Catalog excerpts

Hegewald & Peschke Product Information Hot hardness testing system for tests with up to 1500°C for tests with up to 1500°C SHP1-HV01-30-1500°C Hegewald & Peschke, MeK- und Pruftechnik GmbH Am Grundchen 1, 01683 Nossen Telefon: +49 35242 445-0, Telefax: +49 35242 445-111 E-Mail: info@Hegewald-Peschke.de http://www.Hegewald-Peschke.com

Open the catalog to page 1

Product description Basic concept The system is made up of two basic components: The hot hardness testing device and the evaluation unit. The cooperation of both elements allows for a high testing capacity. The test preparations and evaluations including the log preparation can be done parallel to running tests in the kiln with the help of the evaluation unit. The dataset with all testing para-meters, including the positions, is compiled and saved at the evaluation pc with the optionally connectable measuring microscope. The sample is introduced into the hardness tester and the dataset is...

Open the catalog to page 2

The sample plates are fixed with the help of temperature-resistant wire cramps or adhesives. The reference position is transmitted from the evaluation unit to the hardness tester and back again. The hardness tester works semiautomatically. The handling of the samples with the activation of the vacuum, gas setup and the starting of the test are done manually. The procedure of heating with hold times, movement to the testing position and setting of imprints is done automatically. The combination of multiple measuring series in one dataset allows for working at different temperature steps in...

Open the catalog to page 3

The necessary test loads are generated with the help of a servo-controlled spindle drive and can be actuated with the controller. The necessary load measurement for the control of loading is integrated on the vacuum side of the probe. Thus, no shunt forces, as might occur in feedthroughs and bellows, can influence the test. With this design it is also possible to apply small test loads. A reference weight is automatically analysed with every new measuring series for a permanent control of the load sensors. This ensures that no driftings of the sensors due to vacuum and high temperatures...

Open the catalog to page 4

Hardness testing system Servo-motor-driven loading in a closed control circuit for up to 300N • Loading steps for Vickers between HV0.1 and HV30 according to DIN EN ISO 6507-1 are stored by default • Load tolerances for Vickers according to DIN EN ISO 6507-2 • Setup of hold times in the testing programme (between 5 and 60 sec.) • Setup of lowering and approximation speed by default • Automatic lowering and lifting to the reference height after hold times • Automatic control of load measurement with a reference weight at the beginning of each measuring series Shut-off thermocouple for the...

Open the catalog to page 5

Overview technical data Connection data of the system Power supply Power consumption Cooling water supply temperature supply-pipe pressure Data hardness testing probe Load Loading steps Vickers DIN EN ISO 6507-1 HV0.1 to HV30 Hold times (setup in the test 5 to 60 sec programme) Maximum speed DC motor 160 W, 3000 rpm with encoder 2500 steps Load resolution Internal data processing Data interface Indenter receiver according to customer demands Vickers, provision by customer Material of indenter elongation in Al2O3 99.9% furnace chamber Shielding plates on indenter elongation 3 x molybdenum +...

Open the catalog to page 6

Data furnace chamber Working temperature 300°C to 1500°C, ± 5K • in vacuum < 10-5 mbar 1500°C Heater pot-shaped molybdenum resistance heating Flow controller in cooling water return flow Overflow valve furnace and lock chamber 20 mbar TC1 controlling element TC2 redundant shut-off element emergency shut-off temperature > 1550°C TC3 comparing element Deviation of temperature ± 5K along sample 30 mm x 30 mm, height 3 to 8 mm Material used in the heated area (more than 100°C temperature stress) molybdenum / Al2O3 / stainless steel / copper / platinum, rhodium in TC and lock wire Material...

