Website:

Heidelberger Druckmaschinen AG

Website:

Heidelberger Druckmaschinen AG

Catalog excerpts

The peak performance class.

Open the catalog to page 1

A partnership that pays off. Heidelberger Druckmaschinen. The key to your success lies in the coordinated interaction of people, processes, materials, and machines. We are a reliable and competent partner for all your printing needs. Our user-friendly systems, customized products, and innovative services deliver maximum production quality, make controlling complex processes easier, and help you to avoid errors – all along your production chain. The result: Efficiency at the touch of a button. We call it Simply Smart. The advantage for you: simpler and more productive processes thanks to an...

Open the catalog to page 2

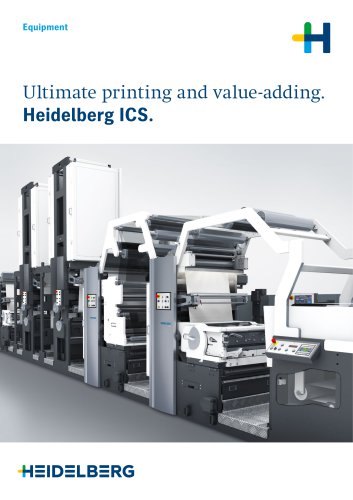

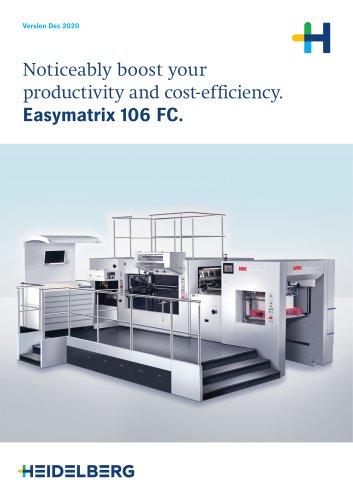

Equipment Rely on future-proof printing and further processing by combining digital and offset printing. Our portfolio for printing machines ranges from cutting-edge digital technologies and offset printing machines attractively equipped as standard to individually configured special machines for maximum productivity and every possible print application. From prepress to postpress – we enable the entire printing process for commercial and packaging printing. Our machines are networked through the Prinect workworkflow and can thus exchange production data: for the sake of optimum processes...

Open the catalog to page 3

Technological advantage. Speedmaster XL 75. Our Speedmaster® XL 75 is the result of development geared entirely towards our customers’ needs. This future oriented press in 50 × 70 cm (19.69 × 27.56 in) format delivers top efficiency, maximum productivity, and total ease of operation – for the greatest possible success without any compromises. The Speedmaster XL 75 offers you extensive configuration options for the most demanding requirements in commercial, label, and packaging printing. The result is a customized press, designed for your success in the market. Get the jump on industrial...

Open the catalog to page 5

The high-performance control station. Prinect Press Center XL 2. The Prinect Press Center XL 2 sets new standards in operating philosophy. Take the crucial step towards fully automated job changing with Push to Stop and navigate through complex makeready processes with Intellistart 2. Productivity made easy User-friendly operation is about more than a pleasant working experience. It is also an important prerequisite for maximum efficiency – print job by print job. The Prinect Press Center® XL 2 offers you this user-friendly operation thanks to outstanding ergonomics and intuitive operation....

Open the catalog to page 6

Perfect data and color management with Prinect The Prinect Press Center XL 2 integrates your printing press into the Prinect® print shop workflow. Current job data is automatically uploaded. At the same time, processes can be initiated from the control station. You benefit from excellent data management, current production data, and informative reports. Prinect also offers you various color measuring systems for optimal, reproducible color stability. Two further spectrophotometric color measuring systems are available as an alternative to the Prinect Inpress Control 2 inline color measuring...

