Website:

Heidelberger Druckmaschinen AG

Website:

Heidelberger Druckmaschinen AG

Catalog excerpts

gaiius A Heidelberg Group Company

Open the catalog to page 1

Maximum versatility for label printing. The Gallus RCS 430 stands out thanks to its extensive automation and the maximum flexibility it offers when choosing printing methods. This successful machine system performs impressively across the board thanks to its unique modular design. Label printers around the world trust in the high productivity of Gallus RCS machine systems that help them set quality benchmarks in label printing. What’s more, Gallus has achieved another technical milestone with the RCS 430, thanks to its cutting-edge units for UV offset printing. As a modular inline press...

Open the catalog to page 2

Exceptional productivity and flexibility for the production of complex labels.

Open the catalog to page 3

Maximum process flexibility The Gallus RCS 430 harnesses unrivalled application and process flexibility for label printers. The press can handle any substrate with ease – from extremely thin monofoils that are just a few micrometres thick to tube laminates up to 450 micrometres. Fast, straightforward and without separating the web The Gallus RCS 430 supports six printing processes and is thus redefining the future of label printing. Offset printing, flexographic printing, screen printing and hot foil embossing can be easily integrated at any position in the press in a matter of just a few...

Open the catalog to page 4

Maximum flexibility and quality as regards processes and substrates. A sturdy top rail makes mounting and moving press assemblies extremely easy. Dramatic reduction in setup and changeover times thanks to automation and direct drive technology.

Open the catalog to page 5

The benchmark for operational efficiency The consistent platform concept, modular design and high degree of automation ensure cost-effective and eco-efficient production to the highest standards in printing quality. When working on repeat orders, the job data memory can be used to call up machine setting data from the main memory as required. Cutting-edge control technology The new generation of Gallus machine systems features the latest control technology and unlocks potential synergies for label printers that are using a range of Gallus machine systems – as you would expect from a...

Open the catalog to page 6

Automation on top By using Flying Imprint for flexographic printing, operators can change texts and motifs without interrupting production. And, thanks to optimum end-to-end automation, the Gallus RCS 430 supports extremely short job changeover and setup times with minimal waste. The format variability of the Gallus RCS 430 also ensures complete machine flexibility when it comes to printing methods, substrates and job structures. Automation in offset printing The inking and wetting units on the Gallus RCS 430 are driven separately, which means the press can achieve the necessary ink/water...

Open the catalog to page 7

Leading quality in UV offset printing Using the Gallus RCS 430, label printers can achieve print results to the highest possible quality standard while maintaining the best possible performance in terms of output and cost-efficiency. The robust design, state-of-the-art servo drive technology and intelligent user interface ensure optimum print quality. Thanks to its high degree of automation, the Gallus RCS 430 achieves offset printing results in a quality that matches that of sheetfed offset. Highly reproducible quality Equipped with the latest, configurable servo direct drives, the Gallus...

Open the catalog to page 8

Unique offset inking and wetting unit The inking and wetting unit of the Gallus RCS 430 incorporates 21 rollers that ensure consistent, outstanding and reproducible printing quality, very short setup times and reduced waste. As in modern sheetfed offset presses, the wetting solution is applied via a separate forme damping-roller. Three inking rollers transfer the ink to the plate cylinder. A bridge roller connects or disconnects the wetting unit to/from the inking unit. It can be applied for rapid inking-up or washing and for printing without the wetting unit (e.g. varnishing of solids)....

Open the catalog to page 9

Technical specifications Substrates PS materials Monofoil materials Paper Cardboard Tube laminates Machine System Gallus RCS 430 Machine specifications Mechanical machine speed max.160 m/min525 ft/min Web width max.435 mm17 1/8" Web width min. 160 mm 6 3/8" Printing and processing width max.430 mm17" Flexographic, screen and cold foil printing plus hot foil embossing Format range304.8 - 635.0 mm12" - 25" Format lenght increment standard3.175 mm1/8" Format lenght increment optionalcontinuouscontinuous Number of print operations max. 14 Rotary processing Format range 304.8 - 635.0 mm 12" -...

Open the catalog to page 10

Gallus Customer Service – completely individually Gallus Original Parts & Consumables Gallus Rotascreen – simple integration for optimum results Technology Support Innovation gives our customers a crucial competitive edge. The experienced Gallus team provides them with optimum coordination of print and finishing options, application tests and professional consulting and support for all operational processes. A chain is only ever as strong as its weakest link. An insignificant fault can have a huge impact – if a sensor fails, for example, this can shut down an entire press or reduce print...

Open the catalog to page 11

Gallus and Screeny are registered trademarks of Gallus Ferd. Rüesch AG in the U.S., EU and other countries. All other trademarks are property of their respective owners. Pantone is a registered trademark of Pantone Inc. All other trademarks are property of their respective owners. This publication is protected by copyright. Subject to technical modifications and other changes. The contents of this brochure have been prepared with great care. No warranty or liability is accepted for the correctness, completeness, or accuracy of the information. There is no guarantee that the customer will be...

Open the catalog to page 12All Heidelberger Druckmaschinen AG catalogs and technical brochures

-

Diana Eye 42/55.

8 Pages

-

Speedmaster CX 104

13 Pages

-

Speedmaster SX 102.

20 Pages

-

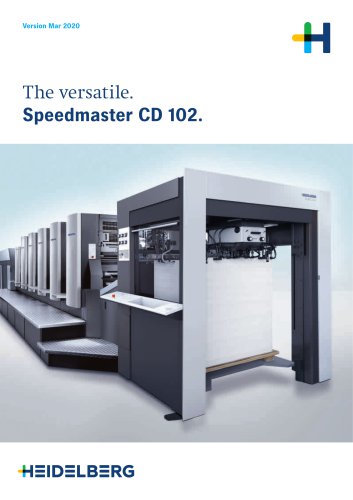

Speedmaster CD 102.

8 Pages

-

Speedmaster CS 92.

8 Pages

-

Speedmaster CX 75.

20 Pages

-

Versafire EM.

2 Pages

-

Gallus ECS 340

12 Pages

-

Versafire EP.

2 Pages

-

LabelSystem SC-20

1 Pages

-

CuttingSystem 120

1 Pages

-

Prinect Production Manager

2 Pages

-

Prinect Color Toolbox

2 Pages

-

Comfortable Production

2 Pages

-

Heidelberg CCS

7 Pages

-

Speedmaster XL 145 and XL 162

20 Pages

-

Stahlfolder TH/KH

11 Pages

-

Versafire EV

2 Pages