Catalog excerpts

(jB\ Hegewald & Peschke MeB- und Pruftechnik GmbH Mechanical testing of elements of microsystems technology

Open the catalog to page 1

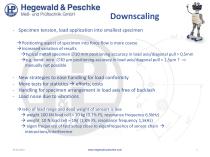

Downscaling - Specimen tension, load application into smallest specimen Positioning aspect of specimen into force flow is more coarse Increased variation of results typical metall specimen 10 mm positioning accuracy in load axis/diagonal pull > 0,5mm e.g. bond- wire 30 µm positioning accuracy in load axis/diagonal pull > 1,5µm ? manually not possible New strategies to ease handling for load conformity More tests for statistics efforts, costs Handling for specimen arrangement in load axis free of backlash Load noise due to vibrations ratio of load range and dead weight of sensors...

Open the catalog to page 2

Downscaling Effective use of measurement range at least 1/10 power less, 10.000 • digits useable Resolution of position measurement system sufficient increments, digital signals – high costs for precise systems • (accuracy < 1 µm, resolution < 0.005 µm, range > 10 mm) Possibilities of indirect position measurement limited–hystereses effects at high speed System stiffness and hystereses to correct positioning system Enhanced stiffness for dynamic tests and for fracture toughness low stifness = high energy storage stiffness has to be reproducible for correction calculations •...

Open the catalog to page 3

Application and technics Classical load range 500N > < 2MN

Open the catalog to page 4

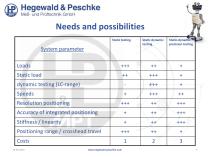

MeB- und Pruftechnik GmbH Needs and possibilities

Open the catalog to page 5

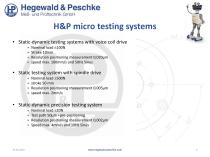

(jB\ Hegewald & Peschke MeB- und Pruftechnik GmbH H&P micro testing systems • Static-dynamic testing systems with voice coil drive » Nominal load +100N » Stroke 10mm » Resolution positioning measurement 0,020pm » speed max. 100mm/s and 50Hz Sinus • Static testing system with spindle drive » Nominal load +500N » stroke 50 mm » Resolution positioning measurement 0,005pm » speed max. 2mm/s • Static-dynamic precision testing system »! Nominal load +20N » Test path 50pm +pre-positioning » Resolution positioning measurement 0,002pm » Speed max. 4mm/s and 10Hz Sinus

Open the catalog to page 6

Inspekt micro LC 100N Static-dynamic testing machine

Open the catalog to page 7

Inspekt micro LC 100N Technical data Endurance test force up to 100N, up to maximum 50Hz sine wave, stroke 10mm Voice coil drive with direct measuring system Resolution measuring system up to 0.020µm, Gen.3µm System stiffness with 100N force sensor 4N/µm Maximum test speed vmax =100mm/sforce resolution up to 100.000.digit possible • Sensors exchangeable, gradation 10N / 50N / 100N Data acquisition rate up to 1000Hz in the software Range of view Camera zoom from 1.2x0.9mm to 6.5x5.0mm • As video microscope integrated in the test software or optionally as video extensometer ...

Open the catalog to page 8

(jB\ Hegewald & Peschke MeB- und Pruftechnik GmbH Inspekt micro LC 100N • System design Load unit/ basic unit (sectional view)

Open the catalog to page 9

H&P Testing machine software Labmaster – – – – – – – – – – Management of test templates with test and machine parameters Free programming of the travel commands via block program Management of the measurement series and storage of the raw data Force-position control, derived therefrom tension and elongation control Control according to external signals possible Switching of the control channels possible during running tests Processing of input and output signals in the program sequence Online display of the measured values in the diagram Statistical evaluationprotocol printing Integrated...

Open the catalog to page 10

H&P Testing machine software Labmaster Screenshot of the testing machine software jL«bM«M»r Dat«a»b«i* Alim: H*u V«»»ut tnmodail DriKkvrttuch Mttsitfhe: Nch*rt*tt liomd MAtchin* UKMni (Vi>m| Nutlet turn* A dwiirmtrjtei

Open the catalog to page 11

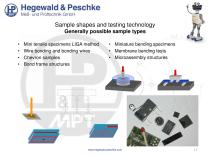

(jB\ Hegewald & Peschke MeB- und Pruftechnik GmbH Sample shapes and testing technology Generally possible sample types • Mini tensile specimens LIGA method • Miniature bending specimens • Wire bonding and bonding wires • Membrane bending tests • Chevron samples • Microassembly structures • Bond frame structures

Open the catalog to page 12

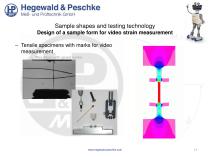

Sample shapes and testing technology Design of a sample form for video strain measurement – Tensile specimens with marks for video measurement – Wire 50µm with glued marks

