Catalog excerpts

tr.row {} td.cell {} div.block {} div.paragraph {} .font0 { font:7.00pt "Arial", sans-serif; } .font1 { font:8.00pt "Arial Black", sans-serif; } .font2 { font:13.00pt "Arial Black", sans-serif; } HAUG lonization -for the limination of electrostatic charges Delta blower DA TR -Small design - great effectiveness Its compact design makes the Delta blower DA TR a very versatile device. Its wide, cone-shaped air jet blows across the ionizing pins which generate a vigorous ionic current with positive and negative ions. The Delta blower offers a whole range of applications in the most diverse fields. For example, it can be used to help separate sheets on paper or film sheet piles as well as to remove dust particles attached to surfaces. Advantages and benefits The precise air-assistance means that the effective distance can be increased to up to 100 mm from the material to be cleaned. The Delta blower is attached using a M6 threaded bolt attached to the housing. It is supplied with high voltage from a HAUG power pack. It is connected to the power pack using a highly flexible high-voltage cable (0 7.5 mm). These are some of the advantages of the Delta blower: prevents machine stops 镕 reduces material consumption improves removal processes Օ reduces malfunctions in assembly and distribution processes increases productivity DA TR HAUG lonization systems HAUG lonization systems consist of at least two components: Օ one power pack with an integrated high-voltage transformer one or more connected ionizing units such as the Delta blower DA TR, supplied by the power pack with a voltage of 7-8 kV~. Applications Օ Paper and printing industries Tampon and label printing Օ Electronics and assembly workplaces Vibrating conveyors Օ Packaging industry Semiconductor industry Օ Films and foils, fibres Granular materials Օ Dedusting Service station A service station is required in all installations to pretreat the air (compact filter control valve). Its function is to separate the oil and water content, and it also serves to regulate the operating pressure. For special applications, servive stations with ultrafine filters are available. ill. 1 Cleaning and maintenance Regular cleaning with HAUG special cleaning agent SRM 1 and the cleaning kit RS 1 ensures a consistently high effectiveness of the unit. SRM 1 HAUG GmbH & Co. KG Germany Friedrich-List-Str. 18 D-70771 Leinf.-Echterdingen Phone: +49 711 / 94 98-0 Telefax: +49 711 /94 98-298 HAUG Biel AG www.haug.de E-mail: info@haug.de Switzerland Johann-Renfer-Str. 60 CH-2500 Biel-Bienne 6 Phone: +41 32/344 96 96 Telefax: +41 32/344 96 97 www.haug-ionisation.com E-mail: info@haug-biel.ch

Open the catalog to page 1

tr.row {} td.cell {} div.block {} div.paragraph {} .font0 { font:6.00pt "Arial", sans-serif; } .font1 { font:7.00pt "Arial", sans-serif; } .font2 { font:8.00pt "Arial Black", sans-serif; } .font3 { font:41.00pt "Courier New", monospace; } .font4 { font:7.00pt "Georgia", serif; } Technical data Delta blower DA TR Type: DATR Order-No.: 04.7300.000 Dimensions: 85 x 21 x 52 mm (WxHxD) Nozzles: 14nozzles Weight: 110 g (without HV-cable, air hose) Air consumption: see table, depending on pressure Optimum effective distance: 20 - 300 mm Operating temperature: +5°C to +45 °C Storage/transport...

Open the catalog to page 2All HAUG catalogs and technical brochures

-

Ionizing unit NI

2 Pages

-

Ionizing unit LS GK

2 Pages

-

Ionizing unit EI VS

2 Pages

-

Ionizing unit EI VC

2 Pages

-

Ionizing unit EI RN

2 Pages

-

Ionizing unit EI SL

2 Pages

-

Power pack EN 9 Sine

2 Pages

-

Power pack Multistat Plus

2 Pages

-

Power pack Multistat

2 Pages

-

Air Line - Circle Cleaner 01

2 Pages

-

Ionizing unit AJ

2 Pages

-

Ionizing unit BI

2 Pages

-

IML - In Mould Labelling

1 Pages

-

Analytical weighing

4 Pages

-

Single cable technology

4 Pages

-

Clean room

2 Pages

-

Tampon print

2 Pages

-

Folding machines

2 Pages

-

Active ionizers

6 Pages

-

Counter electrodes

1 Pages

-

Bar holder

2 Pages

-

System X-2000

2 Pages

-

Cleaning systems RS 1 / RS 2

1 Pages

-

Perforation counter PZ 3

2 Pages

-

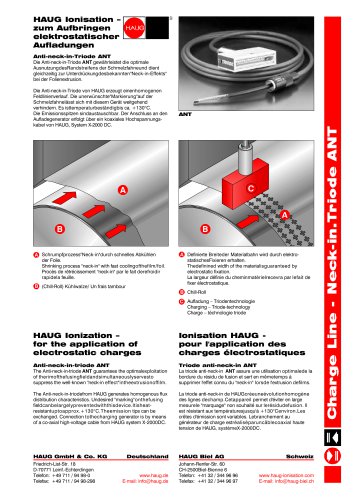

Anti-Neck-In-Triode ANT

2 Pages

-

Charging electrode ALW

1 Pages

-

Charging bar ALS

2 Pages

-

Statik-Air 09

2 Pages

-

Statik-Air 08

2 Pages

-

Ionizing air gun RI LG

2 Pages

-

Needle ionizer NI

2 Pages

-

Mini-Jet Ionisator MJ I

2 Pages

-

Air gate KL GK (Uno)

2 Pages

-

Ring ionizer EI RIF

2 Pages

-

Air Knife AK GK

2 Pages

-

One-Point-Ionizer OPI

2 Pages

-

Ionizing bar EI HRN

2 Pages

-

Segment-Ionisator EI Form

2 Pages

-

Power Pack EN 70 / EN 70 LC

2 Pages