Website:

HORIBA STEC

Website:

HORIBA STEC

Group: Horiba

Catalog excerpts

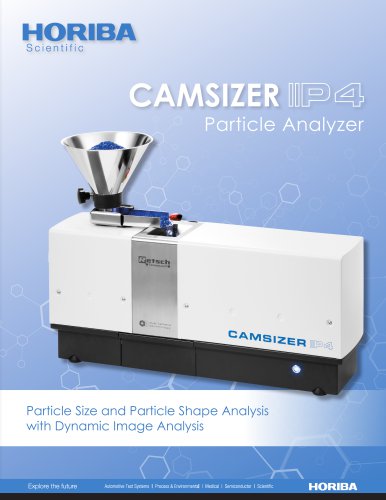

CAMSIZERParticle Analyzer Technou Particle Size and Particle Shape Analysis with Dynamic Image Analysis Explore the future Automotive Test Systems I Process & Environmental I Medical I Semiconductor I Scientific HORIBA

Open the catalog to page 1

Precise Measurement of Particle Size and Shape with the CAMSIZER® X2 The quality control of fine powders can be substantially improved with the CAMSIZER X2. More precise and faster analysis of particle size and particle shape helps to improve product quality, reduce rejected lots and save on costs. • Measuring range from 0.8 μm to 8 mm without hardware adjustment The CAMSIZER X2 is an advancement of the wellproven optical measurement system CAMSIZER for finer samples. The basic differences include higher resolution of the optical systems and improved options for the sample feeding. Fine...

Open the catalog to page 2

New Optical System Bright light sources, fast cameras with high resolution, and particularly the new optical split view concept make the CAMSIZER X2 a superior analyzer. The patented split view optical design arranges the optical paths of the two cameras perpendicular to the direction of movement of the dispersed particles. The monochromatic light beams of the two pulsed LED light sources are focused and collimated to illuminate the detection area of each camera respectively (Basic and Zoom). Both light beams are combined with a prism so that they illuminate their respective, overlapping...

Open the catalog to page 3

Evaluation and Documentation HORIBA supplies the CAMSIZER X2 with a powerful, process-oriented control and evaluation software which offers flexible data export to the customer’s LIMS. A major advantage is the evaluation of the results in real-time. Graphical representation of the results is available while the measurement is still in progress. At the same time the measurement process can be checked visually by observing the digital images. All particle images and parameters are evaluated directly during measurement and are also saved by the software module “Particle X-Plorer” in a...

Open the catalog to page 4

NEW: Particle X-Plorer with 3D Cloud The new structure of the CAMSIZER X2 software not only allows for data evaluation in real-time but also for the storage of large amounts of image data in the Particle X-Plorer database. Particle images with noteworthy characteristics may be extracted and displayed at a later time. Similar image libraries are commonly used for documentation purposes in static image analysis (microscopy). This method allows for measurement of only a small number of particles. The CAMSIZER X2 particle database, however, handles millions of single particle images for each...

Open the catalog to page 5

Modular Design for Optimized Measurement Conditions The CAMSIZER X2’s modular “X-Change” system offers three alternative dispersion methods, permitting the selection of the optimum method for each sample type: ■ Air pressure dispersion ■ Gravity dispersion ■ Wet dispersion The modules and plug-in cartridges are easily exchanged in one minute allowing for rapid switching between dispersion methods. Sieve Analysis, Laser Diffraction, Static, or Dynamic Image Analysis? A comparison of measurement techniques Performance Features Wide dynamic measurement range Reproducibility and repeatability...

Open the catalog to page 6

Air Pressure Dispersion with “X-Jet” The dispersion, that means the deagglomeration of the particles prior to passing through the measurement area, can be a crucial precondition for a proper measurement of the particles. Thanks to the flexible pressure adjustments of the “X-Jet” plug-in cartridge each material can be measured under optimum conditions. Small particles have a relatively large surface area which increases the effects of adhesion forces or electrostatic charges, and can lead to aggregation of the particles. When passing through the nozzle, the sample material is dragged along...

