Catalog excerpts

Seperator Moduls in PP + PVC FA12, FA15, FA19 and FA27 20 years ago Hewitech designed the onestep-forming-process – from molten mass to the formed sheet. This modernst technology allows the production of strongest fills (engineered design with stronger edges!) for the lowest price! Forming from flat sheets is history and spend more plastic. The new assembly process by welding for PP and PVC shows strongest connection of the sheets – much stronger than ´mechanical assembly´ of cellular sheets. Open channel structure! Features and Benefits: - Compact moduls with high sedimentation area - Maximum continuous operation temperature at 75°C for PP (55°C for PVC) - Quick and simple installation - Low shipment costs of nested sheets - Very cost effective - Assembly machines (GPS-controlled) available for field assembly - Engineered design of foil-thickness distribution; that means enforced edges of the sheets for ´higher mechanical strength - Hewitech avoid glue and/or toxic chemicals for assembly - Made in Germany - Produced from a UV-protected PP/PVC - Hewitech supports with technical expertise for different applic

Open the catalog to page 1

technical data specific surface channel opening proj. sediment. area hydraul. Diameter material (UV-stabilizied) standard dimensions weight density thickness of foils Further advantages of Hewitech-crossflow film fills: - Hewitech products confirm REACH - all raw materials are listed in the REACH-databank This is the law in Europe - Polypropylene with exceptional chemical resistance and UV-stability - Environmental friendly of PP

Open the catalog to page 2All Hewitech catalogs and technical brochures

-

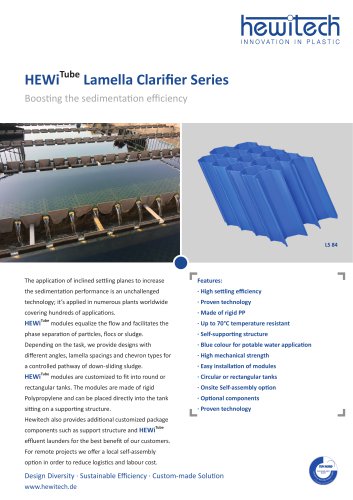

Lamella Clarifi er Series

2 Pages

-

VARIObox Series

2 Pages

-

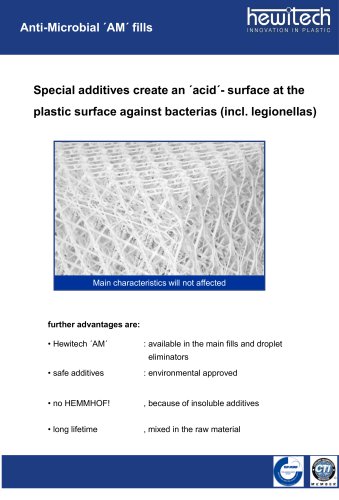

Anti-Microbial

2 Pages

-

VNC 20 TRICKLE GRID

2 Pages

-

DEP156, DEP 177

2 Pages

-

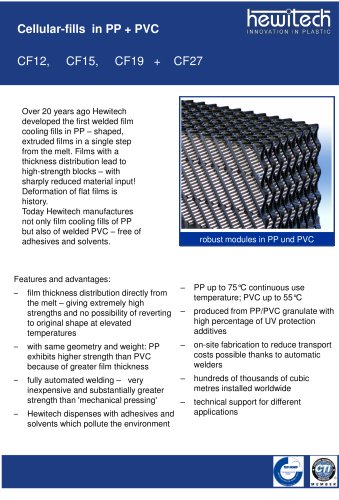

CF12/CF15/CF19/CF27

2 Pages

-

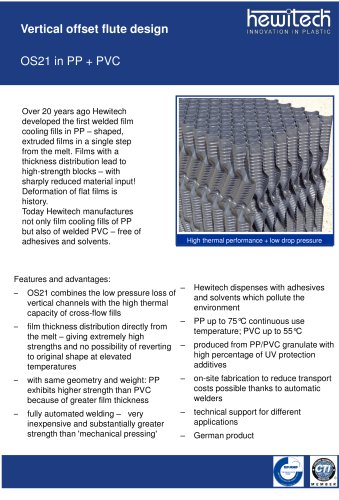

OS21 in PP + PVC

2 Pages

-

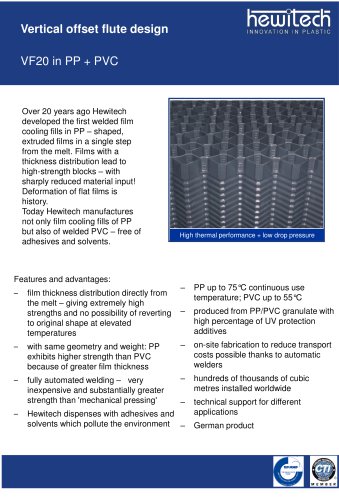

VF20 in PP + PVC

2 Pages

-

Product catalog

2 Pages

-

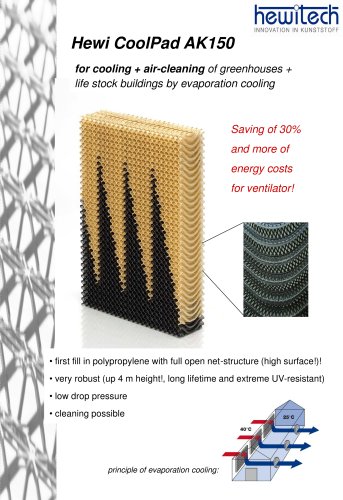

Cool Pad

2 Pages

-

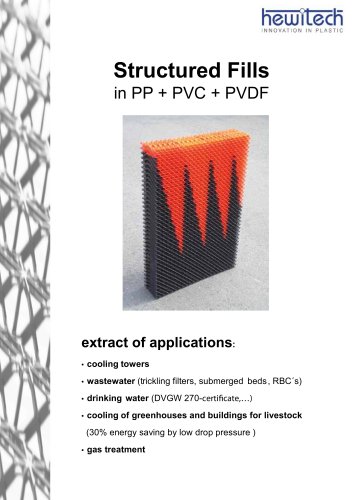

Structured_Fills

2 Pages