Catalog excerpts

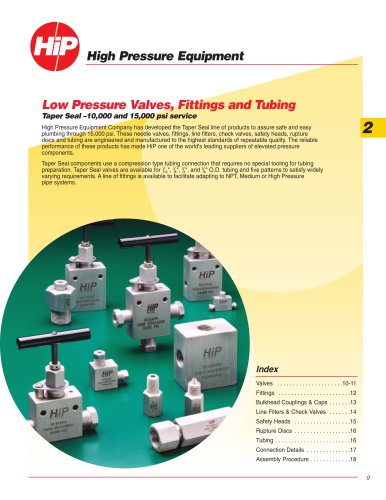

High Pressure Equipment Low Pressure Valves, Fittings and Tubing Taper Seal –10,000 and 15,000 psi service High Pressure Equipment Company has developed the Taper Seal line of products to assure safe and easy plumbing through 15,000 psi. These needle valves, fittings, line filters, check valves, safety heads, rupture discs and tubing are engineered and manufactured to the highest standards of repeatable quality. The reliable performance of these products has made HiP one of the world's leading suppliers of elevated pressure components. Taper Seal components use a compression type tubing connection that requires no special tooling for tubing preparation. Taper Seal valves are available for 1/16", 1/8", 1/4", and 3/8" O.D. tubing and five patterns to satisfy widely varying requirements. A line of fittings is available to facilitate adapting to NPT, Medium or High Pressure pipe systems. Index Valves . . . . . . . . . . . . . . . . . . . . .10-11 Fittings . . . . . . . . . . . . . . . . . . . . . . .12 Bulkhead Couplings & Caps . . . . . . .13 Line Filters & Check Valves . . . . . . .14 Safety Heads . . . . . . . . . . . . . . . . . .15 Rupture Discs . . . . . . . . . . . . . . . . . .16 Tubing . . . . . . . . . . . . . . . . . . . . . . . .16 Connection Details . . . . . . . . . . . . . .17 Assembly Procedure . . . . . . . . . . . . .18

Open the catalog to page 1

Taper Seal Needle Valves 10,000 and 15,000 psi service Compression type tubing connections for 1/16", 1/8", 1/4", and 3/8" O.D. tubing. Requires no special tooling for tubing preparation (simply cut off, deburr, and insert tubing into connection). Connection details are shown on page 17. Non-rotating slotted stems are standard on AF4 and AF6 for on-off service and ensure long life on valve seats. Regulating tip stems are available at no additional cost, add - REG to the catalog number. Glands and sleeves are supplied with each valve unless otherwise requested (glands and sleeves shown on...

Open the catalog to page 2

High Pressure Equipment Conn. Orifice Three Way Valves / Two Pressure Connections K Three Way Valves / One Pressure Connection Three Way / Two Stem Connection Valves J F Replaceable Seat Valve High Pressure Equipment Company www.HighPressure.com 2955 W. 17th Street • Erie, PA 16505 U.S.A. • Phone: (814) 838-2028 • 1-800-289-7447 • Fax: (814) 838-6075 • Email: sales@highpressure.

Open the catalog to page 3

Taper Seal Valves Glands/Sleeves/Plugs/Elbows/Tees/Crosses A complete range of elbows, tees, and crosses is available for all of the tubing connection sizes. Material is high tensile 316 stainless steel. Standard tubing glands and sleeves are furnished unless otherwise specified. Connection Components Catalog No. Tube Size Tube Size Tube Size Taper Seal Elbows Taper Seal Tees Taper Seal Crosses

Open the catalog to page 4

High Pressure Equipment Bulkhead Couplings Bulkhead couplings are designed specifically for passing a tubing connection through a panel or steel barricade. These couplings include a locknut as shown. Material is high tensile 316 stainless steel. Standard tubing collars and glands are included unless otherwise specified. Hole Diameter Caps Tubing end caps are offered for use in sealing off tubing ends either for temporary use or permanent use, such as on small volume reservoirs. Standard material is high tensile 316 stainless steel. Standard tubing collars and glands are provided unless...

