Website:

HORIBA STEC

Website:

HORIBA STEC

Group: Horiba

Catalog excerpts

Product Introduction Development of Capacitance Diaphragm Gauge Development of Capacitance Diaphragm Gauge Sotaro KISHIDA In the deposition process or an etching process that made to be used for the fabrication of LEDs, semiconductors, FPDs and solar cells, various gases are used and the process pressure gives large effect on product quality, so the excellent corrosion resistance, and without gas dependent, and high accuracy are required to vacuum gauge . To provide solutions to these requests, HORIBA STEC has developed the Capacitance Diaphragm Gauge “VG-200 Series”, and the results of the performance evaluation were superior reproducibility and long term stability. Here, we describe the product features and performance evaluation results of the VG-200. Introduction Recently, it is becoming very important to measure and control pressure in the manufacturing processes for maintaining and control product quality in all kinds of industries. For example, in the manufacture of semiconductors, there is a process that requires control of small changes in pressure in a low-vacuum region, and vacuum meters are required to be able to measure a small pressure change with high precision. In addition, product manufacturing processes utilizing vacuum are sometimes used in the renewable energy, display, and MEMS industries. Therefore, vacuum meters are used in a wide range of industries as described above. From this, it is apparent that vacuum instrumentation with precision and stability will be more important in the future. To meet such requirements of the marketplace, we independently developed a sensor structure and signal-processing algorithm. In addition, we succeeded in the development of self-temperature-regulating, small-sized, and high-precision VG-200 series of capacitance manometers through the development of a manufacturing technology for precision welding in house as introduced below. Measurement principle of capacitance manometer The measurement principle of capacitance manometer is as follows (Figure 1): The sensor body is divided into standard chamber and English Edition No.47 April 2017 Fixed electrode Control room Measurement room Pressure to be measured Diaphragm Getter Figure 1 Diagram of Capacitance Diaphragm Gauge measurement chamber by a diaphragm. The standard chamber, which is equipped with a fixed electrode, is maintained in the vacuum state by a getter material*1. On the other hand, in the measurement chamber, if a distance between the electrode and the diaphragm changes because of a deflection of the diaphragm caused by a change in pressure, the capacitance generated between them also changes. Measuring the change in capacitance and converting it into a pressure value determines the pressure value in the measurement chamber. In addition, since the force (pressure) applied to the diaphragm can be directly converted into an output, the product performance is not dependent on the type of gas, and it is possible to measure pressure with high precision. *1: Getter material: A material that absorbs excessive gas to maintain a va

Open the catalog to page 1

HORIBA Technical Reports Features of VG-200 series capacitance manometers Product specifications Figure 2 and Table 1 show the external appearance and specifications of VG-200 series products, respectively. Sensor structure The sensor structure of VG-200 series capacitance manometers is as follows (Figure 3): The electrode is fixed to the sensor body in a way that a constant force is applied to the entire electrode in the same direction on a consistent basis without being jointed to the sensor body directly. Using this electrode structure that we independently developed allowed us to...

Open the catalog to page 2

roduct Introduction Development of Capacitance Diaphragm Gauge causing measurement error. We have solved this problem by implementing a unique circuit, which is designed to use a sampling circuit whose phase is synchronized with the output pulse from a sensor to detect a pulse amplitude always in the same phase. This circuit lowers the factors for measurement error and reduces the effects of disturbances that occur during analog computing that achieved higher resolution. In addition, we changed the structure of this circuit based on the premise of eliminating inverting and non-inverting...

Open the catalog to page 3

HORIBA Technical Reports HORIBA Technical Reports Pressurization (times) Figure 7 Test result of proof pressure times, and Figure 7 shows the output stability when an excessive pressure (350 kPa [abs]) is continuously applied for an hour. With the use of a metal diaphragm with superior mechanical properties, it was confirmed that the output shift could be minimized even when an excessive pressure was applied to the sensor and was very small even when the sensor was exposed to the atmosphere repeatedly. Conclusion We succeeded in the development of a small-sized, high-precision, and...

