Website:

HORIBA STEC

Website:

HORIBA STEC

Group: Horiba

Catalog excerpts

Feature Article Dissolved Oxygen Monitor (HD-960L) for Semiconductor Wet Process Dissolved Oxygen Monitor (HD-960L) for Semiconductor Wet Process Performance of the Dissolved Oxygen Monitor Used in the Semiconductor Wet Process; Low Concentration Monitoring, High Temperature, Small Amount of Sampling Volume, Chemical Resistance Kentaro INOUE The HD-960L dissolved oxygen monitor was launched for etching chemicals (HF and TMAH aqueous solutions) in semiconductor wet processes. The polarographic sensor has a guard electrode to improve the response in the low-concentration range. Optimizing the concentration of the electrolyte solution volume and configuring a current-restricting resistor for the guard electrode made it possible to measure high-temperature solutions and extend the life of the electrolyte solution. The evaluation test results showed that the saturated dissolved oxygen signal is not affected even if the chemical concentration changes, that the response to the concentration changing in the low-concentration range was fast enough, and that the signal was linear with respect to the concentration. A magnetic stirrer was installed in the flow chamber, which made it possible to take stable measurements of the dissolved oxygen, even in cases of samples with low flow rates. Introduction In semiconductor device manufacturing processes, aqueous solutions of substances such as hydrofluoric acid and TMAH (tetramethyl ammonium hydroxide) are used. The chemicals used in these processes normally contain a few μg/L to a few mg/L of oxygen, and it has been pointed out that this oxygen dissolved in the chemicals affects wafer processing. The speed of etching using TMAH and the surface uniformity are related to the dissolved oxygen concentration, and it has been found that this can affect finishing, and the dissolved oxygen in the hydrofluoric acid can corrode the copper wires and cause the device characteristics to deteriorate. As such, there is an increased need to monitor the dissolved oxygen in these chemicals. Cutting off the oxygen in the atmosphere can be achieved by purging the nitrogen, but when the oxygen in the chemicals also needs to be controlled at a low concentration, it needs to be checked using a dissolved oxygen concentration monitor. Here we would like to introduce the performance and structure of our dissolved oxygen monitor (HD-960L) for low concentrations and high temperatures that is specialized for chemicals used in semiconductor device manufacturing processes. English Edition No.47 June 2017 Measurement principle (membrane polarographic method) This dissolved oxygen monitor uses an electrochemical sensor that operates with the membrane polarographic method, and the sensor is composed of an anode, a cathode, and a guard electrode. The area inside the sensor is filled with electrolyte solution, and the area between the fluid to be measured and the sensor is segregated by a gas-permeable polymeric membrane. When the oxygen gas has passed through the membrane that separates the aqueous solution to be measured and the electrode, and diffusion allows it to reach the cathode (Au) covered by a thin electrolyte solution coat, the oxygen receives electrons from the cathode, is reduced, and becomes hydroxide ions. With the anode (Ag), part of the anode is oxidized, is ionized, and breaks away from the anode, and at the same time, leaves electrons on the anode. At this time, electrons move from the anode to the cathode, so if measurements are taken with an ammeter, a signal can be obtained that is proportional to the number of the reaction associated with the oxygen gas reduction per unit time. The main components of the electrolyte solution are a KCl aqueous solution with a pH buffer added to decrease the changes in pH that go along with the reaction. To promote the reaction, the cathode electrode is applied about -0.6 V with respect to the anode. The chemical reaction associated with oxygen gas reduc-

Open the catalog to page 1

Technical Reports tion is shown below. Cathode: O2+4e-+2H2O → 4OHAnode: 4Ag+4KCl+4OH- → 4AgCl+4KOH+4e- Current meter The chloride ions are consumed along with the reaction, which leads to the electrolyte solution having a life. At the same time, the silver on the anode gradually oxidized, but the anode has a sufficient amount secured, so this can be ignored compared to the consumption of the electrolyte solution. If the sample is a solution of hydrofluoric acid or TMAH, etc., the ions can’t move through the membrane, so they don’t affect the reaction. It is possible to correct the salinity...

Open the catalog to page 2

eature Article Dissolved Oxygen Monitor (HD-960L) for Semiconductor Wet Process Saturated DO signal with stirrer on/off 8 7 6 5 4 3 2 1 0 0 100 200 300 Sample flow rate mL/min Figure 3 Efficacy of the imbedded stirrer resulted from evaluation test (Possible to measure in low flow rate) Measuring high-temperature samples The sensor can measure high-temperature samples up to 60°C. When the temperature of the fluid supplied to the sensor increases, the volume of the electrolyte solution increases and the internal pressure increases, which causes force to push the membrane from the...

Open the catalog to page 3

HORIBA Technical Reports Figure 8 Linearity of DO in low concentration Product specifications and appearance Figure 9 shows the product appearance, and Table 1 shows the specifications. Readout English Edition No.47 June 2017

Open the catalog to page 4

eature Article Dissolved Oxygen Monitor (HD-960L) for Semiconductor Wet Process (a) sensor unit: DO-100 Figure 9 Outline view of Dissolved Oxygen monitor Table 1 Abstract of the specification than chemical concentrations, such as dissolved oxygen, will become more and more important, in addition to the conventional chemical concentration measurements. We hope that this dissolved oxygen monitor will contribute to improving the quality and yield of semiconductors. Conclusion A major feature of this product is that a resistor has been applied to the guard electrode that enables it to control...

