Catalog excerpts

ABOUT�US "Heldors" specializes in laboratory and industrial thermal equipment. The company is manufacturing a wide range of electric furnaces, drying ovens, incubators for various thermal processes. All the products are handmade, which makes the quality level incredibly high. We believe that the “world consists of small things”, therefore all the products are developed with passion and every part is made in consideration to the last detail. Heldors team consists of strong R&D personal, therefore the company not only offers standard products, but is also able to customize the products...

Open the catalog to page 2

Customized�industrial�gas�fired�ovens�for�burn� out�of�electric�motors,�powder�paints System alowes to to burn out electric motors and afterburn the smokes. System is unique because the main chamber is heated by using afterburned smokes temerature. This alowes to reuse the heat and reduces enrgy consumption. Main chamber volume: 3000…10.000l; Incinerator; Heat exchanger (unique one burner system, which allows to use hot smokes); EN 1539; Chamber material: stainless steel; Zinc coated and powder painted external casing; Modulating gas burner; Forced smoke extraction; Electromechanical door;...

Open the catalog to page 3

The space in production is expensive, therefore bell type solutions one of the best way to solve such issues. Combinated systems (heating/ cooling) allow fast charge moving between the operations. Compact design; Main chamber volume (second floor): 1000…10.000l; Forced air cooling chamber (ground floor); Temperature: 260…1300 °C; Zone control; Automatic process; Chamber material: stainless steel; Stainless steel frame and casing; Double door from two sides

Open the catalog to page 4

Customized�conveyor�furnaces Contynuous production requies fast cycle operations. Belt type or roller heart continuos furnaces one of the most eficiant solutitions for such aplications. Furnaces is used for heat treating products where high volume production and low cost are favored. Design according the process; Temperature: 260…1100 °C; Belt/rollers; Zone control; Natural or forced air circulation; Automatic process; Smart conveyour placement system; Samples colection; Adjustable speed; Lazer sensors

Open the catalog to page 5

Heldors offers warious quencing systems in air, water, oil. Charge can be queched in air or inertial gas aplications. System can be manual or automatic. Design according the process Temperature: 900…1000 °C Air circulation Quenching tank Fast door opening Customized loding Double water shaking system

Open the catalog to page 6

Heldors offer gas fired or electric heated dewaxing furnaces with liquid wax collection and smoke afterburning. Furnaces is designed for work in agresive atmosphere. Design according the process Gas fired system Lightweight insulation (low inertia) Incinerator Temperature: 800 °C Camber size: 1000…10.000l; Bogie hearth Liquid wax

Open the catalog to page 7

Professional chamber furnaces Heldors ICF line is made for hardening, cementation and other thermal treatment processes of various materials in temperature range from 50⁰C to 1300⁰C in air conditions or with inertial gas (optional). Counterweight helps to open and close the doors very fast and easy. Strong and reliable frame construction; Powder painted casing; Free radiation wire heating elements on tubes; Heating from three sides (two sides and bottom); Ceramic bottom plate (for models up to 40 liters); SiC bottom plate (for models bigger than 70 liters); Downward doors with counterweight...

Open the catalog to page 8

Professional chamber ovens Heldors ICO line is made for tempering, annealing, ageing, preheating, drying, age hardening and other thermal treatment processes of various materials in temperature range from 50⁰C to 860⁰C in air conditions or with inertial gas (optional). Ovens goes with vertical or horizontal air circulation. BASIC�MODEL Strong and reliable frame construction Powder painted casing Chamber material: 260⁰C models: mild steel painted with heat resistant paints (Zinc coated mild steel or stainless steel optional) 360⁰C models: mild steel painted with heat resistant paints...

Open the catalog to page 10

Professional double door chamber furnaces is very good choice when is needed air circulation furnace up to 860⁰C and high temperature up to 1200⁰C. System is compact and can be used as two in one solution for various proceses in air conditions (inertial gas connection and semo tight chamber could be ordered as an option). BASIC�MODEL Strong and reliable frame construction Zinc coated and powder painted casing Free radiation wire heating elements on tubes Heating from three sides (two sides and bottom) SiC bottom plate Doors with air circulation fan opens to the left hand side (for...

Open the catalog to page 14

Considerings customers requiests Heldors designed special Table Top Furnaces. Compact design and strong chambers makes these furnaces very convenient for small workshops. BASIC�MODEL Zinc coated and powder painted casing Free radiation wire heating elements on tubes Heating from three sides (two sides and bottom) Ceramic bottom plate Doors with counterweight Doors opens down Chamber made from bricks Door made from pressed fiber modules (shock resistant) Reliable door sealing with fiber Ceiling is made from fiber boards Hot surfaces around the arc made from stainless steel Solid state relay...

Open the catalog to page 15

Professional bogie hearth furnaces Heldors IWF is developed for heavy loads. Line is made for hardening, cementation and other thermal treatment processes of various materials in temperature range from 50⁰C to 1300⁰C in air conditions or with inertial gas (optional). Strong and reliable frame construction Powder painted casing Manually operated bogie-hearth (electromechanically optional) Rails (on the floor) in front of the furnace Free radiation wire heating elements on tubes SiC bottom plates Door opens to the side Chamber front arc and bottom made from bricks Lightweight insulation (low...

Open the catalog to page 16

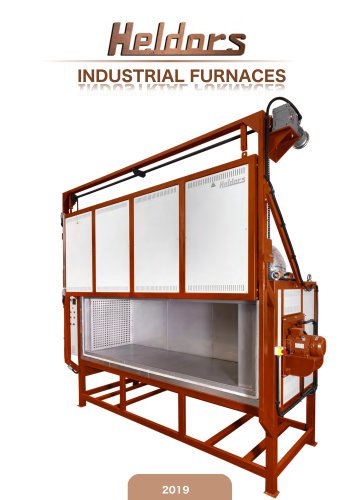

Professional bogie hearth furnaces Heldors IWF with forced air circulation is developed for heavy loads. Line is made for tempering, annealing, aging, normalizing, preheating, vulcanization, polymerizations, drying and other thermal treatment processes of various materials in temperature range from 50⁰C to 860⁰C in air conditions or with inertial gas (optional). Strong and reliable frame construction Powder painted casing Manually operated bogie-hearth (electromechanically BASIC�MODEL optional) Rails (on the floor) in front of the furnace Chamber material: 260⁰C models: mild steel painted...

Open the catalog to page 18