Open the catalog to page 13

Sample shapes and testing technology Test of a microswitch for service life – Use of the Block Program module for conducting experiments – one test run is automatically stored every 10000 cycles – The switch is connected to the I/O inputs of the controller and the switching points are stored synchronously with the position values. – The 10000 load cycles each were run with 10Hz sine wave with 2mm stroke. – Load cycles are not recorded, only limit values are monitored

Open the catalog to page 14

Cyclic Tests utilizing bockprogramming – Testing Software LabMaster

Open the catalog to page 15

Sample shapes and testing technology Shear test on SMD assembly(1) – Board on the X-Y positioning table of the testing machine – Force measuring sensor with shearing tool – Evaluation software with video documentation of component behaviour

Open the catalog to page 16

Sample shapes and testing technology Shear test on SMD assembly(2) Example for documentation and evaluation of a component failure

Open the catalog to page 17

(jB\ Hegewald & Peschke MeB- und Pruftechnik GmbH Sample shapes and testing technology Recording hardness testing - Use of the testing machine for recording hardness testing - Correction of the penetration path with the machine stiffness

Open the catalog to page 18

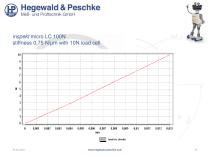

inspekt micro LC 100N stiffness 0,75 N/µm with 10N load cell LC 100 Micro Testing System

Open the catalog to page 19

(jB\ Hegewald & Peschke MeB- und Pruftechnik GmbH S 500 Static Micro Testing System Static Testing System with Spindle Drive Nominal load +500N stroke 50 mm Resolution positioning measurement 0,005pm speed max. 2mm/s stiffness 25N/pm (incl. load cell) C-framed Test System for hardness testing incl. Indentation depth evaluation as well as optical evaluation of indent Two-Column Static Test System for tensile/compression/bending and peel testing of smallest specimen

Open the catalog to page 20All Hegewald & Peschke Meß- und Prüftechnik GmbH catalogs and technical brochures

-

Testing of foam materials

4 Pages

-

Torsion test machine

2 Pages

-

Temperature chambers

4 Pages

-

Length measuring machine

6 Pages

-

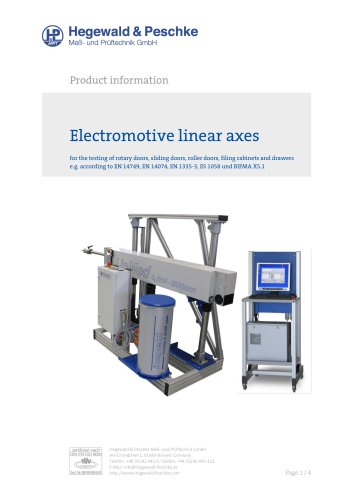

Electromechanical test axes

4 Pages

-

Test rig for tables

2 Pages

-

Friction test stand

2 Pages

-

Stone impact tester

2 Pages

-

Material testing on textiles

4 Pages

-

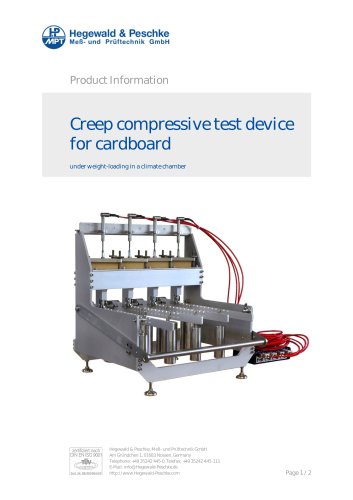

Creep testing device

2 Pages

-

Drop weights for drop test

3 Pages

-

arm rest load pad

2 Pages

-

additive weights

2 Pages

-

Creep bending test device

2 Pages

-

High temperature furnaces

4 Pages

-

Calibration machine 2500 kN

2 Pages

-

Torsion testing devices

4 Pages

-

Universal linear module

2 Pages

-

Ladder test stand

3 Pages

-

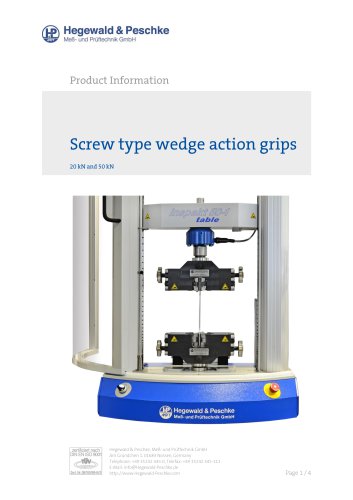

Wedge type grips

3 Pages

-

Brinell hardness tester

2 Pages

-

Magnescale Digital gauge catalog

24 Pages

-

Shock test stand

2 Pages

-

Load pads for arm rests

2 Pages

-

Friction test stand

2 Pages

Archived catalogs

-

Hydraulic grips 250kN

2 Pages