Website:

HG Star Technology

Website:

HG Star Technology

Catalog excerpts

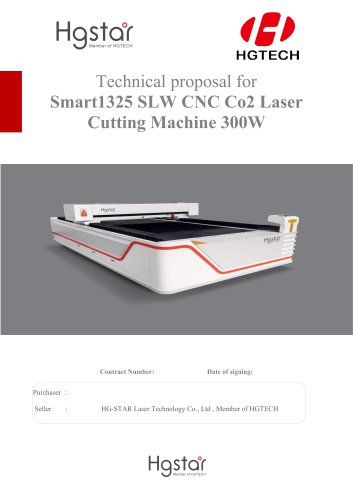

Contract Attachment Technical Proposal

Open the catalog to page 1

1. Laser Tube Cutting Machine Introduction SMART TUBE6015 laser tube cutting machine is manufactured by HGSTAR according to international export standard. This series of equipment is the preferred model for the metal tube processing industry. It has strong cutting capacity, "flying" cutting speed, ultra-high stability, high-quality processing, extremely low operating costs, and super high adaptability. The SMART TUBE6015 laser tube cutting machine can perform high-speed, high-quality laser cutting on round tubes, square tubes, rectangular tubes, and oval tubes. The cutting section has no...

Open the catalog to page 2

2. Technical Specification Parameter Equipment Model Chuck diameter Material type Tube feeding length Maximum blanking length of the tube Maximum single tube weight Laser cutting thickness Carbon steel or round tube, square tube, rectangular tube, oval tube, etc of stainless steel 6000 mm 1500 mm,3500m(Optional) 30Kg/m Carbon steel 1-10mm (thickness and material are related to laser generator) Feeding method XY repeat positioning accuracy A、W axis

Open the catalog to page 3

3. Product Main Configuration List No. Item Bed, beam, Z axis box. Linear Guides: Taiwan TSC, Taiwan Silver Rack: Taiwan APEX The maximum Loading system Artificial feeding loading length 6.0 meters The maximum Loading rack HGSTAR supporting models cutting length 1.5 meters Laser head Raytools standard cutting head Height tracking sensor Servo motor monitor Control system WINDOWS 19-inch screen Laser tube cutting control system

Open the catalog to page 4

Control cabinets, consoles, handheld HGSTAR supporting models Laser source Cooling system HGSTAR supporting models HGSTAR supporting models (No dust removal function)

Open the catalog to page 5

4. laser cutting special function 4.1 CNC Control System (TubePro FSCUT3000) The control system consists of numerical control systems, PLC and control cabinet.etc. HGSTAR adopt the control system develop based on TubePro FSCUT3000, dedicated for laser cutting, FSCUT3000, have modular, openness and unity structure, easy to operate, programming, it’s a kind of visualization and provide a function for all technology innovation platform. With high-speed high-precision closed-loop control system digital servo, and supplemented automation system, FSCUT3000 provides a suitable for complex...

Open the catalog to page 6

4.3 Software generated processing code CAD/CAM software can read 3D graphics that transformed from SolidWorks drawings, and can also draw standard tube cutting graphics in CAD/CAM software. Once the part is imported or drawn, the CAD/CAM software will automatically generate the laser cutting path and the optimal cutting parameters, and automatically set the cutting best solution. The software has automatic optimization statistics. The software can automatically arrange the workpieces under each raw material according to the length of the workpiece and the cut angle combined with the...

Open the catalog to page 7

The clamped tube will be transported to the standby position, waiting for cutting. 4.5 Feeding and Guiding Function System can automatically hold and guide the single tube by the main chuck. During the cutting process, the support frame can lift the tube. Chucks are suitable for different tube clamping. The tube end does not need to be polished, tube end with burrs is automatically cut after feeding. 4.6 Security Protection Function Digital interlocks and safety devices are installed in the laser to ensure that the laser is not turned on for safe operation and maintenance. The perimeter...

Open the catalog to page 8

Protective device, in line with the general technical conditions of GB15760-1995 machine tool safety protection.

Open the catalog to page 9

5. Spare Parts List No. Double Layer Nozzle Single Layer Nozzle Double Layer Nozzle Single Layer Nozzle Double Layer Nozzle Double Layer Nozzle Buckle / Sling Laser Protecting Window Glass Ceramic Ring Isopropanol for optical fiber Laser Protecting Glass wrench/ movable wrench/ flat, cross screwdriver/ wire cutter/ hammer/ plum spanner Peripheral waterway components Equipment lifting assembly

Open the catalog to page 10

Remark 30 days after signing contract, seller is required to provide buyer Basic machine installation drawing and documents with the machine plane locations, 1 basic machine installation drawing and documents, technical requirement of water, electricity and gas source. Operation and Maintenance Manual Electrical schematic diagram Peripheral equipment document Factory quality certification Acceptance Report Consumables List

Open the catalog to page 11

7. Training and After-sales Service "HG-HGSTAR" invested 80 million CNY in the establishment of China's largest and international leading Laser Processing Development Center, which brings together well-known experts, engineers and technicians. All of them are, in close connection with actual business and customer needs, engaged in the development and promotion of laser processing technology. We can provide our customer with expert guidance and process software data service in terms of laser cutting. 7.1 Technical Training The laser processing industry has become a high-tech industry, which...

Open the catalog to page 12

Location Training Carried out simultaneously with the commissioning on customer's site Customer's installation site Participate in the whole process of installation and commissioning. Please refer to the Customer Training Program for other information 7.2 After sales service 1) During the warranty period, after receiving the buyer’s maintenance notice, the seller followed up and responded within 2 hours. If the failure could not be resolved by telephone or email, the seller's technical service personnel would be within 24 hours (up to a maximum of 48 hours). Arrived at the user equipment...

Open the catalog to page 13

8. Equipment Working Conditions and Assistance 8.1 Working Conditions For the long-term stable work of the laser cutting machine for 24 hours, there are the following requirements for water, electricity, gas, working environment, foundation, processing materials, etc.: No. Machine tool Stability of 3-phase power Instability of 3-phase power Grounding <4Ohm Distilled water without minerals AIR pressure should not less than 0.8MPA Working condition requirements Humidity requirements The processing parameters will differ with different materials 2KW laser source need air conditioning room

Open the catalog to page 14All HG Star Technology catalogs and technical brochures

-

CNC Bending Machine

1 Pages

-

Press Brake

1 Pages

-

3D Robot Laser cutting

1 Pages

-

Laser Marking Machine

1 Pages

-

CNC Bending Machine

6 Pages

-

SMART laser cleaning machine

7 Pages

-

Handheld Laser Welder

2 Pages

-

2000W Laser Cutter

19 Pages

-

1000W Laser Cutting Machine

19 Pages

-

Fiber Laser Cutting Machine

18 Pages