Catalog excerpts

TECHNICAL CONSTRUCTION FILE (TCF) FILE NO DATE PRODUCT NAME: Digital Cutting Machine MODEL: BK, BK2, BK3, BKL, BKM, BKMS, GLK, LCP, SC, SCT, TK, TK3S, GLS, LCPS, PK, VK, TK4S, SK2 ACCORDING TO: MACHINERY DIRECTIVE: 2006/42/EC LOW VOLTAGE DIRECTIVE: 2014/35/EU ELECTROMAGNETIC COMPATIBILITY DIRECTIVE 2014/30/EU Hangzhou IECHO Science &Technology Co., Ltd No.1 Building, NO.1 Weiye Road, Binjiang District, Hangzhou city, Zhejiang Province, China.

Open the catalog to page 1

Content Part I General 1. 1.1 General description 2. 1.2 Product Parameter 3. 1.3 Quality control system 4. 1.4 List of applicable regulations and standards 1. 2.1 Essential health and safety requirements 2. 2.2 Risk assessment Part III Test report 1. 3.1 EN 12044 test report 2. 3.2 BS EN 60204-1 test report 3. 3.3 EN61000-6-3 & EN61000-6-1 Annex Technical Information 1. A.1 Declaration of conformity 2. A.2 Nameplate 3. A.3 Main parts list 4. A.4 Electrical circuit diagram 5. A.5 Original Instructions

Open the catalog to page 2

1.1 General description Basically, this kind of machine belongs to simple machine and with low risk when using it. All possible risk have been analysis in the risk assessment report and been prevent by suitable ways. In order to ensure the conformity for CE marking for these machines, some main European and/or International standards have been used to made assessment of conformity, they are EN 12044:2005+A1:2009. FOOTWEAR, LEATHER AND IMITATION LEATHER GOODS MANUFACTURING MACHINES. CUTTING AND PUNCHING MACHINES. SAFETY REQUIREMENTS. EN 60204-1:2018 SAFETY OF MACHINERY- ELECTRICAL EQUIPMENT...

Open the catalog to page 3

1.2 Product Parameter MODEL Cutting accuracy(mm) Data format Servo motor Media absorption Operation environment

Open the catalog to page 4

1.3 Quality control system In order to ensure the conformity of the series production, the HANGZHOU IECHO SCIENCE &TECHNOLOGY CO., LTD has taken the related procedures mentioned below 1 Carry out the inspection for parts and components according to the TCF Before the assemblies of the series production, the QC engineers of HANGZHOU IECHO SCIENCE &TECHNOLOGY CO., LTD has to check and inspect the technical specifications and intended functions of parts and components to ensure the correct use of them according to the contents of TCF and principle described in the related technical...

Open the catalog to page 5

1.5 List of applicable regulations and standards Directive: Machinery Safety directive: 2006/42/EC Low voltage directive: 2014/35/EU Electromagnetic Compatibility Directive 2014/30/Eu Standards: EN 12044:2005+A1:2009. FOOTWEAR, LEATHER AND IMITATION LEATHER GOODS MANUFACTURING MACHINES. CUTTING AND PUNCHING MACHINES. SAFETY REQUIREMENTS. EN 60204-1:2018 SAFETY OF MACHINERY- ELECTRICAL EQUIPMENT OF MACHINES PART 1: GENERAL REQUIREMENTS BS EN IEC 61000-6-1:2019 EN 61000-6-1:2019. ELECTROMAGNETIC COMPATIBILITY (EMC). GENERIC STANDARDS. IMMUNITY STANDARD FOR RESIDENTIAL, COMMERCIAL AND...

Open the catalog to page 6

2.1 Essential health and safety requirements relating to the design and construction of machinery 1. 1.1 1.1.1 1.1.2 Essential health and safety requirements P General remarks P Definitions P Principles of safety integration P (a) Machinery must be designed and constructed so These requirements have been P that it is fitted for its function, and can be operated, taken into account during the adjusted and maintained without putting persons at design of this machine. risk when these operations are carried out under the conditions foreseen but also taking into account any reasonably...

