Catalog excerpts

HAUG Ionization – for the elimination of electrostatic charges S-Line ionizing bar EI SL Thanks to its state-of-the-art ionization technology, the HAUG EI SL ionizing bar is setting new standards: Ensuring an optimal neutralizing effect, it eliminates electrostatic charges during roll, sheet and web processing (ill. 1 and 2). Special features and advantages The extensive development of the S-Line ionizing bar offers many advantages, especially to the application technology. • Modern tailor-made industrial design: The round construction of the ionizing bar, in combination with the special HAUG brackets (photo 1), permits the exact axial adjustment to the material web. The ionizing bar so always offers the optimal amount of positive and negative ions to the material to be neutralized. • Tailor-made technology: The outstanding HAUG engineering technology stands for high quality. This technology prevents disturbances as well as loss of production and produces a considerable saving of both time and expenses over the medium term. • Tailor-made accessories: The HAUG System X-2000 coaxial high-voltage plug connection offers unique benefits. The gastight high-voltage plug can be connected to HAUG power packs without tools. The flexible coaxially shielded cable is used to connect the ionizing bar to the voltage supply source (ill. 3 and 4). Passive ionizer The passive ionizer CI SL completes active ionizing units. It is an efficient pre-ionizer, especially for high charges. Passive ionizers are metallic pins which are connected to earth. When a passive ionizer is moved towards a charged material, an ion-producing corona discharge is induced in the pins of the ionizer. The neutralizing effect of a passive ionizer is particularly recommended in combination with an active ionizing unit. The passive ionizer works independently of power supply. Applications Today, HAUG ionizing bars are indispensable to the packaging, film/foil, printing and textile industries as well as for many other industrial applications. Recommendations The EI SL ionizing bar is suitable for feed speeds up to 100 m/min. S-Line ionization system The S-Line Power Pack EN SL provides the ionizer with approx. 7 – 8 kV alternating current by means of the integrated highvoltage transformer. The various ionizers are connected to the power pack. In order to ensure high efficiency and trouble-free production, we recommend that two ionizing bars be installed (above and below the material web. ill. 1), particularly during foil processing. The S-Line LC power pack comes with a signal lamp to monitor the high voltage. www.haug.de E-mail: info@haug.de Switzerland www.haug-ionisation.com E-mail: info@haug-

Open the catalog to page 1

Technical data EI SL Typen: length length length length length length length length length length length length length length length Order-No.: 03.8025.002 Order-No.: 03.8025.003 Order-No.: 03.8025.004 Order-No.: 03.8025.005 Order-No.: 03.8025.006 Order-No.: 03.8025.008 Order-No.: 03.8025.010 Order-No.: 03.8025.012 Order-No.: 03.8025.014 Order-No.: 03.8025.015 Order-No.: 03.8025.016 Order-No.: 03.8025.017 Order-No.: 03.8025.018 Order-No.: 03.8025.019 Order-No.: 03.8025.020 available from 150 to 2500 mm (total length) Standard bar lengths incl. high-voltage cable available ex-stock....

Open the catalog to page 2All HAUG catalogs and technical brochures

-

Ionizing unit NI

2 Pages

-

Ionizing unit LS GK

2 Pages

-

Ionizing unit EI VS

2 Pages

-

Ionizing unit EI VC

2 Pages

-

Ionizing unit EI RN

2 Pages

-

Power pack EN 9 Sine

2 Pages

-

Power pack Multistat Plus

2 Pages

-

Power pack Multistat

2 Pages

-

Air Line - Circle Cleaner 01

2 Pages

-

Ionizing unit AJ

2 Pages

-

Ionizing unit BI

2 Pages

-

IML - In Mould Labelling

1 Pages

-

Analytical weighing

4 Pages

-

Single cable technology

4 Pages

-

Clean room

2 Pages

-

Tampon print

2 Pages

-

Folding machines

2 Pages

-

Active ionizers

6 Pages

-

Counter electrodes

1 Pages

-

Bar holder

2 Pages

-

System X-2000

2 Pages

-

Cleaning systems RS 1 / RS 2

1 Pages

-

Perforation counter PZ 3

2 Pages

-

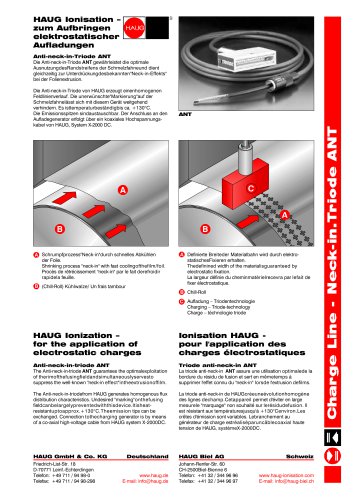

Anti-Neck-In-Triode ANT

2 Pages

-

Charging electrode ALW

1 Pages

-

Charging bar ALS

2 Pages

-

Statik-Air 09

2 Pages

-

Statik-Air 08

2 Pages

-

Ionizing air gun RI LG

2 Pages

-

Needle ionizer NI

2 Pages

-

Mini-Jet Ionisator MJ I

2 Pages

-

Air gate KL GK (Uno)

2 Pages

-

Ring ionizer EI RIF

2 Pages

-

Delta blower DA TR

2 Pages

-

Air Knife AK GK

2 Pages

-

One-Point-Ionizer OPI

2 Pages

-

Ionizing bar EI HRN

2 Pages

-

Segment-Ionisator EI Form

2 Pages

-

Power Pack EN 70 / EN 70 LC

2 Pages