Catalog excerpts

BHP-Nozzle, Installation & Service Instructions Safety instructions This symbol indicates explanations about important matters. Failure to read these or false handling could result in injury or damage. Please pay attention to the following safety instructions and precautions Handling • Installation and servicing to be only carried out by suitable personnel according to the installation and service instructions. • Nozzle can become extremely hot. Full face protection and heat resistant gloves must be worn. Damage precaution • Do not drop the nozzle or exert it to unnecessary forces. • Take...

Open the catalog to page 2

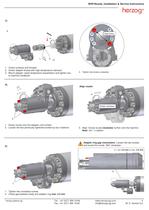

BHP-Nozzle, Installation & Service Instructions Installation instructions Read safety instructions! Legend: with Hand inspection smear with high temperature lubricant temperature equalisation tool Note: Nozzle is delivered pre-assembled. The following instructions are for installation on the machine. For easier handling remove the actuator. Tools required: Hexagonal wrench, allen key, ring spanner, socket wrench, pliers, punch. See chapter Assembly for tool sizes and torques. Installation steps A) - G) A) 2. 1. Loosen and respectively remove heater band screws 2. Take off heater band 1....

Open the catalog to page 3

BHP-Nozzle, Installation & Service Instructions C) 4. über Kreuz 3. 1. 2. 1. Check surfaces and threads 2. Smear adapter thread with high temperature lubricant 3. Mount adapter; await temperature equalisation and tighten acc. to machine handbook D) 4. Tighten two screws crosswise Align nozzle 1. 5. Rotate clockwise 2. 1. Screw nozzle onto the adapter until contact 2. Loosen the two previously tightened screws by four rotations. 3. Align: Screw nozzle clockwise further onto the machine Note: min. ¼ rotation Adapter ring gap nonexistent: Loosen the two screws and screw the nozzle 360°...

Open the catalog to page 4

BHP-Nozzle, Installation & Service Instructions F) 1. Tighten all screws in a crosswise fashion crosswise Torque 1. pass handtight 2. pass 15 Nm 3. pass 22 Nm 4. pass 1. BHP1 25 Nm G) 1b. 1. Mount heater band (1a) and temperature sensor (1b) 2. Attach flexible actuator pipe connections Note: The actuator can be rotated 180° to suit Only for initial operation: Re-tighten screws, tip and heaterband screws with maximum torque. See Initial operation below, torque in chapter Assembly. 1a. 2. Initial operation Read safety instructions! Initial operation: 1. Bring nozzle to operating temperature...

Open the catalog to page 5

BHP-Nozzle, Installation & Service Instructions Service instructions Read safety and cleaning instructions! Assembly Note: Grease all threads with high temperature paste! Attention Actuator service information available seperately in documentation Actuator. For more information see www.herzog-ag.com. Disassembly A) - C) A) 1. 2b. 2c. 2a. Removing the nozzle from the machine: 1. Heat nozzle to operating temperature 2. Remove actuator (2a.), temperature sensor (2b.) and heater band (2c.) B) 5. 1c. 1a. 1. 2. 3. 4. 5. herzog systems ag 1b. 4. 3. 2a. 2b. Remove tip(1a.), screws (1b.), body (1c.)...

Open the catalog to page 6

BHP-Nozzle, Installation & Service Instructions C) Important: The bolt and bolt sleeve may sometimes be difficult to remove. Do not use excessive force on these parts. If you are experiencing problems at this stage of the disassembly please contact Herzog for further assistance. 2. 1. Using a soft punch, strike out carefully 2. Remove sleeve and bolt from above 1. Assembly note: Be careful to align the notch on the bolt sleeve with the positioning stud on the body. Cleaning instructions To clean the nozzle we recommend three methods: 1. Clean the nozzle (without actuator) in a heated state,...

Open the catalog to page 7

BHP-Nozzle, Installation & Service Instructions Assembly Assemble according to the numerical order. Pos. Qty. Grease all threads with high temperature paste! See also chapter: Disassembly. Designation Tool size (torque) BHP1 Metric (Nm) Imperial (lbs/ft) 1 1 Body - - 2 1 Lever - - 2.1 1 Pivot cover - - 2.2 1 Snap ring for bore ø8 mm - - 3 1 Pivot bolt ø10 mm - - 4 1 Bolt BHP - - 5 1 Bolt sleeve - - 6 1 Locking nut SW17 (180) 11/16 (132) 7 1 Bracket / Adapter ring - - 8 8 Screws SW6 (25) 1/4 (18) 9 1 Actuator - - 10 2 Bolt screws SW17 (30) 11/16 (22) 11 1 Bolt ø8 mm - - 12 1 Slip plate - -...

Open the catalog to page 8

BHP-Nozzle, Installation & Service Instructions Parts subject to wear / ordering spare parts Your contact information: Company Street City / Zip Contact Tel. / Fax E-Mail Lasered nozzle identity no.: please insert here Quantity Part (for part name, see chapter Assem bly) Send to: herzog systems ag CH-9230 Flawil / Switzerland Tel. +41 (0) 71 394 19 69 / Fax +41 (0) 71 394 19 60 www.herzog-ag.com / info@herzog-ag.com herzog systems ag Tel. +41 (0)71 394 19 69 Fax. +41 (0)71 394 19 60 www.herzog-ag.co m info@herzog-ag.com 9 M. S. Version 0.2

Open the catalog to page 9All Herzog AG catalogs and technical brochures

-

Type NE

5 Pages