Catalog excerpts

This data sheet interacts with No. 5 Moment Load Carriages HepcoMotion® moment load carriage systems provide extra support and rigidity in applications where high downwards or offset loads are anticipated, typically at work stations. It is also possible to arrange for continuous support of the carriages all around the circuit. Moment load carriages are a variation of the standard fixed centre carriages and are available in all 25 and 44 equivalent sizes. Carriages can be ordered complete with the carriage locking system and with either the fixed or trip latch belt connection facility. This datasheet provides details of the standard moment load carriages, along with information of the alternative design options that are available. Please contact Hepco to discuss application requirements so that a tailored solution can be provided. Moment load carriages are available with two types of work station support, both designed to connect to the track system support beam. Static roller type: with eccentrically adjusted rollers attached to the framework bearing against a fixed skid plate on the underside of the carriage. This reduces the total number of rollers required and therefore the cost of a system with many carriages but few work stations. Moment load carriage (static roller type) Trip Latch Skid plate Track system support beam Sensor mounting bracket Work station support (static roller type) Eccentric rollers adjusted from the front for accessibility. Carriage locking system Dynamic roller type: with eccentrically adjusted rollers attached to the underside of the carriage, bearing on the adjustable height support track. The combination of these adjustable features facilitates set up where accuracy and alignment cannot be guaranteed or where continuous support for the carriage is required all around the circuit. Eccentric roller adjustment from the front for accessibility. Twin roller carriage Single roller carriage Adjustable height support track Track system support beam

Open the catalog to page 1

No. 5 Moment Load Carriages - Static Type The main dimensions of the static type moment load carriages are shown below. For more information or advice to suit a particular application, please contact Hepco’s technical department. Dowel Holes Customer Mounting Holes Part Number Part Number Note: 1. Bearing hole positions are the same as standard FCC carriage plates, please refer to details. 38-39 of the main catalogue for more

Open the catalog to page 2

No. 5 Moment Load Carriages - Static Type The static type moment load carriages are available with the carriage locking system. The main dimensions are shown below. Customer Mounting Holes Part Number Part Number Note: 1. The cylinder is in line with the edge of the beam for the size 44. 2. Bearing hole positions are the same as standard FCC carriage plates, please refer to details. 38-39 of the main catalogue for more

Open the catalog to page 3

No. 5 Moment Load Carriages - Dynamic Type The main dimensions of the dynamic moment load carriages are shown below. For more information or advice to suit a particular application, please contact Hepco’s technical department. A C2 C 4xV Customer Mounting holes Part Number Part Number Note: 1. The length of these components will vary with each application. Please contact Hepco’s technical department for more details. 2. Bearing hole positions are the same as standard FCC carriage plates, please refer to 38-39 of main catalogue for more details.

Open the catalog to page 4

No. 5 Moment Load Carriages - Dynamic Type The dynamic type moment load carriages are also available with the carriage locking system. The main dimensions are shown below. Customer Mounting Holes Part Number Part Number Note: 1. The cylinder is in line with the edge of the beam for the size 44. 2. Bearing hole positions are the same as standard FCC carriage plates, please refer to details. 38-39 of main catalogue for more

Open the catalog to page 5

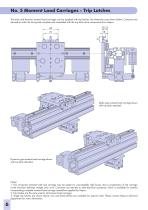

No. 5 Moment Load Carriages - Trip Latches The static and dynamic moment load carriages can be supplied with trip latches, the dimensions are shown below. Customers are advised to order the timing belt complete and assembled with the trip latch drive components from Hepco. 85 Static type moment load carriage shown with trip latch attached. Dynamic type moment load carriage shown with trip latch attached. Notes: 1. The connection between belt and carriage may be subject to unacceptably high forces due to acceleration of the carriage at the transition between straight and curve. Customers are...

Open the catalog to page 6

No. 5 Moment Load Carriages Shown below are some of the variations that can be accommodated within the moment load carriage range. Customers own designs and special size carriages can also be supplied. Please contact Hepco’s technical department for more information or advice to suit a particular application. Dynamic roller type with continuous support around the outside and inside of the circuit. Dynamic roller type with continuous support around the outside of the circuit. Dynamic roller type with an extra wide carriage Dynamic roller type with an extra long carriage Dynamic roller type...

Open the catalog to page 7

No. 5 Moment Load Carriages - Load Capacities L1 HepcoMotion moment load carriage systems provide extra support and rigidity in applications where high direct L1 or offset Ms loads are anticipated. Below is information regarding the load capacity of the standard static and dynamic moment load carriages, this information is based on a system set up with optimal load distribution. Capacities are based on the carriages fitted with Double Row bearings fitted with lubricators, as this will provide the maximum system capacity. Please contact Hepco’s technical department for more information....

Open the catalog to page 8

Selection of Moment Load Carriages Part number details MLC - Moment Load Carriage Choose D Dynamic or S Static CLS - Carriage Locking System Choose from 25 159, 25 255, 25 351, 44 468 or 44 612 T - Trip Latch*1 It is recommended to discuss your application with Hepco’s technical department so a tailored solution can be provided to suit your needs. Below are two examples of complete track systems using moment load carriages and the carriage locking system. These are shown to assist communication, please contact Hepco to discuss in more detail. Track system using dynamic type moment load...

Open the catalog to page 9All HepcoMotion catalogs and technical brochures

-

HLG Hepco Linear Ball Guides

17 Pages

-

SBD Sealed Belt Drive

11 Pages

-

MFS machine fencing system

6 Pages

-

HGS gantry solutions

9 Pages

-

HDS2 Heavy Duty Slide System

27 Pages

-

DTS2 Dynamic Track Systems

8 Pages

-

PRT2 No. 2 Installation Details

10 Pages

-

PRT2 No.8 DTS Components

19 Pages

-

PRT2 No. 11 Mix & Match

3 Pages

-

PRT2 1-Trak

8 Pages

-

Floating Bearings

2 Pages

-

DualVee Wash Down Wheels

2 Pages

-

MCS Catalogue

36 Pages

-

Profiles with Linear Guides

8 Pages

-

ALR Aluminium Rings

4 Pages

-

HTS Drawer Slides Catalogue

40 Pages

-

MHD Catalogue

8 Pages

-

PSD80 No.1 Ballscrew

6 Pages

-

HDRT Heavy Duty Ring and Tracks

13 Pages

-

Uni-Guide – Product Overview

4 Pages

-

ZIMM GSZ & Z Series Screw Jacks

196 Pages

Archived catalogs

-

BSP Ballscrew Premier

9 Pages

-

SL2 Stainless Steel Slide System

15 Pages

-

PRT2 No.6 Bleed Lubrication

8 Pages

-

DualVee Technical Data Guide

12 Pages

-

DualVee Guide Wheels Catalogue

11 Pages

-

MCS – RapiLok

2 Pages

-

ZIMM – Z Series Leaflet

4 Pages