Website:

HDD Sweden AB

Website:

HDD Sweden AB

Group: Tolerans Group AB

Catalog excerpts

HDD Servo Motors AB MANUAL HDD Servo Motors AB Motor Manual

Open the catalog to page 1

Safety Advices All operations on transport, assembly, start-up and maintenance must be done by skilled and qualified personnel only. The qualified personnel must know and observe the following standards and guidelines: DIN VDE 0105, IEC 364, accident prevention regulations. Deviant behaviour may cause serious injury to persons and may lead to damages. Before mounting and start-up carefully read the documents on hand. Follow the instructions for power supply (motor label and manual) and go by the rules of the technical data. Ensure a proper, low-impedance grounding of the motor housing with...

Open the catalog to page 3

A power reduction might possibly be necessary in case of tolerances to the a.m. environmental conditions. The motors are not suitable for outdoor installation or installation within aggressive or foreign substance afflicted atmosphere. Drive elements The rotor of the motor has been electronically counterbalanced during production. Before fitting your drive elements onto the shaft end, please remove the corrosion prevention (if existing). Strictly use suitable tools for fitting or removing the drive elements and follow the advices of the drive element manufacturer to avoid damages. Our...

Open the catalog to page 4

Motor series HDD Servo Motors AB offers four series of brushless, permanent-magnet servo motors, based on the same patented ultra-compact technology. HSM – 20 pole hollow shaft motors HDD – 20 pole shaft motors HSM motors allow cables, hoses, rotating shafts, etc. to pass through the servomotor’s own shaft. They have 20 poles = 10 pole pairs. HDD and ICM motors can be equipped with a range of different feedback systems (resolver, SICK/Stegmann Hiperface or Heidenhain Endat). These motors can optionally be equipped with a holding brake. The HSM motors are only available with Hiperface...

Open the catalog to page 5

Insulation system The insulation system complies with the requirements of EEC LV Directive 73/23/EEC and 93/68/EEC. Test report E9911111E01. Overtemperature protection and thermistors As a standard, HDD motors are equipped with overtemperature protection. The protection consists of three PTC thermistors in series, one for each phase. The PTC thermistors are manufactured according to norms DIN 44081 and DIN 44082. According to these norms, the resistance for a single thermistor at room temperature is in the range 20 Ohms - 250 Ohms. For three thermistors in series, the total room temperature...

Open the catalog to page 6

Holding brake HDD, ICM and HDT motors (but not HSM motors) have the option of an installed brake. The permanent-magnet brake is operated by 24 VDC and blocks the rotor when being without voltage. The brake is to be understood as a holding brake and it is not to be used for permanent slow downs during production. When the brake is detached the rotor can operate without residual torque, the functioning is free from backlash. The brakes can be operated directly by the inverter . In this case the reset of the brake winding is effected without additional external wiring. If the brake is not...

Open the catalog to page 7

The different fields in a motor type name, e.g. HDD 09J- Pa- Az- Az- A- A- AAA, contain the following information: Motor type HDD 09J- Pa- Az- Az- A- A- AAA HDD 20 pole shaft motor ICM 20 pole internal coupling motor HSM 20 pole hollow shaft motor HDT 10 pole shaft motor Flange size HDD 09J-Pa- Az- Az- A- A- AAA Approximate flange size in cm: 09 series 92 mm Stator length HDD 09 J- Pa- Az- Az- A- A- AAA A single letter indicates the stator length; the later the letter’s position in the alphabet, the longer the stator. Currently the following lengths are available: For 09...

Open the catalog to page 8

The physical size of the motors depend on the choice of feedback, du to the size of the different transducers, cf the figure below: Connector HDD 09- Pa- Az- Az- A- A- AAA This field specifies the connector type and location. The letters A, B, C, D, K and L are used for 4+3+PE power connectors, E, F, G, H, M and N are used for 5+PE power connectors, and P, Q, S, T, U, V for 5+3+PE. However, for legacy reasons motors with pinnings suitable for Parker and Siemens drives use the first series of letters, despite their six-pole connectors. For a detailed specification of the mounting and...

Open the catalog to page 9

Siemens Baumüller Y-Tec Not all feedback types are presently available with all pin-out suffices. Brake HDD 09– Pa– Az– Az– A– A– AAA A = no brake, D = holding brake. Shaft key/sealed HDD 09– Pa– Az– Az– A– A– AAA A = shaft with keyway (standard), B = shaft without keyway. C = sealed motor, shaft with keyway D = sealed motor, shaft without keyway X = special. Contact HDD for details. Options HDD 09– Pa– Az– Az– A– A– AAA AAA = standard. For other options please contact HDD.

Open the catalog to page 10

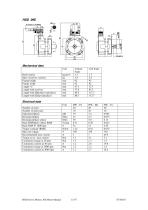

Mechanical data Electrical data HDD Servo Motors AB Motor Manual

Open the catalog to page 11

Torque versus speed Data were measured on an HDD 09E-Pa series motor mounted on a vertical 260 x 200 x 12 mm aluminum plate in free air, with a winding temperature rise of 90°C and driven by a commercially available inverter. Continuous torque and 25% duty cycle (1 minute on, 3 minutes off): HDD 09E-Pa at 560V rail voltage Low speed, HDD09E-Pa Relative kT vs commanded current 4.2A Maximum load on shaft at life expectancy 20,000 h Maximal axial load (push): 350 N at 500 rpm, 100 N at 3000 rpm. Maximal axial load (pull): 50 N at all speeds. Maximal radial load at zero axial load is given...

Open the catalog to page 12

Mechanical data Electrical data HDD Servo Motors AB Motor Manual

Open the catalog to page 13

Torque vs speed Data were measured on an HDD 09J–Pa series motor mounted on a vertical 260 x 200 x 12 mm aluminum plate in free air, with a winding temperature rise of 90ºC and driven by a commercially available inverter. Continuous torque and 25% duty cycle (1 minute on, 3 minutes off): 6 5 4 100% Short term torque Low speed, HDD09J–Pa Relative kT vs commanded current 1.2 1 kT relative Maximum load on shaft at life expectancy 20,000 h Maximal axial load (push): 350 N at 500 rpm, 100 N at 3000 rpm. Maximal axial load (pull): 50 N at all speeds. Maximal radial load at zero axial load is...

Open the catalog to page 14All HDD Sweden AB catalogs and technical brochures

-

HDD 14 Solid Shaft Motors

2 Pages

-

ICM The Coupmotor®

2 Pages

-

HSM Hollow Shaft Motors

2 Pages

-

HDT 09 High Speed Motors

2 Pages

-

HDD 09 Solid Shaft Motors

2 Pages