Catalog excerpts

People | Power | Partnership >

Open the catalog to page 1

HARTING is committed to maintaining close proximity to markets and customers. Always at hand on location, HARTING is able to rapidly record market impulses and respond flexibly. HARTING is currently employing a workforce of more than 3000 members of staff worldwide.In todays increasingly knowledge and information shaped societies, the capability to network and integrate with customers and suppliers, as well as technology and business partners is playing the decisive role. And this applies to national as well as international levels. With 40 Subsidiary companies and Representatives in 27...

Open the catalog to page 2

HARTING Subsidiary company HARTING Representatives Increasing industrialization is creating growing markets characterized by widely diverging demands and requirements. The search for perfection, increasingly efficient processes and reliable technologies is a common factor in all sectors across the globe. > HARTING is providing these technologies in Europe, America and Asia. The > HARTING professionals at our international subsidiaries engage in close, partnership based interaction with our customers, right from the very early product development phases, in order to realize customer demands...

Open the catalog to page 3

practical solutions for its customers. Whether this involves industrial networks for manufacturing automation, or hybrid interface solutions for wireless telecommunication infrastructures, 3D circuit carriers with microstructures, or cable assemblies for high-temperature applications in the automotive industry - > HARTING technology pool, thereby enriching our resources. And every new solution we go on to create will draw on this wealth of resources in order to optimize each and every individual solution. In this way, > HARTING technologies offer far more than components, and represent...

Open the catalog to page 5

is the abbreviation for HAR TING- K atalog- I nformations- S ystem (HARTING catalogue information system). HARKIS > ή is an electronic catalogue with part configuration and 3D components library. Here you can choose a connector according to your demands. Afterwards you are able to send your inquiry created with the listed parts. The drawings to every single part are available in PDF-format. The parts are downloadable in 2D-format (DXF) and 3D-format (IGES, STEP). The 3D-models can be viewed with a VRML-viewer.You can find HARKIS > at www.HARKIS.HARTING.com . It is also available on CD-Rom...

Open the catalog to page 6

PICMG, formally known as the PCI Industrial Computing Manufacturing Group is an industry consortium of over 450 companies. PICMG֒s purpose is to define standard architectures in an effort to reduce system costs and development cycles and since its 1994 foundation, PICMG has been responsible for the establishment of several of successfully implemented, open, industrial standards. Open standards have proven themselves to be very advantageous for system manufacturers and end- user, because they create multiple vendors of similar parts, low prices at high volumes, and a shortened...

Open the catalog to page 8

AdvancedTCA carrier board with AdvancedMCΙ modules To connect AdvancedMC modules to carrier boards PICMG defined a new high-speed mezzanine connector: the AdvancedMCٙ connector a card edge connector mounted on the carrier board. It contacts directly with the module֒s PCB gold pads. Although PICMG defined four AdvancedMC connector types (B, B+, AB and A+B+), current market developments focus on type B+.The HARTING AdvancedMCٙ B+ connector features a new design element that supplements the standard the GuideSpring. The GuideSpring significantly increases the mating reliability and prevents...

Open the catalog to page 9

con: card + is a quality seal for AdvancedMC connectors that helps to deliver a significant increase in the reliability of MicroTCA > TM and AdvancedTCA > ٮ systems. In order to reach the target availability of 99.999 %, all system components must be carefully coordinated, and they must function reliably. The selection of suitable connectors is an essential, decisive factor here, as today it is virtually impossible for series production to meet the strict tolerances for the AdvancedMC con: card + philosophy. All the advantages are introduced in the following. Please find further information...

Open the catalog to page 10

con: card + connector. With years of experience in stamping techniques and the utilization of high-performance stamping tools with special process components, HARTING is actively involved in minimizing gold pad wear. > The specification for the AdvancedMC entails 200 mating cycles for a module. On the PCB, the nickel/hard gold layer on the relatively soft copper can only stand up to this high load if the contact surface is absolutely smooth. This is the case with the con: card + GuideSpring offsets these tolerance deviations by constantly pressing the module against the opposite wall. As...