Open the catalog to page 8

Machinery must be supplied with integral lighting suitable for the operations concerned where the absence thereof is likely to cause a risk despite ambient lighting of normal intensity. Machinery must be designed and constructed so that there is no area of shadow likely to cause nuisance, that there is no irritating dazzle and that there are no dangerous stroboscopic effects on moving parts due to the lighting. Internal parts requiring frequent inspection and adjustment, and maintenance areas must be provided with appropriate lighting. Design of machinery to facilitate its handling P...

Open the catalog to page 9

exhaust gases and/or lack of oxygen. If the machinery is intended to be used in a hazardous environment presenting risks to the health and safety of the operator or if the machinery itself gives rise to a hazardous environment, adequate means must be provided to ensure that the operator has good working conditions and is protected against any foreseeable hazards. Where appropriate, the operating position must be fitted with an adequate cabin designed, constructed and/or equipped to fulfil the above requirements. The exit must allow rapid evacuation. Moreover, when applicable, an emergency...

Open the catalog to page 10

the machinery must fall or be ejected, — automatic or manual stopping of the moving parts, whatever they may be, must be unimpeded, — the protective devices must remain fully effective or give a stop command, — the safety-related parts of the control system must apply in a coherent way to the whole of an assembly of machinery and/or partly completed machinery. For cable-less control, an automatic stop must be P activated when correct control signals are not received, including loss of communication. Control devices P Control devices must be: P — clearly visible and identifiable, using...

Open the catalog to page 11

the use of one of them precludes the use of the others, except for stop controls and emergency stops. When machinery has two or more operating positions, each position must be provided with all the required control devices without the operators hindering or putting each other into a hazardous situation. Starting It must be possible to start machinery only by Devices preventing unintended P voluntary actuation of a control provided for the starting have been provided. purpose. The same requirement applies: P - when restarting the machinery after stoppage, P whatever the cause - when...

Open the catalog to page 12

machinery in which an emergency stop device would not lessen the risk, either because it would not reduce the stopping time or because it would not enable the special measures required to deal with the risk to be taken, portable hand-held and/or hand-guided machinery. The device must: have clearly identifiable, clearly visible and quickly accessible control devices, stop the hazardous process as quickly as possible, without creating additional risks, where necessary, trigger or permit the triggering of certain safeguard movements. Once active operation of the emergency stop device has...

Open the catalog to page 13All Hangzhou IECHO Science & Technology Company catalogs and technical brochures

-

iBrightCut Manual

78 Pages

-

IPlyCut User Manual

30 Pages

-

IMulCut V1 User Manual

27 Pages

-

CutterServer User Manual

42 Pages

-

ISO

1 Pages

-

CE

1 Pages

-

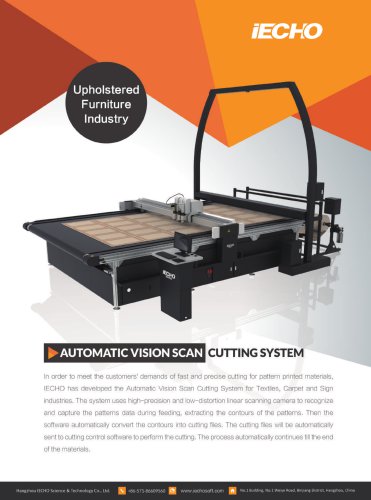

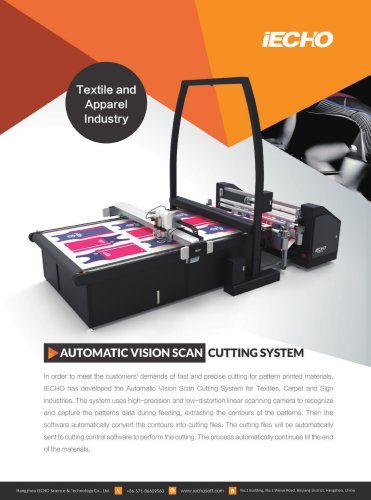

Textile and apparel industry

2 Pages

-

LCKS

4 Pages

-

PK1209 PRO & PK1209 PRO MAX

2 Pages