Catalog excerpts

The safe decision. hima/process_automation/communication

Open the catalog to page 1

hima/process_automation/communication To ensure cost-effectiveness in the long-term, HIMA has always embraced the concept of integration based on open and internationally-accepted communication standards. The benefits of open communication compared to vendor-specific, proprietary protools and technology are obvious: Reduced integration costs Reduced integration risks Consistent data organisation, transparency Fast availability of data Cuts programming and engineering times Less training required Less maintenance required Long-term independence and return on investment, even if extension or...

Open the catalog to page 3

OPC DA server functions: Data transmission at 100 Mbit/s OPC server can update data <_ 20 ms HIMA systems are controlled and monitored via control systems Connection status monitored via the control system Supports server and tag browsing Allows data to be prioritised OPC is a world-wide, open and standardised data interface. It was standardised by the OPC Foundation and is based on Windows technology (OLE, COM and DCOM). The data from the HIMA systems is made available to any OPC client via HIMA OPC server. HIMA can supply an OPC server based on the OPC Data Access specification and one...

Open the catalog to page 4

MODBUS RTU transmission at up to configuration Transmission via RS485 interface MODBUS TCP transmission at 100 Mbit/s Transmission over all standard Ethernet The HART protocol provides an easy way to send diagnostic/status information and to program HART-compatible sensors/actuators. The HART signals are modulated on to a 4...20-mA signal. There are special requirements relating to the transmission and extraction of HART data from safety-related loops. This is because the HART protocol can be used to modify the parameter assignments of field devices, such as measuring ranges or operating...

Open the catalog to page 5

hima/process_automation/communication/abb Functions Reading and writing process signals Transmitting signals with time stamp Time-synchronising all HIMA and ABB systems Displaying the process signals and events together in the ABB Operate IT stations Redundant structure is possible Ethernet (TCP/IP) Ethernet e.g. AC 800F H41q/H51q e.g. S 800/S900 e.g. CMC 70 Ethernet Interfacing references: ABB 800xA ABB Symphony Infi 90 ABB Symphony Melody ABB Freelance ABB Masterpiece ABB Advant OCS/MOD 300 ABB Protocol P ABB Compact

Open the catalog to page 6

Functions Reading and writing process signals Transmitting signals with a time stamp Displaying the signals and events together in the Emerson DeltaV system Redundant structure is possible hima/process_automation/communication/emerson Ethernet (TCP/IP) Ethernet Ethernet DeltaV controller H41q/H51q DeltaV HIMA OPC server

Open the catalog to page 7

PROFIBUS DP hima/process_automation/communication/foxboro Functions Data transmission at up to 12 Mbit/s (set using DIL switches) Self-configuring HIMA Profibus module Off-the-shelf ELOP II function block for redundancy management GSD file for parameter assignments in the master Redundant structure is possible Certified by the PNO HIMatrix I/A system bus HIMA H41q/H51q HIMA Planar4 I/A controller FBM 223 I/A series The PROFIBUS interfacing is programmed in the Foxboro system

Open the catalog to page 8

Interfacing references: Honeywell Experion PKS Honeywell PlantScape Honeywell TDC 3000/TPS hima/process_automation/communication/honeywell Honeywell FTE Ethernet Honeywell Experion PKS server Experion PKS Functions Reading and writing process signals Transmitting signals with a time stamp Displaying the signals and events together in the Honeywell Experion PKS system Redundant structure is possible H41q/H51q HIMA OPC server HIMA diagnostics in Experion PKS

Open the catalog to page 9

Functions Data transmission at up to 12 Mbit/s Self-configuring HIMA PROFIBUS modules CFC blocks for HIMA systems in the PCS 7 control system GSD file for parameter assignments in the PROFIBUS Master Redundant structure is possible Certified by the PNO (PROFIBUS User Organisation) Interfacing references: Siemens PCS 7 Siemens S7-400 Siemens S7-300 Siemens S5 Teleperm M Teleperm XP Win CC Standardised ELOP II function block for redundancy management PROFIBUS DP redundant hima/process_automation/communication/siemens Industrial Ethernet HIMA H41q/H51q e.g. ET 200 e.g. ET 200 Siemens S7-400...