Open the catalog to page 4All HORIBA STEC catalogs and technical brochures

-

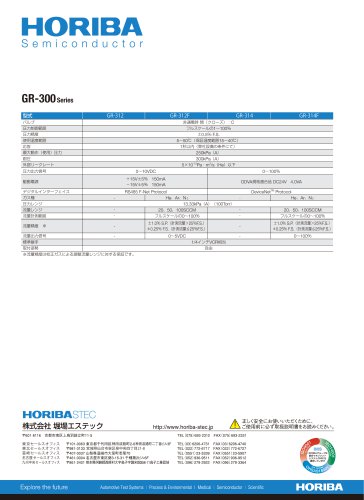

GR-300 Series

1 Pages

-

1000M Series

2 Pages

-

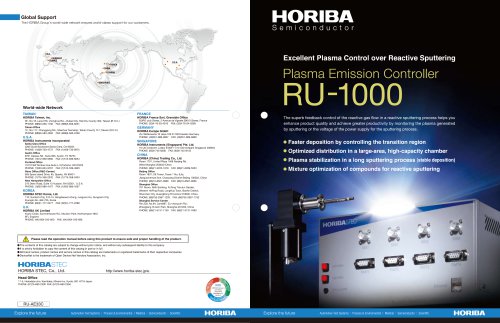

ru1000

4 Pages

-

HF HD-960L

5 Pages

-

CVS-ONE Brochure

4 Pages

-

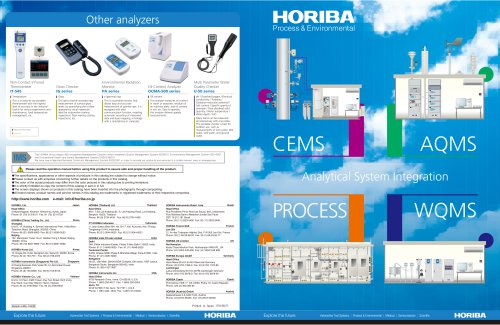

CEMS

4 Pages

-

Cathodoluminescence H-CLUE

5 Pages

-

Cathodoluminescence F-CLUE

5 Pages

-

HE-960HC

5 Pages

-

CAMSIZER X2 Brochure

12 Pages

-

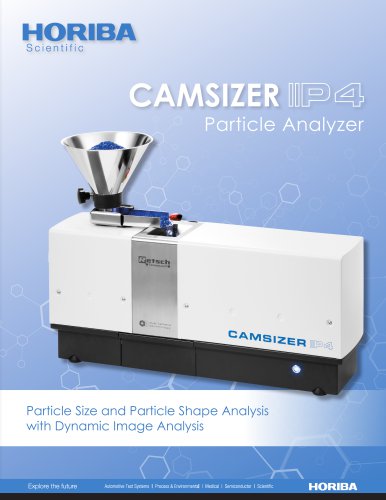

CAMSIZER P4 Brochure

12 Pages

-

Brochure-TPNA-500

6 Pages

-

AP-370 Series Brochure

12 Pages

-

OMNI TERS Probes

2 Pages

-

NanoRaman Brochure

7 Pages

-

51 series Brochure

6 Pages

-

VULCAN Evo

4 Pages

-

MEDAS

8 Pages

-

OBS-ONE GS

6 Pages

