Catalog excerpts

all measures in mm area A air hoseHV-cableprinting bloc with ions enriched field 1570 to 10070 to 100~ 30ְ20 - 50 (100)EI PSor EI VSionizedair streamproduct tobe printed RI 32, LS PLE orDA TR area B The most frequent problems with electrostatic charges in tampon print machines and their solutions > Ionizing systemProblemCauseSolution Dust or small particles are shown on the print. Fine paint splashes on the print. Fine paint splashes on the tampon while taking paint from the printing block. Dust or particles cling to the surface of the product to be printed and/or on the tampon caused by electrostatic charges.High electrostatic charges caused by deformation of the tampon by touching the product to be printed. While the tampon is slackening fine paint threads are torn out of the paint film and diverted by electrostatic field strength powers.High electrostatic charges caused by deformation of the tampon by touching the product to be printed. While the tampon is slackening fine paint threads are torn out of the paint film and diverted by electrostatic field strength powers. 2, 3 or 4 ring ionizers RI 32, 2 air gates LS LE or Delta blower DA TR depending on the size of the product to be printed. (see area B)2, 3 or 4 ring ionizers RI 32, 2 air gates LS LE or Delta blower DA TR depending on the size of the product to be printed. (see area B)1 ionizing bar type EI PS at right angles to the way the tampon moves, if the tampon is not lifted higher than 20 30 mm.1 ionizing bar type EI VS if the lifting distance is higher, due to its larger distribution area (see area A). Blow on the product to be printed and the tampon with ionized air just before and after the printing. The tampon must be consistently surrounded by ionized compressed air. Blow in the distance between tampon and product to be printed.Blow ionized compressed air gently and consistently from all sides around the tampon and the product to be printed.Discharge the tampon on its way to and from the printing bloc with an ionizing bar. ֕ՕՕՕ The tampon is charged electrostaticly while deforming and therefore draws up dust and fine particles. As this is the main element of interference the tampon must be air flown constantly while deforming or slackening. Ionized compressed air must be b 0.5 1.5 bar of compressed air is needed.Caused by electrostatic charges the product to be printed often has already drawn up dust and fine particles which must be eliminated with before the tampon contacts the product. As the paint would dry too fast it is recommended not to blow directly on the printing bloc. Only at a certain electrostatic charge paint splashes can be seen on the tampon while taking paint from the printing bloc.As electrostatic charges are build up gradually with each step of printing they can be controlled with the tampon passing a with ions enriched field either way (see illustration area A).Due to financial aspects it is recommended to control the compressed air flow via a magnetic valve or a pedal switch. With divergent tampon sizes or forms the device configuration is compiled with individual installation. lown in the distance between tampon and product to be printed. Both, the product to be printed and the tampon will therefore be discharged at the same time. Only a maximum ofa powerful compressed air blow (~ 4 ֖ 4.5 bar) General remarks: > Tampon print machines size="-4">

Open the catalog to page 1

tr.row {} td.cell {} div.block {} div.paragraph {} .font0 { font:19.00pt "Arial Black", sans-serif; } .font1 { font:12.00pt "Franklin Gothic Medium", sans-serif; } .font2 { font:6.00pt "Georgia", serif; } .font3 { font:4.00pt "Microsoft Sans Serif", sans-serif; } .font4 { font:6.00pt "Microsoft Sans Serif", sans-serif; } .font5 { font:8.00pt "Microsoft Sans Serif", sans-serif; } .font6 { font:12.00pt "Microsoft Sans Serif", sans-serif; } HAUG lonizing Systems -in tampon print machines m O i o Recommended ionizing Systems for diffrent tampon sizes Tampon size / form Area Ionizing system...

Open the catalog to page 2All HAUG catalogs and technical brochures

-

Ionizing unit NI

2 Pages

-

Ionizing unit LS GK

2 Pages

-

Ionizing unit EI VS

2 Pages

-

Ionizing unit EI VC

2 Pages

-

Ionizing unit EI RN

2 Pages

-

Ionizing unit EI SL

2 Pages

-

Power pack EN 9 Sine

2 Pages

-

Power pack Multistat Plus

2 Pages

-

Power pack Multistat

2 Pages

-

Air Line - Circle Cleaner 01

2 Pages

-

Ionizing unit AJ

2 Pages

-

Ionizing unit BI

2 Pages

-

IML - In Mould Labelling

1 Pages

-

Analytical weighing

4 Pages

-

Single cable technology

4 Pages

-

Clean room

2 Pages

-

Folding machines

2 Pages

-

Active ionizers

6 Pages

-

Counter electrodes

1 Pages

-

Bar holder

2 Pages

-

System X-2000

2 Pages

-

Cleaning systems RS 1 / RS 2

1 Pages

-

Perforation counter PZ 3

2 Pages

-

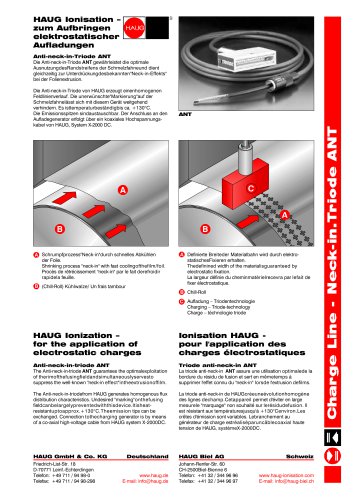

Anti-Neck-In-Triode ANT

2 Pages

-

Charging electrode ALW

1 Pages

-

Charging bar ALS

2 Pages

-

Statik-Air 09

2 Pages

-

Statik-Air 08

2 Pages

-

Ionizing air gun RI LG

2 Pages

-

Needle ionizer NI

2 Pages

-

Mini-Jet Ionisator MJ I

2 Pages

-

Air gate KL GK (Uno)

2 Pages

-

Ring ionizer EI RIF

2 Pages

-

Delta blower DA TR

2 Pages

-

Air Knife AK GK

2 Pages

-

One-Point-Ionizer OPI

2 Pages

-

Ionizing bar EI HRN

2 Pages

-

Segment-Ionisator EI Form

2 Pages

-

Power Pack EN 70 / EN 70 LC

2 Pages