Catalog excerpts

Product Catalogue The next Generation. Temperature Control Units

Open the catalog to page 1

The next Generation. The technology of the Thermo-6 temperature control units builds on the extremely successful Thermo-5 series. With over 100 000 units in use, HB-Therm has become the global market leader. The unit technology is persistently focused on quality and durability. HB-Therm backs this with a lifetime warranty on the core components of the heater and now also on the flow meter. "Just better" stands for the consistent advancement of our technology. Table of Contents Highlights Technical Data Thermo-6 Technical Data Gate-6 The next Generation. Temperature Control Units 3

Open the catalog to page 2

Intelligently networked Ethernet (OPC UA) is standard for us. The forward-looking hardware and software architecture gives you access to the digital world. Control, analyse and manage – all at once Unrivalled Lifetime warranty on heating and flow meter. Process data recording, unit history, unit-specific documents such as certificates, calibration data, operating and assembly instructions – everything is displayed quickly and clearly. Pure energy efficiency No failures. Ultra-low maintenance Speed-controlled pump as standard underlines our commitment to the environment. The Energy-Control...

Open the catalog to page 3

The unit The proven as base and improvement potentials consistently implemented: The result is a unit technology that is unsurpassed in terms of functionality and serviceability. Lifetime warranty on heater and flow meter does not allow any com promises. Energy efficiency has been redefined with a new pump technology combined with speed control. An Ethernet interface for communication with the injection moulding machine or the HB-Therm interface server Gate-6 is included in the extensive standard equipment. High control accuracy ±0,1 °C Shortest heating and cooling times Short response...

Open the catalog to page 4

Operation Everything at a glance: The 7 inch IPS touch screen sets new standards in brilliance and speed. The intuitive user interface in the local language provides quick access to the desired functions. Energy-Control, Trend Graph and Dashboard clearly display the important information at a glance. Intelligent assistance systems support the user during commissioning, energy optimisation and process monitoring. 7 inch IPS touch screen Intuitive Proven logic Operation in local language Everything at a glance Energy-Control Dashboard Trend graph → Forward-thinking → Self-diagnosis →...

Open the catalog to page 5

Your possibilities The temperature control units Thermo-6 are as a standard equipped with an Ethernet interface and communicate via OPC UA with the injection moulding machine or further advanced systems. Combined with an interface server Gate-6 completely new possibilities arise for the user. The Android app “e-cockpit” sends analysis data on the touch of a button or allows the remote access to the unit by a HB-Therm specialist. Additional possibilities are the remote control of a unit and granting access to any external person. Naturally, we adhered to the highest safety standards when...

Open the catalog to page 6

Data security Highest security standards vouchsafe data protection and safety. Remote access or upload of analysis data are only initiated after explicit user approval. Our gateway to the digital world Products and solutions instead of concepts and theories! Gate-6 and “e-cockpit” are the concrete answer to today's needs and future challenges in the digitalisation of temperature control technology. Control, analyse and support – from anywhere and at the touch of a button Control from anywhere via e-cockpit Work even more efficiently and safely with “e-cockpit” on your mobile device. Call up...

Open the catalog to page 7

Technical data Tools Interface server Gate-6 The Thermo-6 temperature control units communicate with the machine control via Ethernet. This can be done either directly via OPC UA or via the Gate-6 interface server. The interface server Gate-6 is capable of translating Euromap 82.1 into various proprietary machine protocols. These are: “Knowledge” gives you access to all you need to know for operation and use Series-6 units. QR-Codes * on the unit can be used to call up the latest information. On a PC “Know ledge” is accessed from within the “Ticket” system This gives you access to operating...

Open the catalog to page 8

Technical data Technical data Standard equipment Topic Speed-controlled, sealless pump in stainless steel, IE4 OPC UA interface (EUROMAP 82.1, OPC 40082-1) Switch with 2 RJ-45 sockets Heating elements without direct contact to the heat transfer medium HB-Therm data interface CAN for connection of flow meters Flow-5 1 Sub-D 15-pin socket (female) Continuous, maintenance-free ultrasonic flow meter USB Low-scaling cooling system with plate heat exchanger Connection for software updates and export of historical data USB-A Proportionally controlled cooler bypass (on units above 100 °C) Pressure...

Open the catalog to page 9

Technical data Special executions Colour Technical data Adapter for central coupling, main line / return line Adapter for central coupling, main line / return line including filter in main line RAL 7035 (glossy light grey) Adapter for central coupling, cooling water 4-way manifold with shut-off valves RAL 9011 (matt graphite black) 4-way manifold with shut-off valves and filter in main line Custom colour Custom colour Side panels Code RAL 5015 (glossy sky blue) Custom colour Front panels C004 'colour' * Electrical Interface cables, mains connectors and other, refer to accessories program...

Open the catalog to page 10

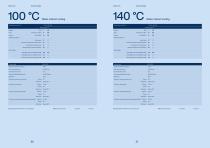

Technical data 100 °C Temperature control unit Water, indirect cooling Type Technical data Temperature control unit Housing size Leak stopper Connection for alarm and external control Connection for external sensor Mould evacuation with compressed air Pump Cooling Water, indirect cooling Type Leak stopper Connection for alarm and external control Connection for external sensor Mould evacuation with compressed air Additional equipment Additional equipment Mains voltage Mains voltage Technical Data Technical Data Maximum main line temperature Maximum main line temperature Flow rate...

Open the catalog to page 11All HB-THERM catalogs and technical brochures

-

Cleaning Unit Clean-5

7 Pages

-

Water Treatment Unit Treat-5

7 Pages

-

Flow Meter Flow-5

15 Pages

-

Switching Unit Vario-5

11 Pages

-

Cleaning Unit

7 Pages

-

Water Treatment Unit

7 Pages

-

Flow Meter

15 Pages

-

Temperature Control Units

19 Pages