Website:

MOLDINO Tool Engineering Europe GmbH

Website:

MOLDINO Tool Engineering Europe GmbH

Group: HITACHI

Catalog excerpts

Super Ball End Mill ASB For machining pre-hardened steel or tempered steel Cutting innovation For high-efficient machining of mild steel Introducing new JP/JS coating Introducing an epoch-making ball end mill for heavy machining, breaking through to a new machining era. sista Low-re

Open the catalog to page 1

Item Code ffiffll'V'tt—h Inserts jH^J Master Insert Item Code Flutes Item Code Flutes Peripheral Insert Item Code Flutes 0 : Stocked Items. No Mark : Manufactured upon request only.

Open the catalog to page 2

Super Ball End Mill ASB (Sffl^Vtt—h Inserts Master Insert 'Mwas-fy) ™|hnick <M,wstS"<T> ™|NNICK LEN NAND Low-resistance type Low-resistance type l^rJlS Peripheral Insert With nick {tttt&tt*i*f-rt Wfth nick {miff i^-t^ ~1\ With nick Left hand type Low-resistance type Low-resistance type

Open the catalog to page 3

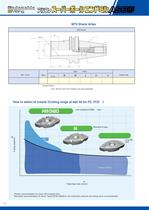

•ED : SBPSKffiTfo • : Stocked Items. [)±sl UV?W—JI/-i7^V;\"lJSUJSISroffli:fty^"9'o [Note]Wrench and Tool Clamper are sold separately. >tt—h<DffiU#l J (7JU77/1t-JU05O (D FC.FCD OijDIMM) How to select of inserts (Cutting range of ball 050 for FC, FCD) Table feed rate (mm/min) Primary recommendation for chuck: MT-5 special arbor Secondary recommendation for chuck: Takura BT50-HMD50.8-120 combination side lock and milling chuck is recommended

Open the catalog to page 4

Super Ball End Mill ASB Features Axial rake effect provides a 10 to 20% reduction in cutting resistance compared to our company's previous products. Range in which Ar becomes negative Conventional BCU product R R rise moves forward. Conventional BCU product projecting R direction Comparison of cutting resistance for 50 ball vc =141m/min n Inserts N Resultant force Inserts N3 Resultant force Our company's previous product Resultant force Corresponding Company A product Resultant force Corresponding Company B product Resultant force

Open the catalog to page 5

. . .. . .. . . . ... . . . Solves problems which may occur in heavy machining Inserts are firmly fixed in place by the unprecedented r ' ' a double-clamp system. Step between main and sub inserts is low, enabling smooth plunge machining in scan processing. Body durability has been greatly improved (compared to our company's previous products) by using a new type of steel. Previous steel type B Previous steel type A Actual example using 020 ball EM tDI'lJML, Cutting Length(m) tDI'lJBf FJ3T, Cutting Time(min) )M^DP Long life Combining these features provides superlative long life compared to...

Open the catalog to page 6

Super Ball End Mill ASB I HJKctlo^) Field Data Processing shapes MT type Recommended Cutting Conditions (Hilly Side Milling SEUlBlilfly Depth side Milling Carbon & Alloy Steels Cutting speed Feed rate per flute Hardened & Pre-Harden Steels Cutting speed Feed rate per flute Cast Iron Cutting speed Feed rate per flute These conditions are for general guidance; in actual machining conditions adjust the parameters according to your actual machine and work-piece conditions. (1) For long type please reduce speed and feed by 70%. (2) If using a machine with less than 15kw power reduce data to 60%...

Open the catalog to page 7

A Sf IfflCil Attentions on Safety 1. Cautions regarding handling (1) When removing the tool from the case (package), be careful not to drop it on your foot or drop it onto the tips of your bare fingers. (2) When actually setting the inserts, be careful not to touch the cutting flute directly with your bare hands. 2. Cautions regarding mounting (1) When preparing for use, be sure that the inserts are firmly mounted in place and that they are firmly mounted on the arbor, etc. (2) If abnormal chattering occurs during use, stop the machine immediately and remove the (1) Before use, confirm the...

