Website:

Hawle

Website:

Hawle

Catalog excerpts

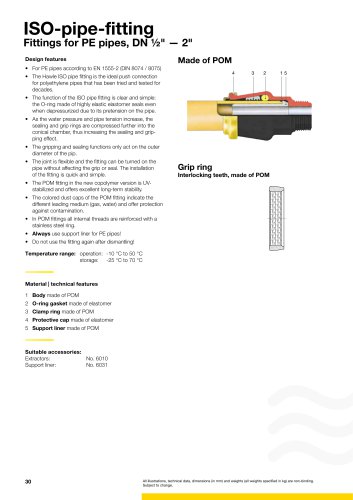

Fittings for PE pipes, DN ½" — 2" Design features • For PE pipes according to EN 1555-2 (DIN 8074 / 8075) • The Hawle ISO pipe fitting is the ideal push connection for polyethylene pipes that has been tried and tested for decades. • The function of the ISO pipe fitting is clear and simple: the O-ring made of highly elastic elastomer seals even when depressurized due to its pretension on the pipe. • As the water pressure and pipe tension increase, the sealing and grip rings are compressed further into the conical chamber, thus increasing the sealing and gripping effect. • The gripping and sealing functions only act on the outer diameter of the pip. • The joint is flexible and the fitting can be turned on the pipe without affecting the grip or seal. The installation of the fitting is quick and simple. Grip ring Interlocking teeth, made of POM • The POM fitting in the new copolymer version is UVstabilized and offers excellent long-term stability. • The colored dust caps of the POM fitting indicate the different leading medium (gas, water) and offer protection against contamination. • In POM fittings all internal threads are reinforced with a stainless steel ring. • Always use support liner for PE pipes! • Do not use the fitting again after dismantling! Temperature range: operation: -10 °C to 50 °C storage: -25 °C to 70 °C Material | technical features 1 Body made of POM 2 O-ring gasket made of elastomer 3 Clamp ring made of POM 4 Protective cap made of elastomer 5 Support liner made of POM Suitable accessories: Extractors: No. 6010 Support liner: No. 6031 All illustrations, technical data, dimensions (in mm) and weights (all weights specified in kg) are non-b

Open the catalog to page 1

ISO pipe fitting instruction for assembly and dismantling Assembly - for gas always use new fittings 1 The sealing surface of the pipe must be smooth, clean and scratch-free! Always use support liner No. 6031 NO OIL ! Pull out the pipe with a slight turn 3 Moisten with water or lubricants (see page 37) Disassembled fittings should be recycled! 10 Pressure test on installed line and exposed, unfilled connections Max. torque for tightening the threads (observe pipe fitter rules acc. to national standards): ¾" 1" 1¼" 1½" 25 Nm 40 Nm 42 Nm 42 Nm

Open the catalog to page 2

Fittings for PE pipes, DN ½" — 2" • For PE pipes according to EN 1555-2 (DIN 8074/8075) Order Ø Pipe no. 25 32 40 6125 50 63 Design feature • With internal thread according to ISO 228 • For PE pipes according to EN 1555-2 (DIN 8074/8075) Order Ø Pipe Thread no. 25 ¾" 32 1" 40 1¼" 6225 50 1½" 63 2" External thread No. 6125 Made of POM ØD • With external thread according to EN 10226-1 Internal thread No. 6225 Made of POM Design feature Connector reduced No. 6335 Made of POM ØD Design feature All illustrations, technical data, dimensions (in mm) and weights (all weights specified in kg) are

Open the catalog to page 3

Fittings for PE pipes, DN ½" — 2" Design feature • For PE pipes according to EN 1555-2 (DIN 8074/8075) Order no. Order Ø Pipe Ø Pipe MOP L E 1 2 no. (PN) 6491 40 32 4 102/87 84 Design feature • With internal thread according to ISO 228 Elbow 90° With internal thread No. 6435 Made of POM Design feature • With internal thread according to ISO 228 • For PE pipes according to EN 1555-2 (DIN 8074/8075) Ø Order no. Pipe 32 40 6525 63 T-piece with threaded outlet No. 6525 Made of POM

