Catalog excerpts

SMART SAFETY. SOLUTION DETAILS HIMA PIPELINE MANAGEMENT CONTROL Detect Pipeline Leaks and React Immediately

Open the catalog to page 1

Material failure, pressure surge, and criminal activity cause a large number of ipeline p i ncidents. Some of them have far-reaching consequences that cost the operator m illions of euros and potentially tarnish their reputation forever. A leak detection system (LDS) allows you to identify such incidents. But to get them under control and prevent costly damages or spills, you also require a safety system. With HIMA, you have two options to solve this challenge. One of them is the FlexSILon PMC Hybrid solution, the world’s first LDS that is integrated straight into an emergency shutdown...

Open the catalog to page 2

Rising Pressure from Every Direction Pipelines are among the safest means of transporting liquids and gases. However, if a problem arises, the impact can be d isastrous – for the environment, for your company’s reputation, and of course for your finances. A leak or puncture in a pipeline can cause costs to skyrocket. The later you identify and resolve the issue, the more it will cost. And then there’s the matter of liability; you or your management may be held accountable for the damage and its far-reaching consequences. Why Pipelines Fail The most common causes of pipeline damage are...

Open the catalog to page 3

Smarter Pipeline Management There are various international standards and legal regulations in place for pipeline integrity. These aim to minimize damage – especially to the environment. One particularly important stipulation is the use of a leak detection system (LDS). However, in many countries, legislation remains unclear and companies are required to follow only those regulations that are deemed “technically feasible”. According to current law, if you conform to these regulations then you may avoid liability for any damage caused. Nevertheless, you will still suffer the financial losses...

Open the catalog to page 4

Minimal Leaks, Faster Fixes HIMA FlexSILon PMC and FlexSILon PMC Hybrid significantly increase the safety and reliability of your pipelines. The solutions help you to comply with all relevant regulations and international standards for pipeline integrity management up to SIL 3. They also prepare you for future requirements. You can adjust and control your pipeline centrally, automate operation, and reduce downtime. Fault-tolerant system architecture minimizes false alarms, which also contributes towards lower OPEX. Furthermore, the HIMax system reduces the risk of technical faults and...

Open the catalog to page 5

For further information, please contact us: HIMA Pipeline Competence Center E-mail: applications@hima.com Or visit us online: © www.hima.com/industries-solutions/pipelines-pmc These companies trust in HIMA pipeline safety solutions: Petrochemical Pipeline Services Praxair Qatar Petroleum RMR Shell Slovnaft TAL Total Vopak Zeeland Refinery Reference number: 96 9000632 0419 V02| © 2019 by HIMA Paul Hildebrandt GmbH | Specifications subject to change without notice.

Open the catalog to page 6All HIMA catalogs and technical brochures

-

HART COMMUNICATION PROTOCOL

5 Pages

-

HIMax HART SOLUTION

2 Pages

-

HIMatrix CSG

2 Pages

-

HIJunctionBox

2 Pages

-

WIRELESS

2 Pages

-

HICore 1 EVALUATION KITS

2 Pages

-

HIQuad X

2 Pages

-

HIMax

11 Pages

-

HIMax product catalogue

108 Pages

-

Subrack F60

26 Pages

-

IMatrix F30

52 Pages

-

HIMatrix F1 DI 16 01

42 Pages

-

HICore

2 Pages

-

Power supply PS1000

2 Pages

-

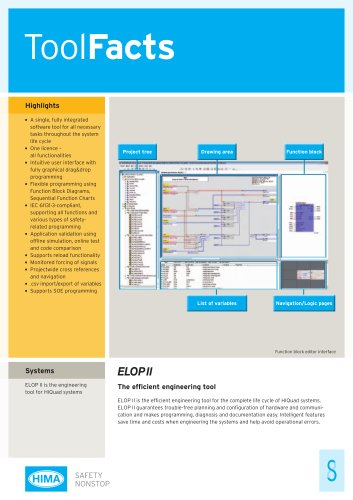

ToolFacts ELOP 2

2 Pages

-

SystemFacts Planar4

2 Pages

-

Brochure HIMatrix general

6 Pages

-

F8627X/F8628X

2 Pages

-

Four new CPUs

2 Pages

-

SystemFacts_HIQuad

2 Pages

-

HIQuad

16 Pages

-

HIMax®

20 Pages