-

MEXA-ONE Brochure

26 Pages

-

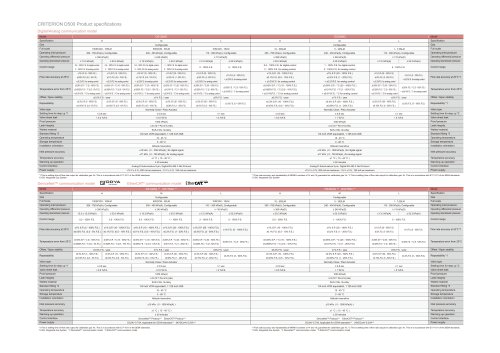

CRITERION D507 Series

3 Pages

-

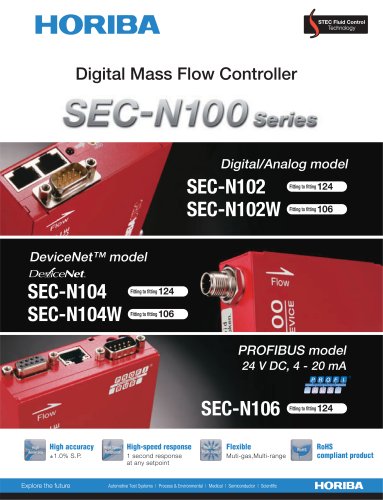

Mass flow Controller & Meter

2 Pages

-

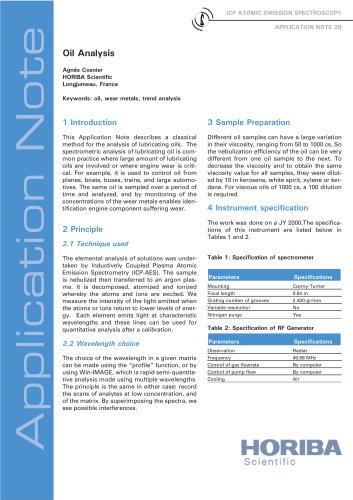

Oil analysis

3 Pages

-

Back number of CSR Reports

13 Pages

-

HORIBA Report

86 Pages

-

Soap Film Flow Meter

1 Pages

-

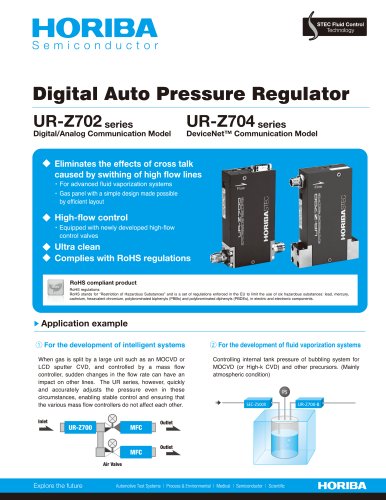

Analog pressure regulator

1 Pages

-

MI/MV

1 Pages

-

LV-F series

1 Pages

-

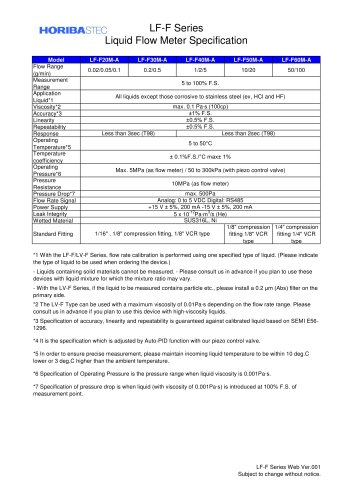

LF-F series

1 Pages

-

Criterion, D200 series

16 Pages

-

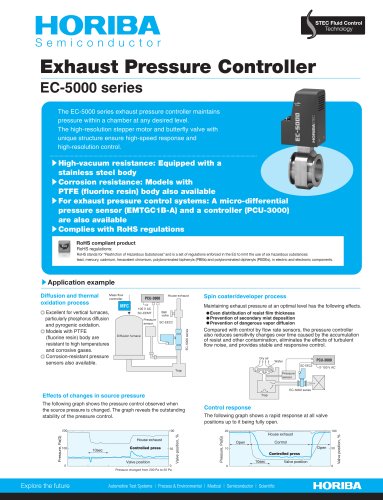

Pressure Controller

8 Pages

-

SEC-Z500MGX

16 Pages

-

Fluid Controle Equipment

4 Pages

-

Rasidual Gas Analizer

6 Pages

-

Vaporizers

8 Pages