Open the catalog to page 7

Gravity Dispersion with “X-Fall” Flowable, unagglomerated samples can be analyzed by using the “X-Fall” plug-in cartridge. In this mode, the particles fall from a chute through the field of view of the two cameras accelerated only by gravity. Thanks to the comparably low speed of the particles, the large field of view and the high frame rate, the detection efficiency is very high, even for large particles up to 8 mm. Only a few coarser particles in the sample are sufficient for reliable, reproducible detection. After the measurement, the sample materials fall into a collection box and are...

Open the catalog to page 8

Wet Dispersion with the “X-Flow” Module The wet module “X-Flow” analyzes samples in the range from 0.8 μm to 1 mm in suspensions or emulsions. An advantage of this module is the small sample volume which is required. A low particle concentration in the dispersion medium, for example, 20 mg/l is already sufficient. It provides enough particles for a reproducible result in only 1 minute. Therefore, this module is highly suitable for applications involving pharmaceuticals or explosives. Here only a limited amount of sample material is available or advisable for safe operation. It can also be...

Open the catalog to page 9

Key Features Wide Dynamic Measuring Range Particle shape Particle size Aspect ratio The initial material is almost spherical with a b/l ratio of more than 0.95 (red curve). The increasing fraction of broken particles can be derived directly from the graph at the threshold value 0.95. Aspect ratio Size Results 100% Compatible with Sieve Analysis X-Dry with X-Jet * Sieve analysis Catalysts: Non-spherical (broken) particles can be detected by looking at parameters such as aspect ratio (breadth divided by length, b/l) or symmetry. The graphic shows a series of measurements with increasing...

Open the catalog to page 10

Comparison to laser diffraction and sieve analysis The laser diffraction curve shows a broader distribution. For the large particles around 0.5 mm the laser diffraction measurement shows oversized particles not visible in sieve analysis results. Measurement of particle width is identical to sieve analysis. Laser diffraction measurements are based on the assumption that all particles are spherical. Therefore, it is not possible to differenciate parameters such as “diameter” and “length”. The curves shown are typical for samples containing non-round or longish particles. – w idth – l ength –...

