Catalog excerpts

Switching Unit for Variothermal Control Product Catalogue 2017-10

Open the catalog to page 1

HB-THERM*VARIQ-5 Certain challenges in injection moulding cannot be overcome with classical mould temperature control. The solution is a variothermal control: High temperature during injection, cold temperature in the cooling phase. Together with two temperature control units, the Vario-5 forms a variothermal system according to the fluid-fluid technique. Alternatingly, it links either the hot or the cold unit to the same circuit. It is quite possible to use existing moulds if the temperature control channels are suitably arranged. Vario-5 provides easy and quiet operation. It supports the...

Open the catalog to page 2

Standard Equipment Hydraulics Closed hydraulic system without oxygen contact Buffer volume Maintenance-free, pressure shock-free Hydraulic circuit made of non-corroding materials Functions Wizards determine setpoint temperatures, delays and switching times Monitoring / Safety Monitoring of the switching procedures Automatic limit value settings for temperatures and flow Electrically operated valves (no compressed air) Lockable and abrasion resistant castors (PUR) Fibre-free insulation Command / Display Large choice of display windows and values Storage of specific variothermal...

Open the catalog to page 3

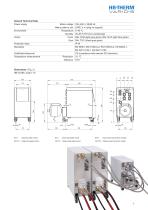

Technical Specifications • Standard specification O Optional 1) Recommended for mould circuits of 0,9 L and larger 2) For detailed information and other lenghts g Accessories program (D8064-EN) Recommendation for Unit Type Thermo-5 Hot water circuit Thermo-5, HB-160 or HB-180, pump 4M, heating and cooling power depends on application Cold water circuit Thermo-5, HB-140, pump 4M, heating and cooling power depends on application (if the unit for the hot water circuit is run at over 160 °C, the unit for the cold water circuit must be equipped with a 17 bar safety valve and a manometer 25...

Open the catalog to page 4

□ Command 1) Command deactivated

Open the catalog to page 5

General Technical Data Power supply Mains voltage Mains cable to unit Temperature Environment Humidity Cover Colour Door Protection class Standards Certification/Approval Resolution Temperature measurement Tolerance 100–240 V, 50/60 Hz LNPE, 4 m (plug on request) 5–40 °C 35–85 % RH (non-condensing) RAL 7035 (light grey gloss), RAL 5012 (light blue gloss) RAL 7021 (black-grey gloss) IP 44 EN 50581, EN 61000-6-2, EN 61000-6-4, EN 60204-1, EN ISO 13732-1, EN ISO 12100 CE (compliance with relevant CE directives) 0,1 °C ±3 K Input hot water circuit Output hot water circuit OUT C Output cold...

Open the catalog to page 6

In injection moulding some typical problems cannot be solved by traditional temperature control: • visible weld lines in optically critical areas. • incomplete moulding of the finest structures and lacking contour accuracy (e.g. for optical lenses, micro- or nanostructures, piano lacquer) • insufficient surface quality of foamed and fibre-reinforced parts • excessively high injection pressures for extremely small cross-sections • sink marks at extreme wall thickness ratios Reasons: In injection moulding the hot plastic melt meets a relatively cool mould surface in the injection phase. The...

Open the catalog to page 7

The Process The fluid-fluid technique sends alternatingly hot and cold temperature control medium through the temperature control channel immediately below the cavity surface, controlled by the machine cycle. The temperatures are set on the two temperature control units. If there is a temperature sensor available at a suitable position in the mould, the switch-over or the start of injection can also be made depending on the mould temperature to increase process reliability. Thermo-5 Cold water circuit Operating mode: Heating Thermo-5 Cold water circuit Operating mode: Cooling Control Cyclic...

Open the catalog to page 8

Frame Conditions In variothermal control the temperature at the surface of the cavity will be actively changed within the injection cycle. The area around the cavity is thus cyclically heated and cooled. Depending on the configuration of the temperature control channels the temperature at the surface of the cavity reacts stronger or weaker and the area is larger or smaller. To efficiently achieve the largest temperature gradients possible the following is recommended: Distance of the temperature control channel from the surface of the cavity Variothermal mass Isolation Connections...

Open the catalog to page 9

HB-Therm worldwide. HB-Therm is one of the leading manufacturers of temperature control units worldwide. Since 1967 HB-Therm AG has been developing and producing innovative temperature control technology to the highest quality standards. With its comprehensive know-how and motivated workforce, the company has succeeded in becoming the technology leader in its sector. This Swiss family enterprise employs around 130 staff and has established itself as a systems supplier offering seamless customer support from machine design through to a complete after-sales service. Production is...

Open the catalog to page 10

HB-THERM AG Spinnereistrasse 10 (WU 3) Postfach 9006 St. Gallen Switzerland Phone +41 71 243 6-530, Fax -418 info@hb-therm.ch, www.hb-therm.ch Distributors Australia (AU) Parrington Group Pty. Ltd., Magill SA 5072 Austria (AT) Luger Gesellschaft mbH, 3011 Purkersdorf Belgium (BE) AJ Solutions BVBA, 2240 Zandhoven Brazil (BR) HDB Representagoes Ltda, Cotia (SP) 06705-110 China (CN) ARBURG (Shanghai) Co., Ltd., 201100 Shanghai ARBURG Machine & Trading, 518108 Shenzhen Dongguan Cenglary Trading Co., Ltd., 523850 Dongguan City Tianjin Cenglary Trading Co., Ltd., 300452 Tianjin City Jiangsu...

Open the catalog to page 11All HB-THERM catalogs and technical brochures

-

Thermo-6

19 Pages

-

Cleaning Unit Clean-5

7 Pages

-

Water Treatment Unit Treat-5

7 Pages

-

Flow Meter Flow-5

15 Pages

-

Switching Unit Vario-5

11 Pages

-

Cleaning Unit

7 Pages

-

Water Treatment Unit

7 Pages

-

Flow Meter

15 Pages

-

Temperature Control Units

19 Pages