turning diameter >> 1,983 mm maximum turning length >> 457 mm chuck diameter >> 164 mm draw tube diameter Contact us for an individual non-binding offer. Phone: +49-(0)89-90 50 94 - 0 | info@hurco.de

Open the catalog to page 9

Turning Centers TMi / TMMi Series A rigid and reliable machine built to last 256 mm maximum turning diameter 455 mm maximum turning length 203 mm chuck diameter 52 mm draw tube diameter Save time – turn and mill on one machine 295 mm maximum turning diameter 700 mm maximum turning length 254 mm chuck diameter 78 mm draw tube diameter Contact us for an individual non-binding offer. Phone: +49-(0)89-90 50 94 - 0 | info@hurco.de

Open the catalog to page 10

Turning Centers TMi / TMMi Series Large slant-bed lathe with live tooling 360 mm maximum turning diameter 937 mm maximum turning length 305 mm chuck diameter 104 mm draw tube diameter Contact us for an individual non-binding offer. Phone: +49-(0)89-90 50 94 - 0 | info@hurco.de

Open the catalog to page 11

Turning Centers TMXi Series TMXi Series Multi-axis lathes Power and speed – the ideal machine for machining complete medium-sized parts in one set-up Cast iron frame designed with Finite Element Analysis (FEA). True 30 degree slant bed. State-of-the-art brushless Yaskawa AC servos. Double-nut pre-tensioned ball screws. Linear rails in all axes. Maintenance-free cartridge spindle with permanently greased bearings. Bidirectional hydraulic turret. Tailstock mounted on heavy-duty box ways supplied with live center (servo driven). High horsepower and torque, fast rapids to support rigorous...

Open the catalog to page 12

Machine specifications can be found on pages 16 and 17 www.hurco.euTurning Centers TMXi Series STANDARD & OPTIONAL ITEMS

Open the catalog to page 13

Turning Centers TMXi Series Powerful productivity in a live tooling turning center >> 355 mm maximum turning diameter >> 535 mm maximum turning length >> 203 mm chuck diameter >> 64 mm draw tube diameter >> 415 mm maximum turning diameter >> 635 mm maximum turning length >> 254 mm chuck diameter >> 78 mm draw tube diameter >> 336 mm maximum turning diameter >> 527 mm maximum turning length >> Y-axis +/- 55 mm >> 203 mm chuck diameter >> 64 mm draw tube diameter Contact us for an individual non-binding offer. Phone: +49-(0)89-90 50 94 - 0 | info@hurco.de

Open the catalog to page 14

TMXi Series Built for speed and repeatability >> 375 mm maximum turning diameter >> 627 mm maximum turning length >> Y-axis +/- 55 mm >> 254 mm chuck diameter >> 78 mm draw tube diameter >> 336 mm maximum turning diameter >> 527 mm maximum turning length >> Y-axis +/- 55 mm >> 203 mm chuck diameter >> 64 mm draw tube diameter >> 375 mm maximum turning diameter >> 627 mm maximum turning length >> Y-axis +/- 55 mm >> 254 mm chuck diameter >> 78 mm draw tube diameter Contact us for an individual non-binding offer. Phone: +49-(0)89-90 50 94 - 0 | info@hurco.de

Open the catalog to page 15

Turning CentersSpecifications Information may change without notice. Optimum machine performance is reliant upon installation conditions at the facility, such as power supply, air supply, and ambient air conditions.

Open the catalog to page 16

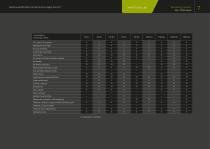

Live Tools Maximum speed (rpm) Maximum torque (Nm) Spindle power (kW @ rpm) Feeds Rapid traverse X (m/min) Rapid traverse Z (m/min) Rapid traverse Y (m/min) Rapid traverse W (m/min) Parts Catcher Maximum part size on catcher (mm) Dimensions Machine height (mm) Floor space required (width x depth in mm), doors open, incl. control unit and chip conveyor) Machine weight (approx kg)

Open the catalog to page 17All Hurco GmbH Werkzeugmaschinen catalogs and technical brochures

-

3-AXIS MACHINING CENTERS

24 Pages

-

TURNING CENTERS

20 Pages

Archived catalogs

-

5-Axis Machining Centers

20 Pages

-

5-axis maching center

20 Pages

-

Brochure en

24 Pages

-

3-Axis Machining Center

20 Pages

-

MACHINING CENTRES

32 Pages

-

Hurco Machining Centers

52 Pages

-

VMX30HSi

1 Pages

-

DCX32-5Si

1 Pages

-

DCX42i

1 Pages

-

WINMAX MILL PROGRAMMING

792 Pages

-

Hurco Lathe

48 Pages