Catalog excerpts

hv 450/630 AP2 | hv 460/660 AP2-V hv 800 AP2-V | hv 800 AP4-V VACUUM IMPULSE WELDING MACHINES FOR INDUSTRIAL AND MEDICAL PACKAGING

Open the catalog to page 1

SAFETY: The validation of packaging processes is crucial to ensure that sterile barrier system integrity is attained and will remain so until opened by the users. The international packaging standard ISO 11607-2 stipulates a packaging process that can be validated and is reproducible. The critical process parameters must be documented routinely (Monitoring). All hawo-products marked with V meet the requirements of this standard. Other device features facilitate the packaging process and contribute to greater safety: > Clearly laid out control panel with backlit display for easy setting of...

Open the catalog to page 2

After the machine is connected to an external compressed air supply, the packaging process with a vacuum impulse welding machine runs through four stages (see figures). The bag is placed over the nozzles and positioned between both weld stamps. The rubber on the weld stamps guarantees that the bag is airtight. Pressing the foot switch of the vacuum impulse welding machine closes the welding stamps and starts the vacuum welding process: The vacuum pump switches on and sucks the air from around the product. As soon as the vacuum time is over, the nozzles are withdrawn automatically. The weld...

Open the catalog to page 3

TECHNICAL DATA Fraunhofer IPA Qualification Seal (Air cleanliness class 6 in accordance with ISO 14664-1) CE sign and GS-certified x POWER SUPPLY DATA Mains connection | frequency 230/115 V | 50/60 Hz 230/115 V | 50/60 Hz Power (only during packaging process) 2800 Watt 2800 Watt Fuse protection 16 A, characteristic curve G (K) 16 A, characteristic curve G (K) MECHANICAL DATA Dimensions w x d x h Casing Weight Welding seam width Welding seam length 880 x 490 x 280 mm Stainless steel AISI 304 43 kg 8 mm 770 mm x 230/115 V | 50/60 Hz 2800 Watt 16 A, characteristic curve...

Open the catalog to page 4

ELECTRONIC FEATURES, OPERATION AND COMMUNICATION Welding system Control IEC Protection Classes Parameter settings remain even after a power failure (autosafe) Display Interface connections Key lock Piece counter PROCESS PARAMETER AND CONTROL FUNCTIONS IN ACORDANCE WITH ISO 11607-2 Welding temperature Welding time Contact pressure Cooling temperature Cooling time Process course Machine stop in case the parameters exceed predetermined limits Warning systems in case the parameters exceed predetermined limits Compatible with ht 180 PT-USB (process documentation system) Compatible with hawo...

Open the catalog to page 5

ht 180 PT-USB PROCESS DOCUMENTATION VIA USB-STICK. Following the requirements set out in the ISO 11607-2 standard, the routine monitoring and documentation of the process parameters can be carried out with the help of a USB stick and the hawo ht 180 PT-USB storage unit. The process protocols can then be called up, digitally signed and archived on a PC. hawo viu-2 TEST SYSTEM FOR MONITORING THE INTEGRITY OF SEALS The hawo viu-2 is used for the non-destructive visual inspection of sealing seams for flexible packaging in accordance with ISO 11607-2. It can be used for spot checks as well as...

Open the catalog to page 6All Hawo catalogs and technical brochures

-

hm 4000 DC-VI

6 Pages

-

hd 650 D/DE/DC EcoPak

3 Pages

-

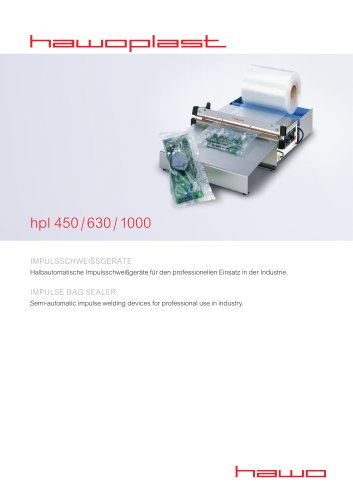

hpl 500 D/D-V

2 Pages

-

Bowie & Dick-Test

2 Pages

-

ht 150 SCD

4 Pages

-

hm 750 WST

2 Pages

-

hm RS

2 Pages

-

hm 2010/2015/2020 WST

4 Pages

-

hm 8000 AS/AS-V SealCut

6 Pages

-

hpl WSZ

2 Pages

-

hpl ISZ

2 Pages

-

hpl 3000 DC-V

8 Pages

-

hpl 300 BMS / hpl 500 BMS

2 Pages

-

hpl 450 TSM

2 Pages

-

hpl 1500 / hpl 1800 MS-3

2 Pages

-

hp 630 WS

8 Pages

-

hd 680 DE

4 Pages

-

hd 680 DEI-V

4 Pages

-

hd 320 MS

4 Pages

-

hd 380 WSI-V ValiPak®

2 Pages

-

hawo viú-2

2 Pages

-

hm 300 BMS / hm 500 BMS

2 Pages

-

hm 450 / hm 630 AS-8

2 Pages

-

hm 460 AS-V / hm 660 AS-V

4 Pages

-

hm 780 DC-V

6 Pages

-

hm 850 DC-V / hm 880 DC-V

6 Pages