Website:

Hardinge Workholding

Website:

Hardinge Workholding

Group: HARDINGE

Catalog excerpts

CUSTOM WORKHOLDING SOLUTIONS PROVIDER >

Open the catalog to page 1

SPECIALS have been the choice of experienced machinists, manufacturing engineers and for- ward-thinking manufacturers around the world. SPECIALS . Design and Applications Engineers will work closely with you to solve your indi- vidual needs while working within your parameters. For generations, Hardinge Introducing a productivity and solu-tions guide for custom-manufactured workholding products. Over the next several pages youll see remedies to problems you may relate to, such as out-of-round parts, odd shapes, hard- to-grip materials, geometric bar stock, unusual or difficult process...

Open the catalog to page 2

TURNING Large Diameter Chucking Versatile Feed Fingers Counter Collets for Coil Feed Proper Grip of Extruded Shapes Low-cost Pick-off Alternatives Hydromat Quick-Change dromat > Large diameter (110mm) turning application on ANSI, JIS, DIN, and ISO spindle configurations on a standard chuck-style lathe. Hardinge Sure-Grip Mill thru end feed fingers accept a family of geometric bar stock sizes. A two-split design accepts stock in rectangular, square, hex and octagon with parallel flats of same dimension. Hardinge provides small diameter counter collets for Escomatic and other brand coil-feed...

Open the catalog to page 3

TURNING Shape-Compliant Chuck Gear Hobbing Interference Fit Grip without Distortion Bar Pushing, Loading, Feeding Threaded Order Hole Collets Swallow & Grip Deep Parts > Multiple gripping locations with independent travels solve the problem of maintaining high-accuracy OD and ID concentricitys on out-of-round and delicate parts. Exclusive to Hardinge CNC lathes. Ball cage design for interference-fit applications such as gear hobbing. Ex- tremely accurate centering of the gear with manual loading and unloading. Built-in force control safely grips delicate or thin wall materials with- out...

Open the catalog to page 4

TURNING Pinned Step Chuck Swiss Pick-off Bayonet Lock Over-the- O O v v e e r r t t he Collet Step-Down Adapters Angled or Zig-Zag Slots 2-Jaw Collet Shoulder Gripping > Dual-slotted collet with custom-shaped jaws provided maximum gripping force for this customer's part. The part is located against pins for exact part length control. The part will not move even when there is a variation in the chucking diameter. Pick-off collet designed with quick-change bayonet lock. A groove in the diameter is for the use of a tool to install the collet. Multiple slots (or large slots) and double angle...

Open the catalog to page 5

TURNING Micro Machining and Drilling Non-slip & non-marking Guide Bushings Eliminate Tool Interference Special-Shapes Step Chuck Fixture Plate SChk Miniature Collets > Special-shape collets and step chucks are used for extruded stock, or for precision cast parts and molded products.Special-shape feed fingers and guide bushings are also available. Small collets for making surgical and dental instru- ments, laboratory work, electronic and aerospace parts, clockmaking and jewelers. D, WW and 3C style collets available. 5C to small collet adapt-ers also available. Extended-nose collets feature...

Open the catalog to page 6

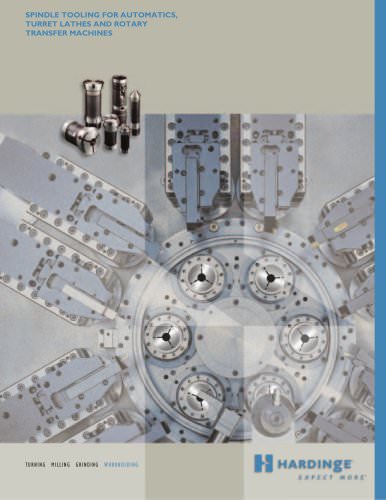

MILLING Eight Castings One Setup Tombstone-style Fixturing Pick & Place Tool Loss of Air - No Problem Large Run Angled Fixturing Multiple, Long Part Indexing Holder Automation > Mill odd-shape castings using a custom fixture setup. Hydraulic internal gripping application shown. Stock 5C or 16C collet blocks can be arranged and plumbed to your requirements. Pneumatic and hydraulic options are available. Collet blocks mount vertically or horizontally to hold single or multiple parts. 5C, 16C or 3J collet OD or ID gripping applications available. 5C Pneumatic Collet Block has fail-safe...

Open the catalog to page 7

Did you know that true 4th-axis is not neces- sary to accomplish spiral milling, but can be done using an RS-232 cable with the Hardinge Index- ing System? Ground pull stud snaps the tool holder in place in seconds! The Mach- 1 Tooling System reduces job setup and increases ac- curacy and repeatability. 16C collet-style adapter used in a Hardinge 16C indexer grips a VMC-type tool holder for boring, grooving and milling the flats. An internal assembly grips the retention knob on the back end of the part. Change the taper of your toolholder spindle with a Hardinge tool- holder adapter. 3CH to...

