Catalog excerpts

(lB\ Hegewald & Peschke MeB- und Pruftechnik GmbH

Open the catalog to page 1

'WEST MelB- und Pruftechnik GmbH Content > What are Plastics? > Material Testing on Plastics > Test & Standards > ISO527:2012; changes towards THE version from 1993 > Requirements on UTM >-H&P solutions for polymer mechanical testing > Machine configurations > Applications/ Examples

Open the catalog to page 2

“any one of a large number of synthetic usually organic materials that have a polymeric structure and can be moulded when soft and then set, esp. such a material in a finished state containing plasticizer, stabilizer, filler, pigments, etc. Plastics are classified as thermosetting (such as Bakelite) or thermoplastic (such as PVC) and are used in the manufacture of many articles and in coatings, artificial fibres, etc.” https://CollinsDictionary.com “Plastic is a material consisting of any of a wide range of synthetic or semi-synthetic organics that are malleable and can be molded into solid...

Open the catalog to page 3

Plastics The mechanical properties depend on: • chemical constitution • primary structure - tacticityof ligands - isomery (head-tail, stereo, rotation) - branches - chemical blocks - grafting structure - molecular weight - crosslinks • secondary structure - Thermoplastics - amorphe or semi crystalline - Duroplastics-mainly crosslinked - Elastomers - mainly crosslinked

Open the catalog to page 4

'vssr MeB- und Pruftechnik GmbH Plastics Low cost - ease of manufacturing - versatility - mainly organic compounds Extruded-Injection molded-Textiles-Foils-Packaging-Yarns-Composites-Blends-. Thermoplastic Extrudes Polymer Blends Fillers (isotrope) Composites (anisotrope) l^Oraebonifl Carbcn PifrPtifl O’ Cw-yw Ij* Up-FrflPneg W Degree Ljp1 Up Cm bon PW?i*g O' Decree Liy Up z C'Jnm t*r6pTtg 90 Dear« iuqt Ut> UhKO‘+K*^i PrePittg D‘ Oyw La* Up VJqn*r\ CirtKHT- PraPrag MTrt

Open the catalog to page 5

Static tests Iosipesco test Application: DU Laminate, Cross Ply Standard: ASTM D5379 Test specimen, grain direction 0° or 90° [1] Advantages: Cost-effective specimen preparation Very accurate test results Test bench for simple compression test Standardized according to ASTM D5379 Disadvantages: Special specimen holder No pure shear load Scheme Wyoming experimental setup [1]

Open the catalog to page 7

Static tests: thrust 45° tensile test Application: Cross-Ply, ±45° balanced and symmetrical Standard: EN ISO 14129, ASTM D3518 Similar: DIN 65466 Disadvantages: Biaxial stress state No pure shear load y Advantages: Cost-effective specimen preparation Very accurate test results Test bench for simple tensile test Simple experimental setup e Measurement of only 2 directions of elongation necessary Standardised according to EN ISO 14129 or ASTM D3518 r- Tab Longitudinal strain gauge

Open the catalog to page 8

Hegewald & PeschkeTests and Standards Static tests: thrust 10° tensile test No uniform specimen specification Sensitive to bending/twisting, i.e. bending stresses in width/thickness direction < 3%. Application: UD laminate Advantages: Cost-effective specimen preparation Very accurate test results Test bench for simple tensile test Simple experimental setup No special specimen holder required Disadvantages: Biaxial stress state Measurement of 3 directions of strain No standardization according to ISO or ASTM, but the use of ISO 527 is possible

Open the catalog to page 9

Static tests: thrust 3-Rail shear test Application: UD laminate (0° or 90° to the longitudinal axis of the rails) Standard: ASTM D4255 Advantages: Good test results Test bench for simple tensile/compression test Standardization according to ASTM D4255 Disadvantages: Large test specimen Elaborate preparation of the test specimen (drill holes) Complex specimen collection High cost

Open the catalog to page 10

Static tests: thrust 2-Rail shear test Application: UD laminate (0° or 90° to the longitudinal axis of the rails) Standard: ASTM D4255 Advantages: Test bench for simple tensile/compression test Standardization according to ASTM D4255 Pure shear force applied in the area of the strain gages Disadvantages: Large test specimen Elaborate preparation of the test samples (drill holes) Complex specimen collection High cost

Open the catalog to page 11

Static tests: special tests Biaxial tests for failure bodies Biaxial tensile load Torsion/tension/compressive load 2D & 3D fractured bodies according to Cuntze failure criterion [5]

Open the catalog to page 12

(lB\ Hegewald & Peschke MeB- und Pruftechnik GmbH Sectionl general guidelines Section 2 test conditions for form and extruded materials Section 3 test conditions for foils and tablets Section 4 test conditions for isotrope and anisotrope fibre reinforced composites Section 5 test conditions for unidirectional fibre reinforced composites • For single phase plastics and blends, filled and unfilled, fibre reinforced materials, extruded and molded plastics, foils and plates, machine acc. ISO 5893 • Length measuring displayed with uncertainty better than 1%, i.e. for modulus ±1^m, i.e. with...