Open the catalog to page 8All MOLDINO Tool Engineering Europe GmbH catalogs and technical brochures

-

CBN-EPSB/CBN-EPSR

16 Pages

-

EPBTS

12 Pages

-

EMXR

16 Pages

-

EMXA

12 Pages

-

EPDRF-TH

12 Pages

-

EPDBPE-ATH

20 Pages

-

Epoch TH Power Mill

12 Pages

-

Radius Precision ARPF

20 Pages

-

Carbide Thread Mill series

16 Pages

-

SCE-R

6 Pages

-

RV type

12 Pages

-

ABPFN type

6 Pages

-

TD4N type

8 Pages

-

EHHB-ATH

8 Pages

-

EPCDS

4 Pages

-

Epoch CFRP series

6 Pages

-

EPSM-PN/ EPSW-PN

32 Pages

-

GALLEA series

24 Pages

-

WHMB-TH

12 Pages

-

EMBE-ATH/EMBPE-ATH

16 Pages

-

ETR(P)-TH,ETM(LN/P)-TH

16 Pages

-

EPDRE-ATH

24 Pages

-

CBN-EHB

12 Pages

-

EHHBE-TH3

8 Pages

-

TD6N type

12 Pages

-

EB4HR-ATH

12 Pages

-

EHX

12 Pages

-

EPHB-PN

8 Pages

-

EHHRE-TH3

8 Pages

-

EDT

16 Pages

-

EHSE-TH

8 Pages

-

NSB

12 Pages

-

WHNSB-TH

20 Pages

-

EMSBS

8 Pages

-

Ball Precision F ABPF type

16 Pages

-

Carbide Drill for SR machining

12 Pages

-

Radius Mill RD16B Type

8 Pages

-

GS4TN type

4 Pages

-

Red Screw Arbor

8 Pages

-

ABP4F

8 Pages

-

EPDBE-PN/ATH EPDSE-PN/ATH

32 Pages

-

EPDBEH-TH3

20 Pages

-

MINIATURE DRILL WHMB

8 Pages

-

Epoch ® Combination Rib Ball

8 Pages

-

PRODUCTS CATALOGUE 2015 - 2016

1070 Pages

-

Carbide Non Step Borer series

28 Pages

-

Drills for High-hardness Steels

16 Pages

-

Face Mill : ASF type

8 Pages

-

Face Mill : AFE45 type

8 Pages

-

Ball Precision F : ABPF type

16 Pages

-

Radius Precision : ARPF type

12 Pages

-

Polish Mill V Type : ASPV Type

20 Pages

-

Roughing End Mill : AME Type

12 Pages

-

Radius Mill : AR type

20 Pages

-

JM4060

4 Pages

-

Epoch Micro?End Mill TH : EMM-TH

24 Pages

-

Epoch Deep Radius Evolution

24 Pages

-

Epoch Deep Ball Evolution Hard

16 Pages

-

Epoch Micro Drill?EMD

24 Pages

-

Radius Mill : ASR type

20 Pages

-

Super Excellent MINI : ASM type

12 Pages

-

Epoch "Mirus" Series

12 Pages

-

Epoch G Turbo

8 Pages

-

Roughing End Mill AME Type

12 Pages

-

Z Plunging Borer?ZPB-TH

4 Pages

-

Face Mill AFE45

8 Pages

-

Epoch Micro Step Borer S

8 Pages

-

Epoch CBN End Mill series

16 Pages

-

HX3505 & HX3515

6 Pages

-

GX2140

4 Pages

-

Epoch "Panacea"

16 Pages

-

Epoch Deep Evolution series

24 Pages

-

Epoch SUS End Mill series

32 Pages

-

Epoch Pencil Deep Ball Evolution

20 Pages

-

Epoch Deep Radius F

12 Pages

Archived catalogs

-

Carbide End Mills

280 Pages

-

HSS Non Step Borer

36 Pages

-

Surface Treatment Tribec

8 Pages

-

CBN End Mills

20 Pages

-

Re-grinding & Re-coating

20 Pages

-

Cutters

10 Pages

-

Reamers

16 Pages

-

HSS End Mills

98 Pages

-

Turning Inserts

44 Pages

-

Threading Tools

6 Pages

-

Indexable Tools

160 Pages

-

Milling Inserts

16 Pages

-

Micro Series for Micro Machining

14 Pages

-

2009-2010 New Products Guide

5 Pages