Open the catalog to page 7

Leader in the printing process. 15 clear benefits*. Makeready for fully automatic, staggered plate changes on a Speedmaster XL 75-5+L with AutoPlate Pro. Protective liner instead of bare metal – cleaning the ink fountain takes just 1 minute instead of 5 – 10 minutes. No more flying blind – with Prinect Inpress Control 2, the first measuring results are delivered after less than 30 sheets and the run is ready to start in under 1 minute. 34 seconds to wash rubber blankets with the fastest washup program. 90% 21 % energy saving with round-nozzle dryers compared with previous technology....

Open the catalog to page 8

Outstanding characteristics. The facts at a glance. Equipment: • High-performance control station Prinect Press Center XL 2 with innovative, process-oriented operator guidance system Intellistart 2. • Intellistart 2, the patented process- and job-oriented assistance system for efficient job preparation and automatic generation of time-optimized job change programs. Complete overview of all job parameters and transparency of the workflows. • Highly automated Preset Plus feeder for faster setup, greater precision, higher continuous production speeds, and reliable, continuous production. •...

Open the catalog to page 9

The Speedmaster XL 75 is setting standards in this format class. The innovative technology used in the press offers you the highest level of automation, the greatest ease of operation, the shortest makeready times, and stable processes. Custom configured for your requirements, the smooth interaction of all the components ensures peak performance – superlative quality and economy for your success. Highlights • The Anicolor® 2 inking unit provides flexible inking and constant color stability combined with the shortest makeready times and minimal startup waste. • Fully automated makeready...

Open the catalog to page 10

Perfect piles thanks to the Preset Plus delivery ensure smooth postpress operations. The coating unit permits outstanding coating and drying results, even at the highest speeds. The inking and damping unit permits stable coloring throughout the entire run. Speedmaster XL 75-8-P+LYYL with FoilStar. The press shown is a sample configuration. Some of the equipment features mentioned are optional. Feeder The Preset Plus feeder looks after all the relevant format and air settings for the shortest makeready times and steady sheet travel. Cold foil module The FoilStar® system offers inline...

Open the catalog to page 11

The perfect sheet travel ensures peak performance from the feeder to the delivery. Fully automatic plate changes with AutoPlate Pro or AutoPlate XL. Fully automatic switchover of the Preset Plus feeder ensures the fastest material changes. Color and register measurement and control system Prinect Inpress Control 2 spectrophotometrically measures and controls the color inline during production. The register is checked at the same time and readjusted if necessary. Coating unit The coating unit with chambered blade system and CoatingStar® with pulsation-free coating delivery and integrated...

Open the catalog to page 12All Heidelberger Druckmaschinen AG catalogs and technical brochures

-

Diana Eye 42/55.

8 Pages

-

Speedmaster CX 104

13 Pages

-

Speedmaster SX 102.

20 Pages

-

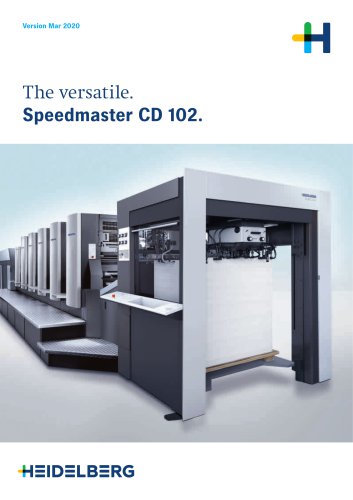

Speedmaster CD 102.

8 Pages

-

Speedmaster CS 92.

8 Pages

-

Speedmaster CX 75.

20 Pages

-

Versafire EM.

2 Pages

-

Gallus ECS 430

12 Pages

-

Gallus ECS 340

12 Pages

-

Versafire EP.

2 Pages

-

LabelSystem SC-20

1 Pages

-

CuttingSystem 120

1 Pages

-

Prinect Production Manager

2 Pages

-

Prinect Color Toolbox

2 Pages

-

Comfortable Production

2 Pages

-

Heidelberg CCS

7 Pages

-

Speedmaster XL 145 and XL 162

20 Pages

-

Stahlfolder TH/KH

11 Pages

-

Versafire EV

2 Pages