Open the catalog to page 4All Hawle catalogs and technical brochures

-

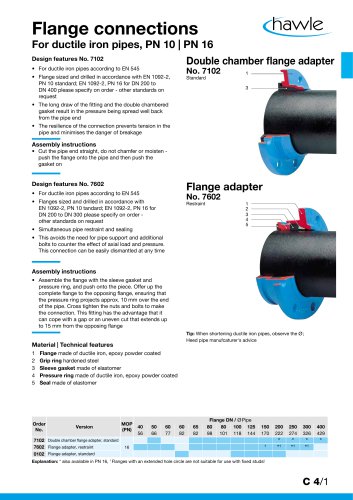

Flange connections

2 Pages

-

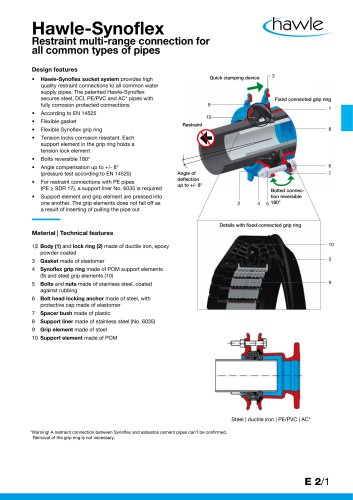

Hawle-Synoflex

2 Pages

-

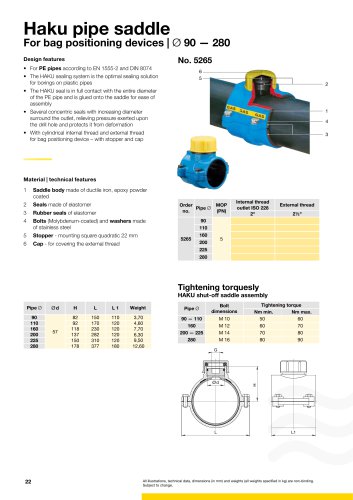

Haku pipe saddle

1 Pages

-

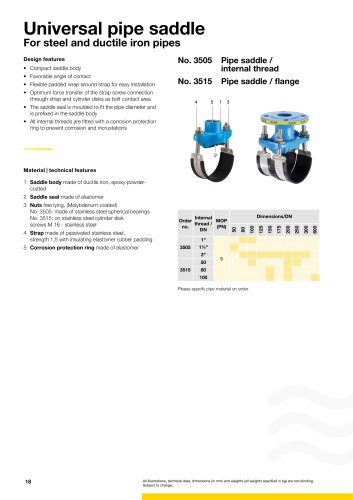

Universal pipe saddle

2 Pages

-

ERU ® K1

9 Pages

-

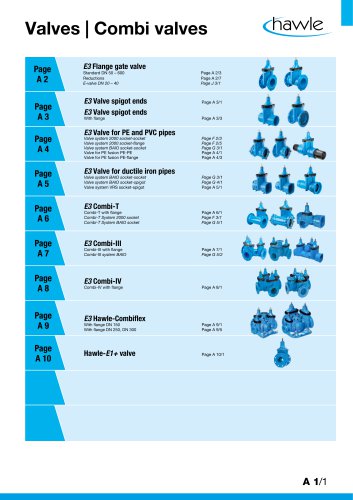

Valves | Combi valves_catalogue

40 Pages

-

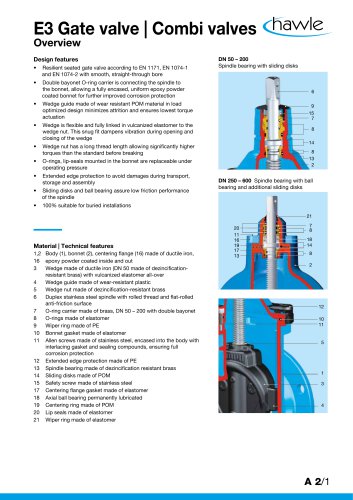

E3 Gate valve | Combi valves

5 Pages

-

Blue gold. Stop water loss now

24 Pages

-

Wastewater catalogue

72 Pages

-

Gas catalogue

44 Pages

-

Water Catalogue

333 Pages