Open the catalog to page 11

Design according PICMG AMC.0 (RoHS compliance) Materials Moulded parts Liquid Crystal Polymer (LCP), UL 94-V0Contacts Copper Alloy Contact surface Pd/Ni with Au flash Number of contacts 170 Contact spacing 0.75 mmClearance and creepage distance between contacts 0.1 mm min. Nominal differential impedance 100 Recommended plated through hole specification > ADrill hole-0.64 ر0.01 mm BCu25 - 35 mTin plated PCB (HAL)CSn5 - 15 յmDHole-0.53 - 0.60 mmAu / Ni plated PCBCNi3 - 7 صmAu0.05 - 0.12 mDHole-0.55 - 0.60 mmChemical tin plated PCBCSn0.8 - 1.5 mDHole-0.56 - 0.60 mmSilver plated PCBCAg0.1 -...

Open the catalog to page 12

Contact length [mm] No. of terminationIdentification contacts side Part number 170 2.0 16 04 170 5104 000 AdvancedMC connector for ATCA > ٮ , type B+ > with peg and with GuideSpring AdvancedMC connector for ATCA > ٮ , type B+ > 170 2.0 16 04 170 5106 000 without peg and with GuideSpring With pegWith peg Dimensions [mm] Without pegWithout peg > 1) fixing-hole optional2) non-metallized drillings3) recommended plated through hole specification see page 12 Board drillings (view magnified) > all holeskeep out area for press in bottom toolrow for ground

Open the catalog to page 13All HARTING catalogs and technical brochures

-

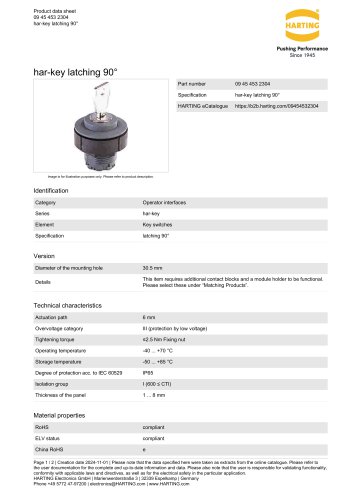

09 45 453 2304

2 Pages

-

09 45 453 2304

2 Pages

-

09 45 453 2202

2 Pages

-

Ha-VIS RFID4SMT

2 Pages

-

Ha-VIS eCon 2050GX-I-A

3 Pages

-

Ha-VIS eCon 3000

2 Pages

-

Han-Modular® Switch US4

2 Pages

-

STAF 6 STI-L

2 Pages

-

Han 3A-eg-QB-PG-13.5

2 Pages

-

SEK IDC Connectors

54 Pages

-

Subminiature D Connectors

200 Pages

-

Industrial Connectors Han®

52 Pages

-

livebook

10 Pages

-

HA-CheckOut® EK HE RL

2 Pages

-

M12 Magnetics

1 Pages

-

M8 D-coded PCB adapter

1 Pages

-

Han® Pneumatic Module Metal

2 Pages

-

Han-Modular® Sliding Frame

2 Pages

-

HARTING Device Connectivity_2016

896 Pages

-

HARTING Connectors DIN 41 612

230 Pages

-

Coaxial and Metric Connectors

128 Pages

-

HARTING Industrial Connectors han®

989 Pages

-

Ha-VIS RFID RF-R300 Reader

4 Pages

-

HARTING Component Range

40 Pages

-

HARTING News 2016

120 Pages

-

The Future needs the Past

11 Pages

-

HIS Catalogue

32 Pages

-

HIS Flyer

12 Pages

Archived catalogs

-

HARTING Device Connectivity

824 Pages

-

Industrial Connectors (Han®)

33 Pages