Open the catalog to page 11All HORIBA STEC catalogs and technical brochures

-

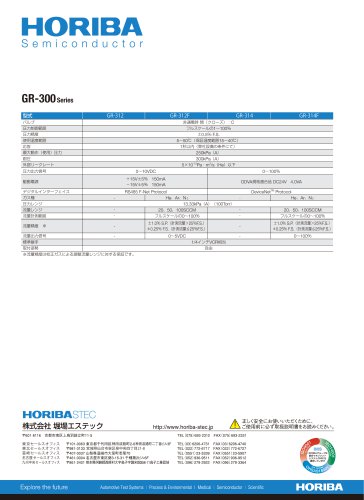

GR-300 Series

1 Pages

-

1000M Series

2 Pages

-

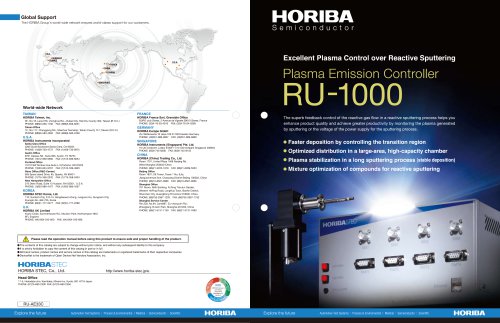

ru1000

4 Pages

-

HF HD-960L

5 Pages

-

CVS-ONE Brochure

4 Pages

-

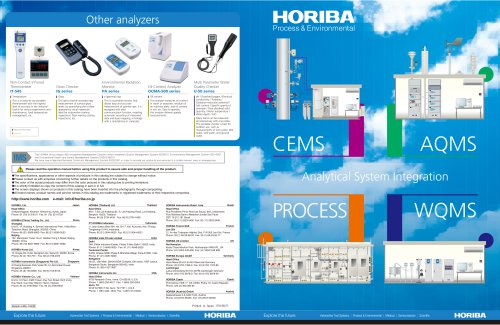

CEMS

4 Pages

-

Cathodoluminescence H-CLUE

5 Pages

-

Cathodoluminescence F-CLUE

5 Pages

-

HE-960HC

5 Pages

-

CAMSIZER P4 Brochure

12 Pages

-

Brochure-TPNA-500

6 Pages

-

AP-370 Series Brochure

12 Pages

-

OMNI TERS Probes

2 Pages

-

NanoRaman Brochure

7 Pages

-

51 series Brochure

6 Pages

-

VULCAN Evo

4 Pages

-

MEDAS

8 Pages

-

OBS-ONE GS

6 Pages

-

MEXA-ONE Brochure

26 Pages

-

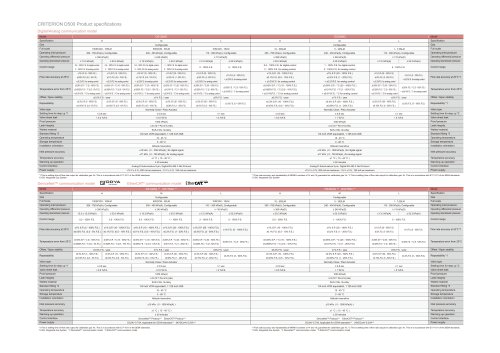

CRITERION D507 Series

3 Pages

-

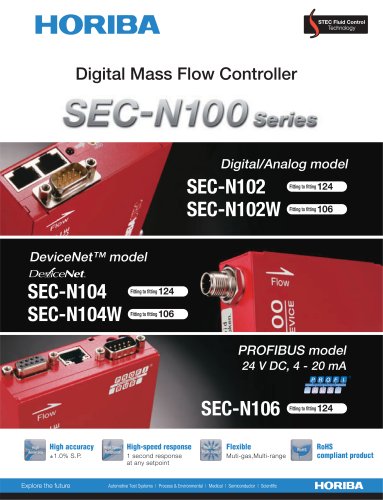

Mass flow Controller & Meter

2 Pages

-

Oil analysis

3 Pages

-

Back number of CSR Reports

13 Pages

-

HORIBA Report

86 Pages

-

Soap Film Flow Meter

1 Pages

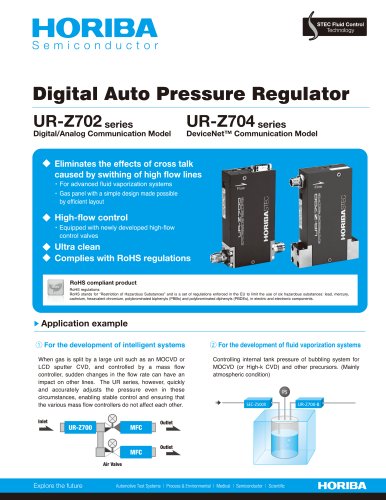

-

Analog pressure regulator

1 Pages

-

MI/MV

1 Pages

-

LV-F series

1 Pages

-

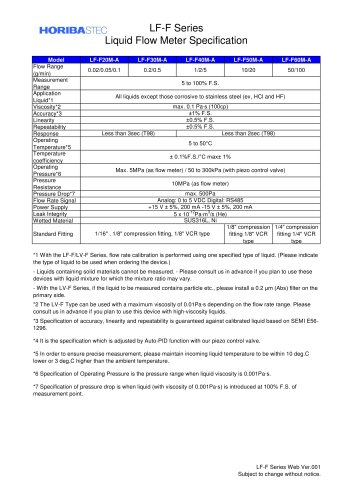

LF-F series

1 Pages

-

Criterion, D200 series

16 Pages

-

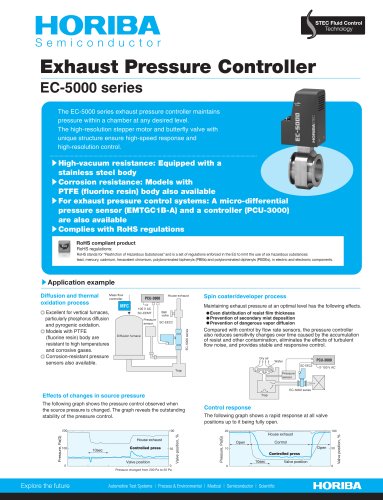

Pressure Controller

8 Pages

-

SEC-Z500MGX

16 Pages

-

Fluid Controle Equipment

4 Pages

-

Rasidual Gas Analizer

6 Pages

-

Vaporizers

8 Pages