Catalog excerpts

HIMatrix Safety-Related Controller HIMA Paul Hildebrandt GmbH Industrial Automation

Open the catalog to page 1

All HIMA products mentioned in this manual are protected by the HIMA trade-mark. Unless noted otherwise, this also applies to other manufacturers and their respective products referred to herein. HIMax®, HIMatrix®, SILworX®, XMR® and FlexSILon® are registered trademarks of HIMA Paul Hildebrandt GmbH. All of the instructions and technical specifications in this manual have been written with great care and effective quality assurance measures have been implemented to ensure their validity. For questions, please contact HIMA directly. HIMA appreciates any suggestion on which information should...

Open the catalog to page 2

Structure and Use of this Manual Target Audience Formatting Conventions Safety Notes Operating Tips Intended Use Environmental Requirements ESD Protective Measures Residual Risk Safety Precautions Emergency Information Product Description Safety Function Safety-Related Digital Inputs Reaction in the Event of a Fault Line Control Equipment, Scope of Delivery IP Address and System ID (SRS) Type Label Structure LED Indicators Operating Voltage LED System LEDs Communication LEDs I/O LEDs Communication Connections for Ethernet Communication Network Ports Used for Ethernet Communication Pulsed...

Open the catalog to page 3

Installation and Mounting Connecting the Digital Inputs Surges on Digital Inputs Connection of Digital Pulsed Outputs Cable Plugs Mounting the F1 DI 16 01 in Zone 2 Configuration with SILworX Parameters and Error Codes for the Inputs and Outputs Digital Inputs F1 DI 16 01 Tab: Module Tab: DI 16: DO Channels Tab: DI 16: DI Channels Configuration with ELOP II Factory Configuring the Inputs and Outputs Signals and Error Codes for the Inputs and Outputs Digital Inputs F1 DI 16 01 Pulsed Outputs F1 DI 16 01 Maintenance Measures Loading the Operating System Proof Test Glossary Index of Figures

Open the catalog to page 4

Introduction This manual describes the technical characteristics of the device and its use. It provides information on how to install, start up and configure the module. Structure and Use of this Manual The content of this manual is part of the hardware description of the HIMatrix programmable electronic system. This manual is organized in the following main chapters: Introduction Safety Product Description Start-up Operation Maintenance Decommissioning Transport Disposal HIMatrix remote I/Os are available for the programming tools SILworX and ELOP II Factory. Which...

Open the catalog to page 5

Additionally, the following documents must be taken into account: Name HIMatrix System Manual Compact Systems HIMatrix System Manual Modular System F60 HIMatrix Safety Manual HIMatrix Safety Manual for Railway Applications SILworX Online Help ELOP II Factory Online Help SILworX First Steps ELOP II Factory First Steps Table 2: Content Hardware description of the HIMatrix compact systems Hardware description of the HIMatrix modular system Safety functions of the HIMatrix system Safety functions of the HIMatrix system using the HIMatrix in railway applications Instructions on how to use...

Open the catalog to page 6

Formatting Conventions To ensure improved readability and comprehensibility, the following fonts are used in this document: Bold Italics Courier RUN Chapter 1.2.3 To highlight important parts. Names of buttons, menu functions and tabs that can be clicked and used in the programming tool. For parameters and system variables Literal user inputs Operating state are designated by capitals Cross references are hyperlinks even though they are not particularly marked. When the cursor hovers over a hyperlink, it changes its shape. Click the hyperlink to jump to the corresponding position. Safety...

Open the catalog to page 7

Operating Tips Additional information is structured as presented in the following example: The text corresponding to the additional information is located here. Useful tips and tricks appear as follows: The tip text is located here.

Open the catalog to page 8

Safety All safety information, notes and instructions specified in this document must be strictly observed. The product may only be used if all guidelines and safety instructions are adhered to. This product is operated with SELV or PELV. No imminent risk results from the product itself. The use in Ex-zone is permitted if additional measures are taken. Intended Use HIMatrix components are designed for assembling safety-related controller systems. When using the components in the HIMatrix system, comply with the following general requirements. Environmental Requirements Requirement type...

Open the catalog to page 9

Residual Risk No imminent risk results from a HIMatrix system itself. Residual risk may result from: Faults related to engineering Faults related to the user program Faults related to the wiring Safety Precautions Observe all local safety requirements and use the protective equipment required on site. Emergency Information A HIMatrix system is a part of the safety equipment of a site. If a device or a module fails, the system enters the safe state. In case of emergency, no action that may prevent the HIMatrix systems from operating safely is permitted.

Open the catalog to page 10

Product Description The safety-related F1 DI 16 01 remote I/O is a compact system in a metal housing with 16 digital inputs and 4 pulsed outputs. The remote I/O is available in various model variants for SILworX and ELOP II Factory, see Table 4. Remote I/Os are connected to individual HIMax or HIMatrix controllers via safeethernet. They are used to extend the I/O level, but are not able to run any user program by themselves. The remote I/O is suitable for mounting in Ex-zone 2, see Chapter 4.1.4. The device is TÜV-certified for safety-related applications up to SIL 3 (IEC 61508, IEC 61511...

Open the catalog to page 11

Reaction in the Event of a Fault If the device detects a fault on a digital input, the user program processes a low level in accordance with the de-energized to trip principle. The device activates the FAULT LED. In addition to the channel signal value, the user program must also consider the corresponding error code. The error code allows the user to configure additional fault reactions in the user program. Line Control Line control is used to detect short-circuits or open-circuits and can be configured for the remote I/O, e.g., on EMERGENCY STOP inputs complying with Cat. 4 and PL e in...

Open the catalog to page 12All HIMA catalogs and technical brochures

-

HART COMMUNICATION PROTOCOL

5 Pages

-

HIMax HART SOLUTION

2 Pages

-

HIMatrix CSG

2 Pages

-

HIJunctionBox

2 Pages

-

WIRELESS

2 Pages

-

HICore 1 EVALUATION KITS

2 Pages

-

HIQuad X

2 Pages

-

HIMax

11 Pages

-

HIMax product catalogue

108 Pages

-

Subrack F60

26 Pages

-

IMatrix F30

52 Pages

-

HICore

2 Pages

-

Power supply PS1000

2 Pages

-

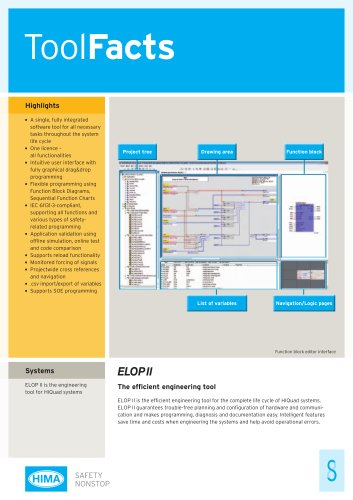

ToolFacts ELOP 2

2 Pages

-

SystemFacts Planar4

2 Pages

-

Brochure HIMatrix general

6 Pages

-

F8627X/F8628X

2 Pages

-

Four new CPUs

2 Pages

-

SystemFacts_HIQuad

2 Pages

-

HIQuad

16 Pages

-

HIMax®

20 Pages