Open the catalog to page 8

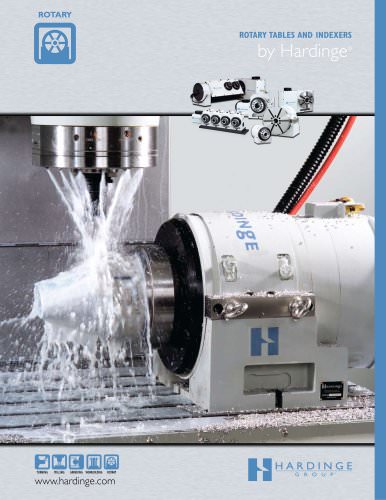

Hardinge manufactures a complete line of ROTARY PRODUCTS that can be customized for your applicaton: Milling Օ Turning Grinding Օ Measuring/InspectionGeneral precision and Super-Precision models can be configured with collets, step chucks, jaw chucks, magnetic chucks, slotted face plates or custom fixture plates. Grip on an OD, ID, or a special shape or taper. Customize a trunnion for multiple part positioning. MILLING Multiple Part Indexing Super-Precision > Super High-Speed & High Accuracy Positioning Device > Load up a trunnion with collet blocks, configure with clamping devices, or...

Open the catalog to page 9

GRINDING Adapt Work-head to use Collets Wheelhead Pinned Step Chuck Kellenberger > Double-head ColletΖ2x Grip Lens Grinding Collets 5C Adaptability > This collet grips a plug placed on the lens for ease of grinding and polishing of all surfaces. 1C, 2VB and other small collets are available from Hardinge to grip various size grinding wheels. Step chucks and pinned step chucks can provide faster changeover than a manual chuck. Steel pins can be ground to a desired stop location for part length control. Adapter sleeve required. Built-in A2-5 / MT5 workhead spindle accepts an array of standard...

Open the catalog to page 10

GRINDING Non-tapered Workheads Internal Gripping Fixture Plates Jig Grinding Collet Block Jig Grinder Spindle Adapters g G G r i i n d d er Valve Seater Grinding > Custom fixtures are smart solutions for high produc- tion facilities running the same part 24/7. A fixed loading position eliminates manual positioning and setup that would occur using a magnetic chuck. Collet sleeves and collets are available for non- tapered workheads in a bolt-on style. Expanding collets can be used with draw plugs in the workhead for internal gripping. Screw-in style offers quick-on, quick-off feature....

Open the catalog to page 11All Hardinge Workholding catalogs and technical brochures

-

Sure-Grip 3-Jaw Power Chucks

24 Pages

-

Workholding Product Overview

20 Pages

-

HQC® Quick-Change Collets

12 Pages

Archived catalogs

-

HCAC Collet Adaptation Chucks

28 Pages

-

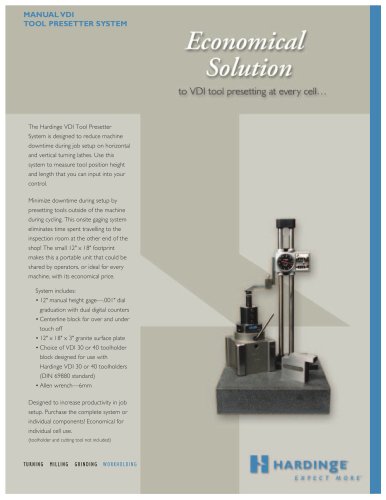

VDI Tool Presetter System

2 Pages

-

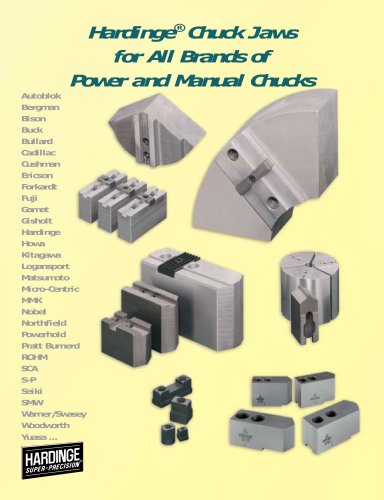

Hardinge® Chuck Jaws

32 Pages

-

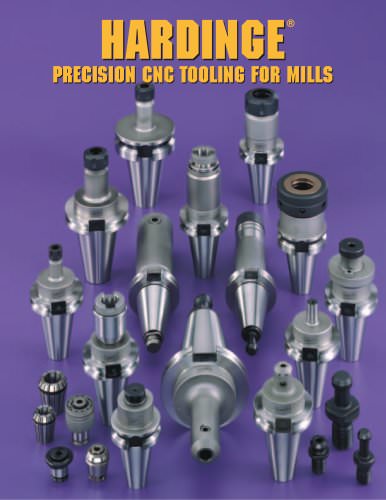

Precision CNC Tooling for Mills

48 Pages