Catalog excerpts

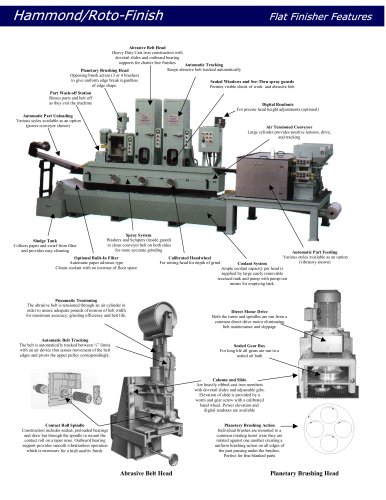

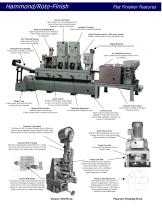

Flat Finisher Features Abrasive Belt Head Heavy Duty Cast iron construction with dovetail slides and outboard bearing supports for chatter free finishes Automatic Tracking Keeps abrasive belt tracked automatically Planetary Brushing Head Opposing brush action (3 or 4 brushes) to give uniform edge break regardless Sealed Windows and See-Thru spray guards of edge shape. Permits visible check of work and abrasive belt Part Wash-off Station Rinses parts and belt off as they exit the machine Digital Readouts For precise head height adjustments (optional) Automatic Part Unloading Various styles available as an option (power conveyor shown) Air Tensioned Conveyor Large cylinder provides positive tension, drive, and tracking Sludge Tank Collects paper and swarf from filter and provides easy cleaning Spray System Washers and Scrapers (inside guard) to clean conveyor belt on both sides for more accurate grinding Optional Built-In Filter Automatic paper advance type Cleans coolant with no increase of floor space Automatic Part Feeding Various styles available as an option (vibratory shown) Coolant System Ample coolant capacity per head is supplied by large easily removable recessed tank and pump with pump-out means for emptying tank. Calibrated Handwheel For setting head for depth of grind Pneumatic Tensioning The abrasive belt is tensioned through an air cylinder in order to assure adequate pounds of tension of belt width for maximum accuracy, grinding efficiency and belt life. Automatic Belt Tracking The belt is automatically tracked between ¼” limits with an air device that senses movement of the belt edges and pivots the upper pulley correspondingly. Direct Motor Drive Both the turret and spindles are run from a common direct drive motor eliminating belt maintenance and slippage Sealed Gear Box For long life all gears are run in a sealed oil bath Column and Slide Are heavily ribbed cast iron members with dovetail slides and adjustable gibs. Elevation of slide is provided by a worm and gear screw with a calibrated hand wheel. Power elevation and digital readouts are available Contact Roll Spindle Construction includes sealed, preloaded bearings and draw bar through the spindle to mount the contact roll on a taper nose. Outboard bearing support provides smooth vibrationless operation which is necessary for a high quality finish. Planetary Brushing Action Individual brushes are mounted to a common rotating turret were they are rotated against one another creating a uniform brushing action on all edges of the part passing under the brushes. Perfect for fine blanked parts Abrasive Belt Head Planetary Brushing Head

Open the catalog to page 1All Hammond Roto-Finish catalogs and technical brochures

-

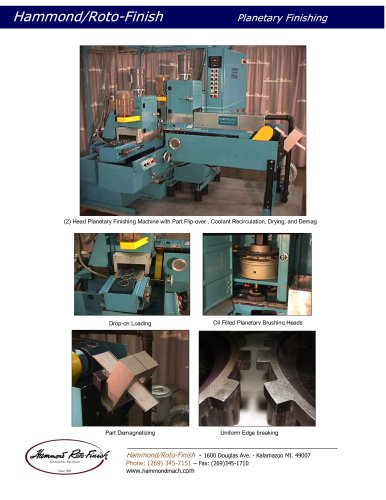

Planetary Finishing

1 Pages

-

Roto-Matic®

1 Pages

-

DUS KOLECTORS

1 Pages

-

Model CFD-60 Finishing Head

1 Pages

-

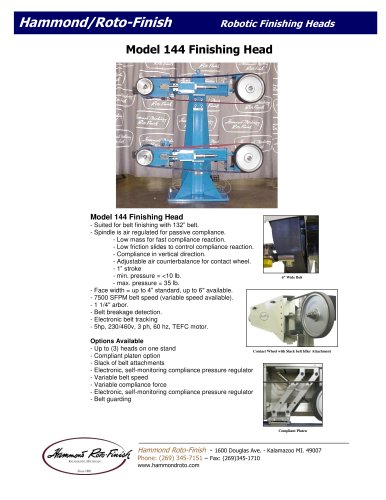

Model 144 Finishing Head

1 Pages

-

Flat Finishers

2 Pages

-

K-3000 Grinder

1 Pages

-

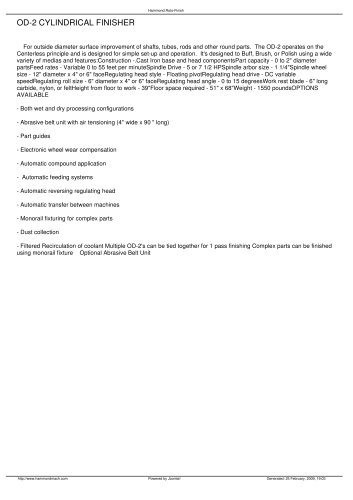

OD-2 CYLINDRICAL FINISHER

1 Pages

-

DUSKOLECTORS

4 Pages

-

Centrifugal Barrel

1 Pages