Catalog excerpts

FISCHERSCOPE® X-RAY Product Line X-Ray Fluorescence Measuring Instruments for the Measurement of Coating Thickness and Material Analysis Coating Thickness Material Analysis Microhardness Material Testing

Open the catalog to page 1

1953 1981 2 X-RAY Product Overview

Open the catalog to page 2

Knowledge, Competence and Experience you can rely on Since 1953, FISCHER has developed and produced innovative measuring technologies for the measure- ment of coating thickness, materials analysis, micro- hardness measurement and materials testing. Meas- uring technology from FISCHER is currently employed all around the world - wherever accuracy, precision As one of the pioneers in using X-ray fluorescence for industrial measurement, FISCHER quickly recognised the tremendous potential of this method for measur- ing coating thickness and began developing and manufacturing industrial-strength...

Open the catalog to page 3

X-ray fluorescence analysis (XRFA) The Energy Dispersive X-Ray Fluorescence Analysis (ED-XRFA) is a method for measuring the thickness of coatings and for analysing materials. It can be used for the qualitative and quantitative determination of the elemental composition of a material sample as well as for measuring coatings and coating systems. In both laboratory and industrial environments, this method is now well established and can be readily utilised with modern equipment. ED-XRFA is a very universal method offering some outstanding advantages. It covers virtually all techni- cally...

Open the catalog to page 4

X-ray fluorescence analysis has its basis in the phe- nomenon that, when atoms in a material sample are excited by the primary X-radiation, electrons from the innermost shells are released; the resultant vacancies are then filled by electrons from the outer shells. During these transitions, fluorescent radiation is gen- erated that is characteristic for each element. This is read by the detector and provides information on the Because ED-XRFA is capable of determining the com- position of materials and measuring thin coatings and coating systems, there is a wide variety of appli- cations...

Open the catalog to page 5

FISCHERSCOPE® X-RAY Measurement Systems X-ray tube Primary filter Measurement result Proportional counter tube X-RAY Product Overview

Open the catalog to page 6

It takes ingenuity and solid, continuous development to create robust and high-precision X-ray measuring instruments that work reliably in both laboratory and everyday industrial settings. We at FISCHER have committed ourselves passionately to this mission, which is reflected in the wide variety of FISCHER- SCOPE X-RAY instruments we produce. For example, systems with X-ray tubes that radiate from bottom to top are ideal for quick and simple measurements on mass-produced parts, but for speci- mens like silicon wafers, which must be measured without contact, the correct choice is an...

Open the catalog to page 7

FISCHERSCOPE® X-RAY Measurement Systems Shutter The shutter is located directly in the beam path and is opened only for the duration of the measurement. In its closed state, it prevents the primary radiation from entering the measuring chamber. Monitored by the safety system, it opens only when the housing is completely closed, eliminating the risk of radiation for the operator. Video camera FISCHERSCOPE X-RAY measurement systems are equipped with a high-magnification camera optics that enables the setting of specimen measurement locations with minute accuracy. Because the software depicts...

Open the catalog to page 8

Sample support and stages Whether for quickly placing and measuring a sample or for performing automatic measurements of com- plex components, FISCHERSCOPE X-RAY measure- ment systems are furnished with appropriate sample supports, ranging from simple, plane probe supports or manually operable XY-stages through to high-preci- sion, programmable XY-stages. Positioning aids Simple and fast sample positioning saves time and money. For this reason, all instruments with an XY- stage feature a laser pointer as a positioning aid, which greatly streamlines the localisation of the mea- surement...

Open the catalog to page 9

WinFTM® Software Here, FISCHER leads the way, implementing in Win- FTM numerically effective algorithms that are based on a lifelike physical model. For this reason, all mea- surements can also be carried out standard-free. But WinFTM is more. It is also the command centre for user-friendly operation and optimal employment of the FISCHERSCOPE X-RAY measuring instruments, not only in the laboratory but also in daily industrial From simple coating thickness measurements in the electroplating industry, such as zinc on iron, to bath analyses, complex multi-coating applications, sophis- ticated...

Open the catalog to page 10

For this reason, FISCHER has designed the WinFTM Software such that no particular training is required for routine measurement operations. Based on the well-known Windows standard, its intuitive user interface and predefined, automated processes and command buttons make the job easy. All functions are quickly accessible and displayed only if they are actually needed, ensuring that the screen is always clearly arranged and uncluttered. Solid physical foundation WinFTM employs an algorithm based on fundamen- tal parameters in order to determine composition of alloys, as well as thickness and...

Open the catalog to page 11

WinFTM® Software Substrate Material Recognition For certain coating thickness measurements, WinFTM can automatically analyse the substrate material as well. This not only eliminates the need for normali- sation when taking measurements on different mate- rials, it also increases the reliability of the results because the coating thickness is correctly measured despite eventual fluctuations in substrate material Using the COM function, unknown samples can be assigned automatically to a predefined material class. These classes may be different kinds of materi- als, e.g. different alloys,...

Open the catalog to page 12

Furthermore, WinFTM presents the measurements alternatively as a distribution (histogram, probability chart) or in a Statistical Process Chart (SPC). Capa- bility indices Cp and Cpk are calculated for the speci- fied tolerances. Export Measurement Results and Print Forms Single readings and block mean values, along with their measurement uncertainties, characteristic statis- tical values and any additional data relevant to the measurement, can be exported into files and evaluat- ed using, for example, quality management systems. The integrated report generator produces individual result...

Open the catalog to page 13All HELMUT FISCHER GMBH - INSTITUT FÜR ELEKTRONIK UND catalogs and technical brochures

-

MMS® Inspection

8 Pages

-

MMS® Inspection DFT

6 Pages

-

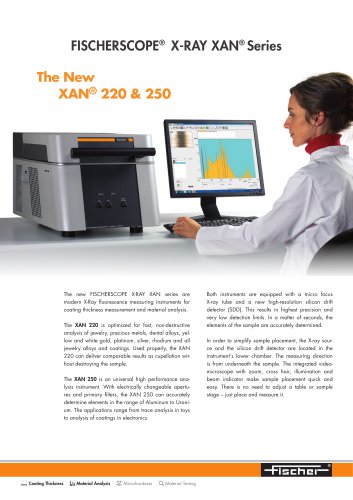

FISCHERSCOPE ® X-RAY SERIES

48 Pages

-

PRECIOUS METALS AND JEWELERY

4 Pages

-

Automated Measurement Solutions

28 Pages

-

FISCHERSCOPE® X-RAY XAN® 500

4 Pages

-

FISCHERSCOPE® ST200

4 Pages

-

MMS-PC2

16 Pages

-

SIGMASCOPE GOLD

4 Pages

-

XAN250-252

4 Pages

-

XAN220-222

4 Pages

-

Inline Measuring Systems

8 Pages

-

XAN Series

36 Pages

-

GOLDSCOPE Series

8 Pages

-

PMP10 Duplex

4 Pages

-

FMP100/150

8 Pages

-

MP0/MP0R Series

8 Pages

-

Brochure DUALSCOPE® FMP100

8 Pages

-

FISCHERSCOPE X-RAY XDV-SDD

2 Pages

-

FISCHERSCOPE X-RAY XDAL

2 Pages

-

PHASCOPE PMP10 DUPLEX

4 Pages

-

Probe catalogue

12 Pages

-

FISCHERSCOPE MMS PC2

16 Pages

-

FISCHER Product Overview

24 Pages