Catalog excerpts

Hepco Gantry Systems

Open the catalog to page 1

TRIED & TESTED SOLUTIONS HepcoMotion’s Heavy Duty Gantry Systems incorporate the highly acclaimed HDS2 Heavy Duty linear motion elements which have been used throughout industry for many years. The separate HDS2 catalogue supplements this catalogue and contains further technical information. It can be consulted for information on standard parts such as Slides, Bearings and Beams. COMPREHENSIVE RANGE The scope of HepcoMotion’s supply has been extended to provide complete stand-alone gantries in most configurations. Motors, controllers, preprogramming and turnkey solutions are all available...

Open the catalog to page 2

Application Examples HepcoMotion.com n Applications shown without motors for clarity. Fully motorised systems n are available with either Servo motors or AC geared motors XZ Gantry with DLS5C Belt Driven Z Axis This dual axis pick and place gantry comprises of a HB33 rack driven X axis and a DLS5C high strength belt driven Z axis please see the DLS5C High Capacity Cantilever datasheet for more information Incorporates high quality cable chain for routing the electrical and control services Both axes fitted with high duty gearboxes on a single dual axis carriage plate Heavy duty cap wipers...

Open the catalog to page 3

Application Examples Bespoke Turn-Key Gantry Solutions HepcoAutomation (&15) specialise in the design of bespoke, user friendly control systems for turnkey gantry applications. In the first instance please contact HepcoMotion for more information. Controlled Environment HepcoAutomation turn key systems provide safe working environments maximising space efficiency. Hepco's robust heavy duty vee slide system used on most axes, is suitable for the harshest of environments as well as being low noise and requiring little maintenance. System Integration HepcoMotion gantries can be integrated with...

Open the catalog to page 4

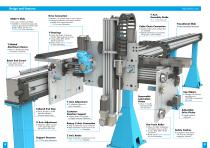

Two sizes: HSS25 and HSS33 Available in commercial (unground), precision (ground) and stainless steel grades. Please see the HDS2 Catalogue for more information n Gearbox, AC geared motor or servo support n Advanced automation and turnkey solutions available from HepcoAutomation. & 15 for more information T-Slotted Aluminium Beams Y Axis Assembly Guide Drive Connection n Heavy duty Hepco V bearings n maintain high positional accuracy n 5 sizes: Ø64, Ø95, Ø120, n Ø128 and Ø150 n Please see the HDS2 Catalogue n for more information Cable Chain Connection n n n n Transitional Slide Standard...

Open the catalog to page 5

Y Axis Alignment n Quick and safe assembly aid n & 11 for more information This ease of assembly location feature allows for the Y axis to be lowered into position quickly and safely Safety Catches n Designed to eliminate the n risk of excess damage in n emergency scenarios Tilt adjustment to accurately position the Y axis assembly in the Z axis plane Tailored End Stop n Shock absorber or buffer n specially selected to n minimise impact forces Cantilever DLS5 The belt driven DLS5C Z axis option is designed for high dynamic applications with low payloads demanding high speeds and...

Open the catalog to page 6

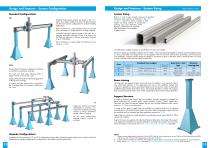

Design and Features - System Configuration Design and Features - System Sizing Standard Configurations System Sizing Standard Hepco gantry systems are based on the HDS2 heavy duty range. Double axes pick and place gantries are the most common configuration for product handling applications. Both axis driven by a high capacity precision rack and pinion mounted on a single dual axis carriage assembly. HGS X, Y and Z axes normally comprise of standard aluminium beam sections as featured in the HDS2 catalogue. Aluminium beams provide a light weight yet strong method of construction reducing...

Open the catalog to page 7

Design Services and CAD Specification Calculator There are many variables that must be taken into account when specifying a gantry system. Hepco's technical department have a custom sizing tool capable of specifying a gantry to suit specific payload, motion profile and duty cycles. Along with Hepco's technical department years of expertise they can provide the optimum gantry configuration. The following application information will be required when specifying a gantry system: n Axis stroke requirements n Payload mass n Payload offsets n Cycle times and distances (or n accelerations and...

Open the catalog to page 8

Linear Guidance and Transmission System Heavy Duty Slide System Aluminium Frame and Machine Construction System Sealed Belt Drive Heavy Duty Track Roller Guidance System Precision Steel and Aluminium Shaft Ring Slides and Track System Heavy Duty Driven Linear System Powerslide-2 Guided Rodless Cylinder Profile Driven Unit Single Edge Slide System Hepco Ball Guides Telescopic Ball Bearing Slides Ball Bushings Linear Bearing System Stainless Steel Based Slide System Linear Transmission and Positioning System Hepco Ball Screws Driven Track System Heavy Duty Ring Slides and Track System...

Open the catalog to page 9All HepcoMotion catalogs and technical brochures

-

HLG Hepco Linear Ball Guides

17 Pages

-

SBD Sealed Belt Drive

11 Pages

-

MFS machine fencing system

6 Pages

-

HDS2 Heavy Duty Slide System

27 Pages

-

DTS2 Dynamic Track Systems

8 Pages

-

PRT2 No. 2 Installation Details

10 Pages

-

PRT2 No.8 DTS Components

19 Pages

-

PRT2 No. 11 Mix & Match

3 Pages

-

PRT2 1-Trak

8 Pages

-

Floating Bearings

2 Pages

-

DualVee Wash Down Wheels

2 Pages

-

MCS Catalogue

36 Pages

-

Profiles with Linear Guides

8 Pages

-

ALR Aluminium Rings

4 Pages

-

HTS Drawer Slides Catalogue

40 Pages

-

MHD Catalogue

8 Pages

-

PSD80 No.1 Ballscrew

6 Pages

-

HDRT Heavy Duty Ring and Tracks

13 Pages

-

Uni-Guide – Product Overview

4 Pages

-

ZIMM GSZ & Z Series Screw Jacks

196 Pages

Archived catalogs

-

BSP Ballscrew Premier

9 Pages

-

SL2 Stainless Steel Slide System

15 Pages

-

PRT2 No.6 Bleed Lubrication

8 Pages

-

DualVee Technical Data Guide

12 Pages

-

DualVee Guide Wheels Catalogue

11 Pages

-

MCS – RapiLok

2 Pages

-

ZIMM – Z Series Leaflet

4 Pages