Website:

HEINRICH GEORG GmbH

Website:

HEINRICH GEORG GmbH

Catalog excerpts

Convincing with outstanding solutions: Leading technology for transformer production. transformer division

Open the catalog to page 1

‘With a passion for technology we at GEORG have been developing inspirational solutions for generations which is being driven by both our success and our customer confidence.’ Mark Georg CEO & Chairman of the Boar

Open the catalog to page 3

That is GEORG. ‘future-driven knowledge’ – GEORG welcomes you where the future starts. Our Company history from its birth to date is a signpost for a strong future. Founded in 1948 as a visionary one-man business, GEORG today is a successful family-owned company and a global player. We link the experiences of several generations to meet the technical challenges and to create new market impulses. What we have in common is our belief in entrepreneurial sustainability. Our employees with their passion for technology, as well as our common responsibility for what shall be preserved, are always...

Open the catalog to page 5

machine tool division In close cooperation with our customers we develop and produce extraordinary tooling machines that perfectly fit any requirement. Creativity and superior knowledge lead to innovative and technically leading turnkey solutions for maximum long-term manufacturing results. finishing lines division Our finishing lines have been designed for sustainable efficiency: with extremely short set-up times, easy operation with minimum personnel and perfect, processcontrolled operations. Using our leading technological solutions we ensure our customers success in the future....

Open the catalog to page 6

transformer division With proactive strong partnerships, using our expandable modular machine concepts we design state of the art process lines and equipment for transformer production. We are the world market leader because our customers rely on our technology. The company divisions – grown by experience With the development of pioneering technologies we not only rely on years of experience, but inspiration to improve our processes by exploring new directions in different fields to deliver creative solutions.

Open the catalog to page 7

‘Demanding partners are as important as innovative technology. That is why our customers have confidence in us – and we in them.’ Bernd Peter Schmidt Managing Director transformer divis

Open the catalog to page 8

GEORG transformer lines Reliable solutions Proven in transformer plants and service centers all over the world GEORG transformer lamination cutting lines are known for their reliability, accuracy and productivity. We develop machines fitting to the individual customer’s needs, with fixed shears or swing shear configuration, whether with simpler stacking systems or fully automatic E-stackers. Our experience in transformer production lines also leads us to develop perfect slitting lines for grain oriented electrical steel. With our wide range of core assembly tables, we supply production...

Open the catalog to page 9

Our customers GEORG serves a wide range of customers Small and medium size companies These customers need a reliable partner, which supports them during the complete life time cycle of their machine. Many of these companies – family owned, such as the GEORG company – successfully operate GEORG machines for more than 30 years. The partnership between these customers and GEORG is often more than a supplier-customer-relation. With our reliable standardised ecoline range, we offer affordable solutions in core cutting even for very small transformer manufacturers

Open the catalog to page 10

Multinational corporations On the other hand, many of our customers are big multinational corporations. The various needs of their individual plants all around the world are discussed and lead to new technically superior solutions by working in close cooperation. Innovative technology and strong partnerships are necessary for being prepared for the future – and this is exactly what we stand for.

Open the catalog to page 11

Strong arguments GEORG. This means passion for technology but as well: > GEORG production lines for the transformer industry ‘Made in Germany’ from the mechanical to the electrical system – for decades. > Facing the future with our independent research & development department: for superior solutions for your benefit. > World-wide availability: on site with GEORG specialists from our national and international subsidiaries and agencies, by remote-access or via our Service-Hotline. > Training to learn all about your GEORG machine in our customer centre > Modernization of your existing lines...