Open the catalog to page 5

Taper Seal Valves Line Filters The line filters as shown utilize sintered stainless steel filter discs (AF2 & AF1 – 3 pc./set, AF4 & AF6 – 4 pc./set). Porosities are available as per the chart to the right. If not otherwise specified, 100 micron filter discs are supplied. (One micron = 0.001 millimeters). Material of bodies and end covers is high tensile 316 stainless steel. Standard glands and sleeves are provided unless otherwise specified. " /16 TAPER SEAL /8" TAPER SEAL /4" TAPER SEAL /8" TAPER SEAL Ball Check Valves Ball type check valves insure flow in one direction only. Material for...

Open the catalog to page 6

High Pressure Equipment Safety Heads A choice of three safety head designs is available: male inlet, female inlet (straight), and tee type. The male inlet design can be inserted directly into the tubing connections of valves and various fittings such as tees and crosses, or located in pressure vessels. Outlet connections on all sizes are 3/8" pipe (NPT). This outlet may be connected to a suitable discharge line to vent pressure to a safe location in the event of bursting of the rupture disc. Torque required for sealing rupture discs will range from 40 to 60 foot pounds, depending upon...

Open the catalog to page 7

Taper Seal Valves Rupture Discs 1" /4 Angled Seat Standard rupture discs are available from stock in burst pressures as listed in the chart below. Taper seal pressures are shaded. These discs are 316 stainless steel (except for 1000 psi which are inconel) and may be used with any of the safety heads shown. Note that these rupture discs are supplied with a range of plus 6% and minus 3% of specified burst pressure. Samples of each batch are then tested and typically the actual average burst pressure is stamped on an accompanying metal tag. There is a +/- 5% burst tolerance applied after the...

Open the catalog to page 8

High Pressure Equipment Taper Seal Connections 10,000 and 15,000 psi service Taper Seal connections are available for 1/16", 1/8", 1/4", and 3/8" O.D. tubing. No special tubing preparation is required – simply cut tubing to desired length, deburr and assemble. The 1/8", 1/4", and 3/8" sizes utilize a two-piece sleeve which is supplied partially assembled. When the connection is assembled, the outer sleeve portion is permanently compressed over the inner Tubing Gland Sleeve portion to rigidly lock the sleeve onto the tubing. Note that the sleeve is not forced to bite into the tubing, but...

Open the catalog to page 9

Taper Seal Valves Taper Seal Assembly Procedure – AF2, AF4 and AF6 Connections 1. Lubricate the male threads of the Taperseal gland, and the back of the outer collar on the sleeve with a process compatible lubricant. 2. Put a small amount of lubricant on the area where the outer collar and inner sleeve come in contact with each other. This will reduce the friction when the outer collar slides over the inner sleeve. 3. Assemble the Taperseal gland, sleeve and tubing into the component or assembly mandrel and tighten finger-tight. 4. Using the appropriate size wrench, rotate the gland nut...

Open the catalog to page 10All HIP catalogs and technical brochures

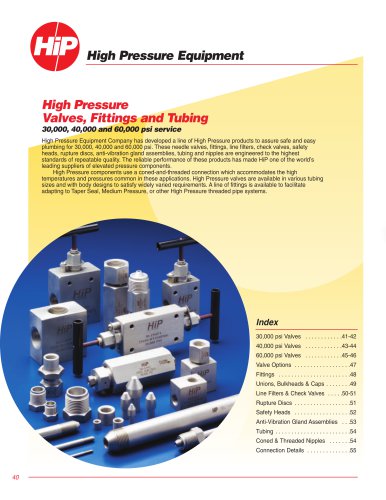

-

Condensed Catalog

8 Pages

-

LF series

12 Pages

-

HF series

16 Pages