Catalog excerpts

LINEAR ACTUATORS Encapsulated linear actuators up to 12,000 N

Open the catalog to page 1

moving As one of the leading manufacturers of electrical and electronic drive components and systems we offer you a wide product range for almost every industrial application in many different branches of industry. Innovative products and our sound technical competence have made us a reliable partner for more than 50 years. We understand our customers’ problems and find individual solutions. Accessories and safety from page 13 onwards

Open the catalog to page 2

ideas moving ideas – With this slogan we present ourselves on the market. It represents our aim to develop and produce modern and economic drive solutions for our customers. Our experience and orientation towards the future provide the foundations for our ambitious strategies. From our manufacturing sites in Germany as well as our international sales offices we deliver HANNING products and service to successful companies all over the world. universal and powerful Linear actuators for applications with protection class The encapsulated linear actuators of the SL 95, SL 80 and KL 95 series...

Open the catalog to page 3

Powerful and quick The range of HANNING encapsulated linear actuators is headed by the SL 95. It enables pressure and tension up to 12,000 N and traversing speeds up to 42 mm/s or 50 mm/s which almost remain constant even at rated load. The SL 95 linear actuators are ideal drives for a powerful and safe adjustment of therapy tables and many more medical and industrial applications. The reliable and rugged linear actuators can be adapted to the requirements regarding traversing speed and accuracy of position. Different stroke lengths are possible. They can be individually controlled by...

Open the catalog to page 4

Max. force (push) / max. force (pull) 12,000 N (industrial application) / on request 10,000 N (medical application) / on request Stroke length Duty time • pneumatically • electrically • via HANNING universal control units • via HANNING frequency inverters • via low-voltage switching elements • via standard SPS • End position limitation through internal micro-switch • Optionally the end positions can be externally limited by micro switches Position detection • Hall sensor Safety options • Declutching in downwards direction, special declutch bearing • HANNING safety-lock-box single phase

Open the catalog to page 5

z = Overlapping depends on load and stroke length H = Horizontal fork joint position, turned by 90° V = Vertical fork joint position, as shown

Open the catalog to page 6

Universal and compact The new SL 80 is very powerful and covers up to 8,000 N. Many new applications are possible. Its newly developed housing with integrated endshield ensures a very compact design. The SL 80 is now also suitable for smaller mounting spaces. The very rugged motors enable almost a load-constant speed up to 15 mm/s. As option, the SL 80 is also available with a declutch system. The power transmission can be interrupted in one direction so that the traversing in is only caused by the weight which is loaded on the drive. The declutching is achieved by interrupting the power...

Open the catalog to page 7

Max. force (push) / max. force (pull) Stroke length Duty time • pneumatically • electrically • via standard PLC • via HANNING universal control units • via low-voltage switching elements • via HANNING frequency inverters • End position limitation through internal micro-switch • Optionally the end positions can be externally limited by micro switches Position detection • Hall sensor Safety options • Declutching in downwards direction, motor disengaged • HANNING safety-lock-box

Open the catalog to page 8

(H) = Horizontal fork joint position, turned by 90° ® = Vertical fork joint position, as shown

Open the catalog to page 9

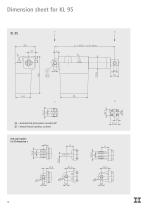

Small and individual The KL 95 is the smallest linear actuator of this series. Nevertheless it is as rugged as all the other drives. It is suitable for applications up to 4,000 N and traversing speeds of 18 mm/s. Of course, the linear actuators can be adapted to your individual application regarding power, traversing speed and accuracy of position. As option, the KL 95 is also available with a declutch system. The power transmission can be interrupted in one direction so that the traversing in is only caused by the weight which is loaded on the drive. The declutching is achieved by...

Open the catalog to page 10

Max. force (push) / max. force (pull) Stroke length Duty time • pneumatically • electrically • via standard PLC • via HANNING universal control units • low-voltage switching elements through SL 80 / SL 95 masters • Mechanical end position limitation • Optionally the end positions can be externally limited by micro switches Position detection • Hall sensor Safety options • Declutching in downwards direction, motor disengaged • HANNING safety-lock-box

Open the catalog to page 11

H = Horizontal fork joint position, turned by 90° V = Vertical fork joint position, as shown Fork joint option KL 95 dimension a

Open the catalog to page 12

To complete the drive system, HANNING offers an extensive range of accessories including different control variants, hand and foot switches. A drive can either be controlled through a HANNING pneumatic hand or foot switch or an electrical hand or foot switch in low-voltage technology. Furthermore it is possible to control a drive with an infra-red remote control and the CTRL universal control unit. This system includes a comfortable memory function which finds programmed positions directly. The switch design and the control type can be selected as desired. Control units HANNING offers...

Open the catalog to page 13

HANNING universal control unit CTRL HANNING’s frameless universal control unit is suitable for applications in very small mounting spaces and offers the user many control and safety options. All HANNNG linear actuators can be equipped with this type of control unit. Safety options • Enable input • Safety switch-off 5 V DC Analog keyboard Infra-red interface RECS80 Coded signal cable RECS80 Bus interface (in preparation) Error diagnostics Motor control • 4 x 0.5 kW single phase • Connection of up to four motors possible • Connection of up to three motors and two switching outputs possible •...

Open the catalog to page 14All HANNING catalogs and technical brochures

-

HAVENTIC

9 Pages

-

hatronic

11 Pages

-

HAMOTIC

11 Pages

-

Hot Air Application

2 Pages

-

Electronic around the motor

16 Pages

-

Frameless Motors

16 Pages

-

Industrial Motors

28 Pages

-

Compact Synchronous Drive

2 Pages

-

Compact Asynchronous Drive

20 Pages

-

S/SH 95, S/SH 80 and S/SH 56

24 Pages

-

hamatic lift

6 Pages

-

Linear actuator SI 95 / SHI 95

2 Pages

-

Linear actuator S 95 / SH 95

2 Pages

-

Linear actuator S 80 / SH 80

2 Pages

-

Linear actuator KL 95

2 Pages

-

Linear actuator SL 80

2 Pages

-

Linear Actuators SL 95

20 Pages

-

Circulatory pumps

8 Pages