Open the catalog to page 13

Product range GEORG precisionslit GEORG precisioncut GEORG precisionstack Slitting lines Stacking tables

Open the catalog to page 14

GEORG ultracorrugation Corrugated fin wall production lines Special core production lines Individual solutions

Open the catalog to page 15

GEORG precisionslit Slitting lines The most essential parameters > > > > > > Coil weights of 6 or up to 12 tonnes Strip widths up to 1,250 mm Thickness ranges between 0.18 and 0.65 mm or up to 1.0 mm Strip material speeds of 140 m/min or up to 200 m/min Low burr slitting process Low camber slitting process Accurate wound coils on recoiler mandrel Slitting shear

Open the catalog to page 16

Advantages for your production plant > > > > Slitting line with movable tension unit High level of cutting accuracy by means of high precision shear Low burr and low camber slitting process due to optimized shear design Convenient strip infeeding with movable tension unit By various pneumatic systems the tension can be adjusted individually resulting in high winding accuracy. GEORG precisionslit 1200 slitting line

Open the catalog to page 17

GEORG precisioncut TBA core lamination cutting lines Sizes from TBA300 up to TBA1200 >> >> >> >> >> >> >> Fixed shear lines Swing shear lines Hole punch units V-notch units Slot punch units Tip cutting shears Various decoiler solutions Notching part Roof stacker Two level pneumatic stop stacker Two level servo belt stacker In line bridge type stacker Fully automatic E stacker Swing Shear at GEORG precisioncut TBA1200 S

Open the catalog to page 18

The most essential parameters >> >> > >> Depending on machine type for strip widths up to 1,250 mm Depending on machine for sheet lengths up to 6,000 mm Thickness ranges between 0.18 and 0.35 mm or up to 0.5 mm Output up to 190 sheets per minute Advantages for your production plant >> >> >> >> >> >> High output / throughput by minimising tool times and high production speeds Exact sheet lengths and low burr cutting Expensive scrap minimised Electric operated shears and notches minimize maintenance work Wide range of stacking systems Highest reliability in core production STA/B stacker for...

Open the catalog to page 19All HEINRICH GEORG GmbH catalogs and technical brochures

-

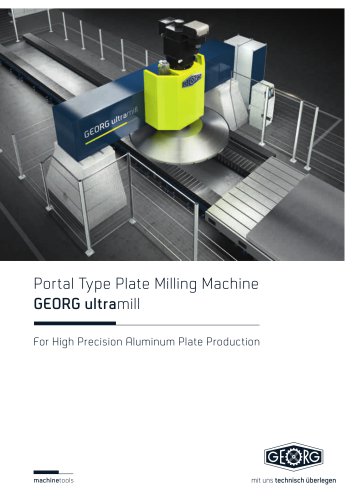

Datasheet GEORG ultramill

2 Pages

-

Advanced Aluminum Technology

5 Pages

-

GEORG precisioncut TBA400

2 Pages

-

TBA600 ecoline

2 Pages

-

TBA400 ecoline L

2 Pages

-

TBA300 & TBA400 robotline

2 Pages

-

Slitting Line

2 Pages

-

TBA400 ecoline L

2 Pages

-

TBA300 miniline

2 Pages

-

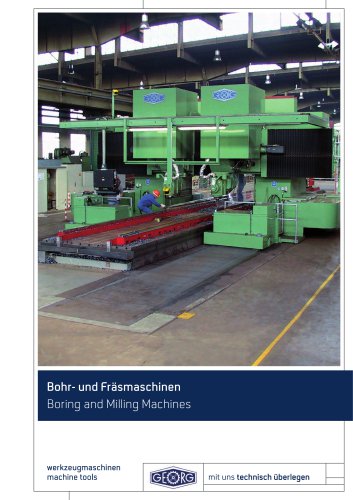

machine tool division

36 Pages

-

finishing lines division

32 Pages

-

GEORG precisioncut 300 wound

2 Pages

-

KLT ? 10-30 t

2 Pages

-

KLT & KMT ? 1-5 t

2 Pages

-

TBA1200

2 Pages

-

TBA800

2 Pages

-

TBA400 & TBA600 ecoline

8 Pages

-

TBA400 ecoline

2 Pages

-

Grinding Machines

2 Pages