Catalog excerpts

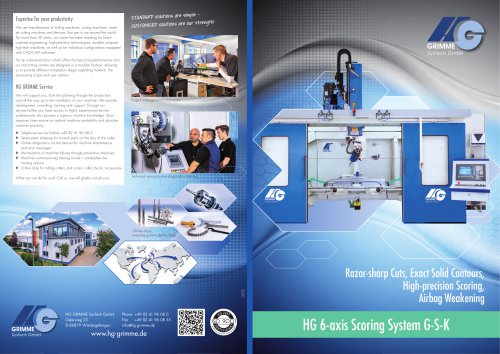

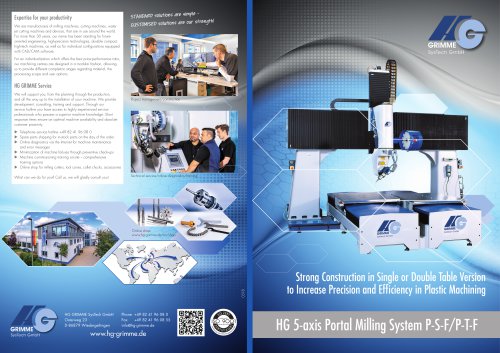

Expertise for your productivity We are manufacturers of milling machines, cutting machines, water jet cutting machines and devices, that are in use around the world. For more than 30 years, our name has been standing for futureoriented engineering, high-precision technologies, durable compact high-tech machines, as well as for individual configurations equipped with CAD/CAM software. ple – Standard so lut ions are sim r st reng th ! CUSTOMISED so lut ions are ou For an individualization which offers the best price-performance ratio, our machining centres are designed in a modular fashion, allowing us to provide different completion stages regarding material, the processing scope and user options. HG GRIMME Service We will support you, from the planning through the production, and all the way up to the installation of your machine. We provide development, consulting, training and support. Through our service hotline you have access to highly experienced service p rofessionals who possess a superior machine knowledge. Short r esponse times nsure an optimal machine availability and bsolute e a customer proximity. Project management/construction u Telephone service hotline +49 82 41 96 08 0 u Spare parts shipping for in-stock parts on the day of the order u Online diagnostics via the Internet for machine maintenance u Minimization of machine failures through preventive check-ups u Machine commissioning training on-site – comprehensive training options u Online shop for milling cutters, tool cones, collet chucks, accessories What can we do for you? Call us, we will gladly consult you! Technical service/online diagnostics/training Online shop: www.hg-grimme.de/en/shop HG Grimme SysTech GmbH Osterweg 23 D -86879 Wiedergeltingen Maximum Production Capacity in a Small Space HG 5-axis-Gantry-Rotary-Table Milling Machine/INCLINED BED

Open the catalog to page 1

Value creation in focus The G-DT-F/SB machining centre with inclined bed and rotary table technology is a further high-tech innovation for the highly efficient and precise milling of work pieces over five axes. The gantry-type construction ensures better dynamics and a long life of all the components. While the machining operation is carried within the interior of the machine the work pieces that have already been machined are ergonomically removed by the machine operator - from the outside at the front - and the new work pieces are put in place. This reduces machine downtime to a minimum....

Open the catalog to page 2