Open the catalog to page 7All Hegewald & Peschke Meß- und Prüftechnik GmbH catalogs and technical brochures

-

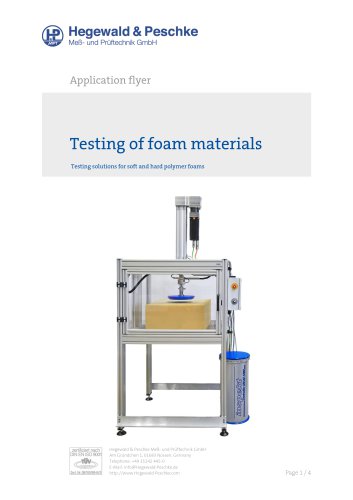

Testing of foam materials

4 Pages

-

Torsion test machine

2 Pages

-

Temperature chambers

4 Pages

-

Length measuring machine

6 Pages

-

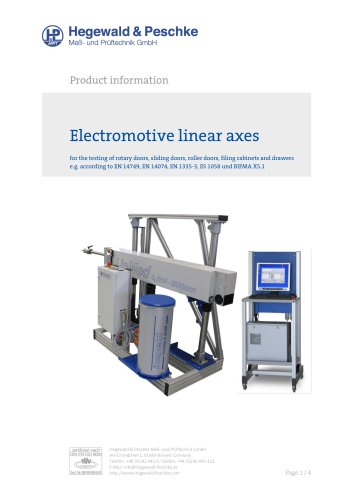

Electromechanical test axes

4 Pages

-

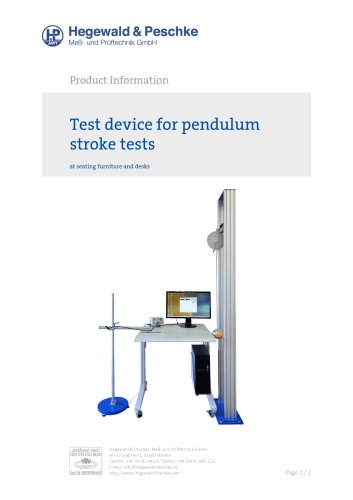

Test rig for tables

2 Pages

-

Friction test stand

2 Pages

-

Stone impact tester

2 Pages

-

Material testing on textiles

4 Pages

-

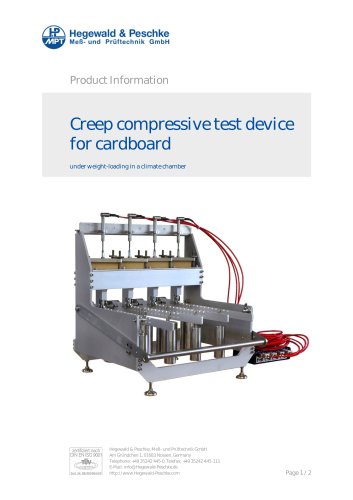

Creep testing device

2 Pages

-

Drop weights for drop test

3 Pages

-

arm rest load pad

2 Pages

-

additive weights

2 Pages

-

Creep bending test device

2 Pages

-

High temperature furnaces

4 Pages

-

Calibration machine 2500 kN

2 Pages

-

Torsion testing devices

4 Pages

-

Universal linear module

2 Pages

-

Ladder test stand

3 Pages

-

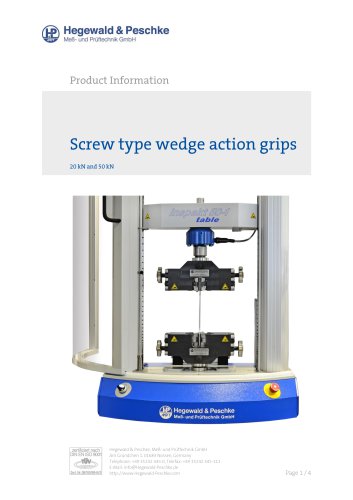

Wedge type grips

3 Pages

-

Brinell hardness tester

2 Pages

-

Magnescale Digital gauge catalog

24 Pages

-

Shock test stand

2 Pages

-

Load pads for arm rests

2 Pages

-

Friction test stand

2 Pages

Archived catalogs

-

Hydraulic grips 250kN

2 Pages