Open the catalog to page 13

ISO 527 Normative changes in 2012 Increase Lo for 1A specimen from 50 to 75mm^ Two different possibilities of strain display • Nominal strain on basis of LoT ALo £ = Lo benefit for Youngs modulus Detailed description of poisson ratio Demand on measuring frequence Change of speed after modulus determination allowed, but before 0.3% strain (9.6) Various tests can be conducted with one specimen (modulus + test to fracture) Definition of tolerance to specimen thickness (hmax-h)< 0.1mm Value of precision Normative appendix for computer supported determination of yielding point Detailed...

Open the catalog to page 14

(lB\ Hegewald & Peschke MeB- und Pruftechnik GmbH ISO 527 stress-strain graphs • Yield stress ay: first stress, when no stress 08increase at increase of strain • Modulus between 0.05% and 0.25% • Nominal strain: related to LoT U for strains beyond any yielding point • Strain until yielding point related to Lo

Open the catalog to page 15

Method A ISO 527 strain display Method B New in version 2012 - one plot Two graphs needed to display all results Ey via long travel extensometer Especially with optical ext. 2-sided measurement is suggested, in any case deformation and flexural effects must be avoided

Open the catalog to page 16All Hegewald & Peschke Meß- und Prüftechnik GmbH catalogs and technical brochures

-

Testing of foam materials

4 Pages

-

Torsion test machine

2 Pages

-

Temperature chambers

4 Pages

-

Length measuring machine

6 Pages

-

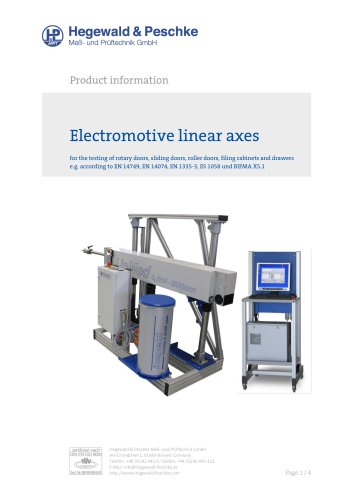

Electromechanical test axes

4 Pages

-

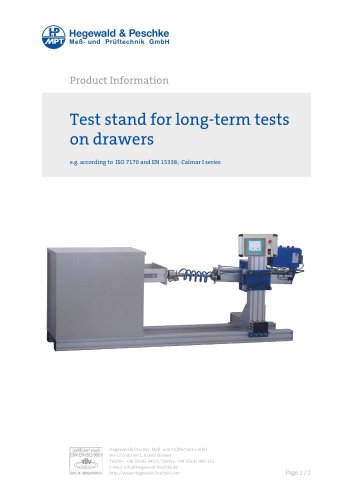

Test rig for tables

2 Pages

-

Friction test stand

2 Pages

-

Stone impact tester

2 Pages

-

Material testing on textiles

4 Pages

-

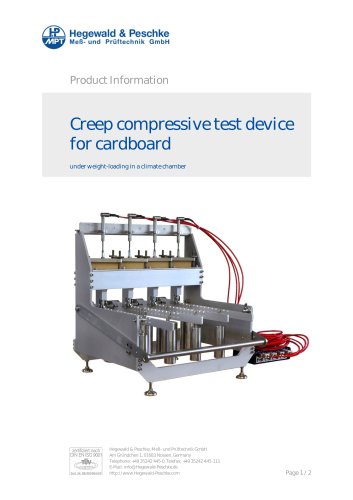

Creep testing device

2 Pages

-

Drop weights for drop test

3 Pages

-

arm rest load pad

2 Pages

-

additive weights

2 Pages

-

Creep bending test device

2 Pages

-

High temperature furnaces

4 Pages

-

Calibration machine 2500 kN

2 Pages

-

Torsion testing devices

4 Pages

-

Universal linear module

2 Pages

-

Ladder test stand

3 Pages

-

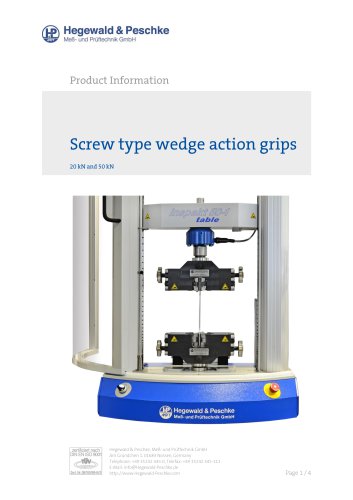

Wedge type grips

3 Pages

-

Brinell hardness tester

2 Pages

-

Magnescale Digital gauge catalog

24 Pages

-

Shock test stand

2 Pages

-

Load pads for arm rests

2 Pages

-

Friction test stand

2 Pages

Archived catalogs

-

Hydraulic grips 250kN

2 Pages