Open the catalog to page 5All HORIBA STEC catalogs and technical brochures

-

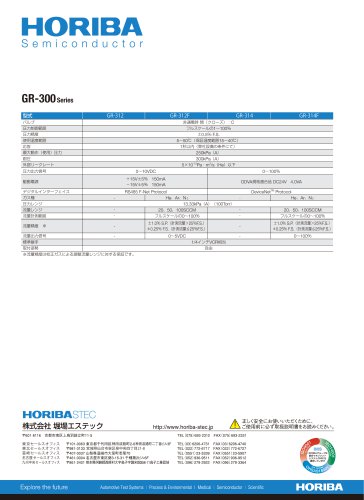

GR-300 Series

1 Pages

-

1000M Series

2 Pages

-

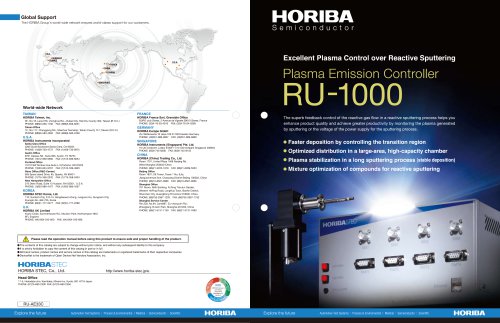

ru1000

4 Pages

-

CVS-ONE Brochure

4 Pages

-

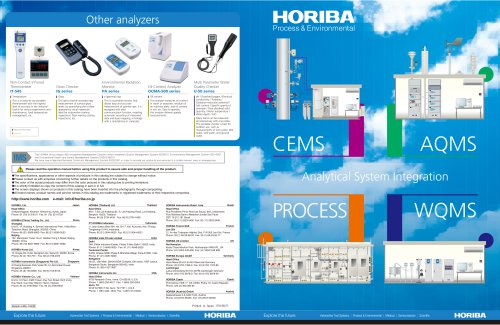

CEMS

4 Pages

-

Cathodoluminescence H-CLUE

5 Pages

-

Cathodoluminescence F-CLUE

5 Pages

-

HE-960HC

5 Pages

-

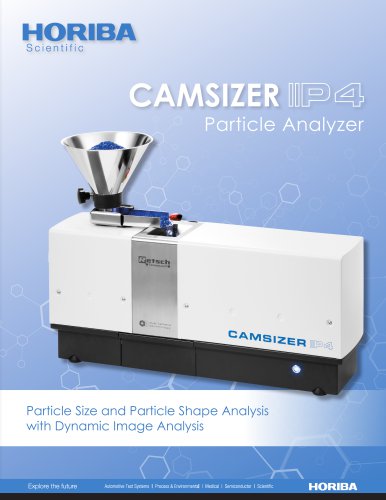

CAMSIZER X2 Brochure

12 Pages

-

CAMSIZER P4 Brochure

12 Pages

-

Brochure-TPNA-500

6 Pages

-

AP-370 Series Brochure

12 Pages

-

OMNI TERS Probes

2 Pages

-

NanoRaman Brochure

7 Pages

-

51 series Brochure

6 Pages

-

VULCAN Evo

4 Pages

-

MEDAS

8 Pages

-

OBS-ONE GS

6 Pages

-

MEXA-ONE Brochure

26 Pages

-

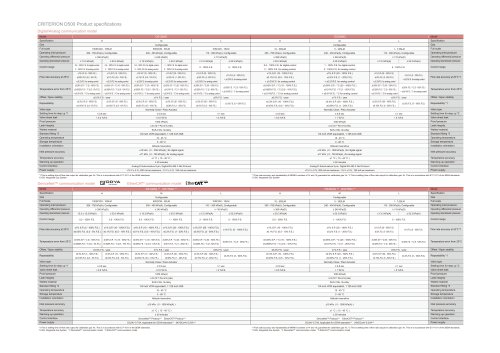

CRITERION D507 Series

3 Pages

-

Mass flow Controller & Meter

2 Pages

-

Oil analysis

3 Pages

-

Back number of CSR Reports

13 Pages

-

HORIBA Report

86 Pages

-

Soap Film Flow Meter

1 Pages

-

Analog pressure regulator

1 Pages

-

MI/MV

1 Pages

-

LV-F series

1 Pages

-

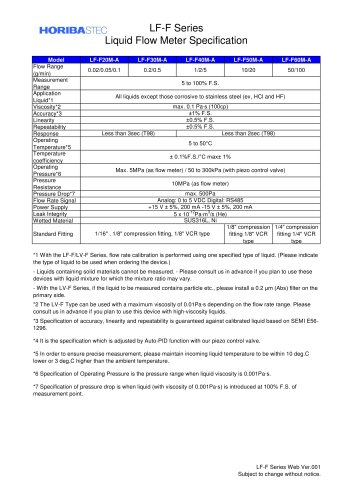

LF-F series

1 Pages

-

Criterion, D200 series

16 Pages

-

Pressure Controller

8 Pages

-

SEC-Z500MGX

16 Pages

-

Fluid Controle Equipment

4 Pages

-

Rasidual Gas Analizer

6 Pages

-

Vaporizers

8 Pages