Open the catalog to page 10

Interfacing references: Centum CS 3000 Centum CS 1000 hima/process_automation/communication/yokogawa Ethernet Functions Reading and writing process signals Transmitting signals with time stamp Data transmission at 10/100 MBit/s Automatic configuration of the HIMA systems All HIMA systems can be linked Redundant structure is possible Proven all around the world Configuration of MODBUS communication in the Yokogawa system ALE HIMatrix Ethernet (TCP/IP) V-Net/IP HIMA H41q/H51q CS-3000 controller HIMA Planar4 HIMA CS 3000 OPC A&E

Open the catalog to page 11

RS485 Interfacing with MODBUS RTU HIMA system as MODBUS Slaves Reading and writing process signals Transmitting signals with time stamp (WS) Data transmission at 57,600 Bit/s Redundant structure is possible hima/process_automation/communication/displays HIMatrix HIMatrix HIMatrix HIMatrix HIMA Planar4 HIMA H41q/H51q iFix/WS Ethernet Interfaction with MODBUS TCP Reading and writing process signals Data transmission at 100 Mbit/s Use of existing Ethernet networks Use of the entire Ethernet functionality Transmitting signals with time stamp (WS)

Open the catalog to page 12

Functions Process and HART signals are split – without feedback – in the HIMA Ex separator Up to 8 HART devices are collected in the HIMA-HART multiplexer The HART information thus collected is forwarded to the HART-OPC server via an RS485 interface The Ex separator is SIL-certified It is also possible to use conventional HART devices due to the disable function for parameter setting data RS485 Process signals Safe process signals hima/process_automation/communication/hart HART signals Multiplexer Extraction of HART data Actuator Sensor Control system & HART OPC server HART signals Process...

Open the catalog to page 13

Key features of safeethernet: Data transmission at up to 100 Mbit/s Ensures the shortest response times within the required safety time No restrictions with respect to physical distance Standard Ethernet components from any vendor may be used Ethernet network technology guarantees flexibility of planning, commissioning, maintenance and extension Ethernet from the control level through to the field level ensures data transparency Up to 64 systems can be networked per Ethernet segment Redundant structure is possible For networking H41q/H51q or HIMatrix systems Key features of HIPRO-S: Data...

Open the catalog to page 14All HIMA catalogs and technical brochures

-

HART COMMUNICATION PROTOCOL

5 Pages

-

HIMax HART SOLUTION

2 Pages

-

HIMatrix CSG

2 Pages

-

HIJunctionBox

2 Pages

-

WIRELESS

2 Pages

-

HICore 1 EVALUATION KITS

2 Pages

-

HIQuad X

2 Pages

-

HIMax

11 Pages

-

HIMax product catalogue

108 Pages

-

Subrack F60

26 Pages

-

IMatrix F30

52 Pages

-

HIMatrix F1 DI 16 01

42 Pages

-

HICore

2 Pages

-

Power supply PS1000

2 Pages

-

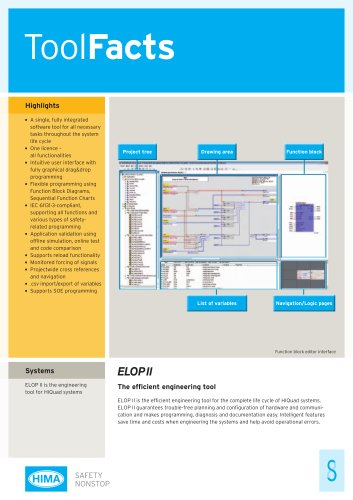

ToolFacts ELOP 2

2 Pages

-

SystemFacts Planar4

2 Pages

-

Brochure HIMatrix general

6 Pages

-

F8627X/F8628X

2 Pages

-

Four new CPUs

2 Pages

-

SystemFacts_HIQuad

2 Pages

-

HIMax®

20 Pages