Catalog excerpts

zertifiziert nach DINEN ISO 9001 Hegewald & Peschke, MeB- und Pruftechnik GmbH Am Grundchen 1, 01683 Nossen Telefon: +49 35242 445-0, Telefax: +49 35242 445-111 E-Mail: info@Hegewald-Peschke.de http://www.Hegewald-Peschke.com

Open the catalog to page 1

/ffN Hegewald & PeschkeMe 13- und Pruftechnik GmbH System properties • Voice-coil drive for dynamic loading during static and dynamic tests in low cycle ranges • Long-term test load ±100 N, up to 50 Hz Sinus • Special design for the work with small specimen, integrated arm rests Functional description and design Tool connection with R8/3 or with M5 thread Integrated cooling of the drive, exhaust air is conducted at the back side Device is suitable for cleanrooms ISO 14644-1 class 8 Furthermore, two arm rests are installed to serve the ergonomic design of the workstation. This allows the...

Open the catalog to page 2

Component tests (micro switch) • Use of block program for test accomplishment • Test cycle is automatically saved every 10.000 cycles • The respective 10.000 load cycles were done with 10 Hz sinus with 2mm lift • Load cycles are not recorded, only limit values are supervised • The switch is connected to the 1/O of the controller and switch points are saved synchronously with the positions Veer test on soldered joints on SMD board • Positioning of the sample with a X-Y compound table • Use of different veer chisels possible • Documentation of component failure with the integrated video...

Open the catalog to page 3

Technical Data: Test load Load resolution ±140.000 Digits, class 1 (between 1% and 100 % FS ±1 % of the displayed value, according to ASTM E4, DIN EN ISO 7500 class 1) Maximum testing speed Maximum loading speed Exchangeable sensors (recommended grading 10N/50N/100N) Direct position measurement underneath the load table with a glass scale System stiffness with 100 N load sensor 4 N/pm Control with digital signal processor, 5kHz on the system bus 7 optional data acquisition cards possible Data interface LAN or USB 2.0 full speed Basic construction on a hard stone plate for passive dampening...

Open the catalog to page 4All Hegewald & Peschke Meß- und Prüftechnik GmbH catalogs and technical brochures

-

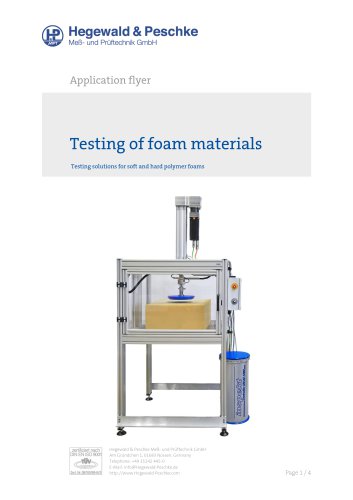

Testing of foam materials

4 Pages

-

Torsion test machine

2 Pages

-

Temperature chambers

4 Pages

-

Length measuring machine

6 Pages

-

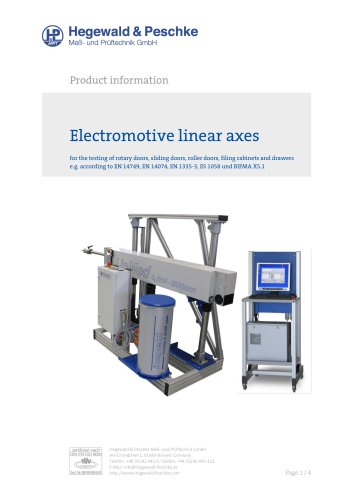

Electromechanical test axes

4 Pages

-

Test rig for tables

2 Pages

-

Friction test stand

2 Pages

-

Stone impact tester

2 Pages

-

Material testing on textiles

4 Pages

-

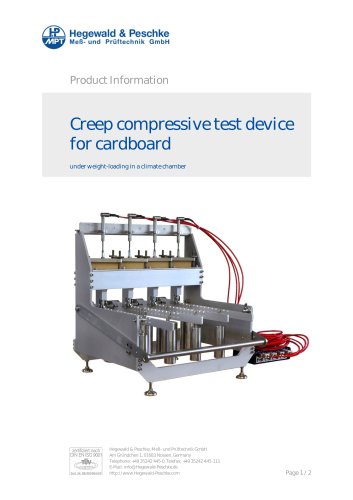

Creep testing device

2 Pages

-

Drop weights for drop test

3 Pages

-

arm rest load pad

2 Pages

-

additive weights

2 Pages

-

Creep bending test device

2 Pages

-

High temperature furnaces

4 Pages

-

Calibration machine 2500 kN

2 Pages

-

Torsion testing devices

4 Pages

-

Universal linear module

2 Pages

-

Ladder test stand

3 Pages

-

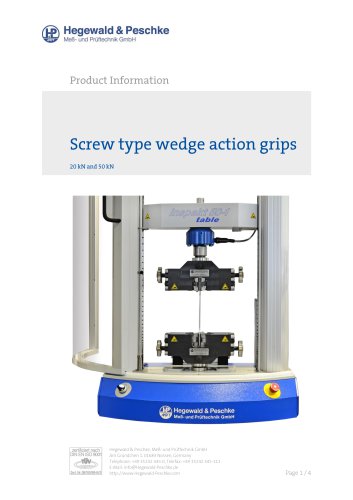

Wedge type grips

3 Pages

-

Brinell hardness tester

2 Pages

-

Magnescale Digital gauge catalog

24 Pages

-

Shock test stand

2 Pages

-

Load pads for arm rests

2 Pages

-

Friction test stand

2 Pages

Archived catalogs

-

Hydraulic grips 250kN

2 Pages