Catalog excerpts

Product Overview One-stop shop for quality and process control

Open the catalog to page 1

Product overview At Hammer-IMS we provide solutions to minimize material scrap, maximize product quality, reduce energy consumption, and achieve less labor-intensive operations. Our Marveloc-CURTAIN, Marveloc-CHARIOT and Marveloc-CIRCLE measuring systems are utilized for thickness and weight measurement, containing either fixed or moving sensor(s). Our Edge-Vision-4.0-CURTAIN machine-vision systems are used for the automated inspection and analysis of products in real-time during production. The three pillars of innovation Hammer-IMS innovates in three domains: mechanics, sustainable...

Open the catalog to page 2

OEM solutions In essence, all Hammer-IMS quality control systems can be ordered for integration into third-party machinery as part of an OEM project. Key in this regard is our programming API, which enables a third-party’s central computer system to control both third-party machinery and our Hammer-IMS system, displaying Hammer-IMS data and status on a single HMI. We offer this API through a number of industry-standard fieldbus protocols. Image of an M-Ray OEM Module. In an OEM application, the power and emergency stop buttons or switches should fit any relevant OEM customer policies and...

Open the catalog to page 3

SUSTAINABLE SENSOR TECHNOLOGY Marveloc is the brand name for our range of sensors that enable thickness and basis weight (grammage) control. Renowned for its high operational robustness and sustainability, Marveloc supports single and multi-sensor applications, allowing us to offer maximum material coverage. M-Ray: electromagnetic millimeter wave technology For thickness and basis weight (grammage) measurements The concept of our M-Ray technology for thickness or basis-weight (grammage) measurements is straightforward: A sensor at the top transmits an electromagnetic millimeter wave that...

Open the catalog to page 4

U-Ray: ultrasound sensor technology For battery film (coating) The U-Ray ultrasound sensors of Hammer-IMS are optimized for quality control of thinner materials and are able to penetrate metal materials or materials with high electrical conductivity such as carbon fibers or carbon sheets. The ultrasound U-Ray sensor was developed by upgrading analogue ultrasound sensing with digital signal processing techniques (DSP) to enable ultrasound wave phase and/or power detection. U-Ray sensors are ideal for solutions such as battery film applications, in which layer coated thickness needs to be...

Open the catalog to page 5

M2-Ray: radar-based sensor technology For thickness measurement of multi-layers and extruded pipes and profiles We have recently introduced our M2-Ray technology. The physical principle is comparable to the one of the M-Ray technology. Yet, with M2-Rays we are able to measure multilayers and extruded pipes and profiles. The M2-Ray technology can be mounted in a linear scanner or a circular scanner. The latter is particularly useful for pipe thickness measurement. Compatible with: CHARIOT, CIRCLE Sustainable and non-radioactive Marveloc technology It is no coincidence that we named our...

Open the catalog to page 6

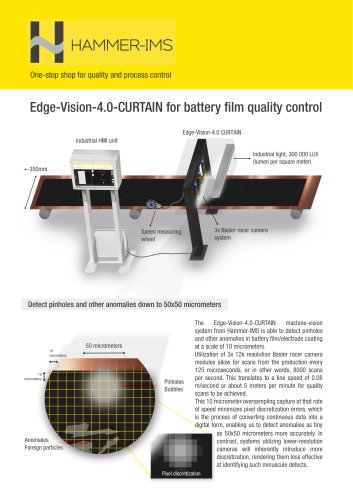

SUSTAINABLE VISION TECHNOLOGY Connected high-resolution optical inspection Our Edge-Vision-4.0 product family adds an extra eye to your product or process. We offer integrations of our Edge-Vision-4.0 technology mainly in CURTAIN frames, giving rise to Edge-Vision-4.0-CURTAIN systems. Edge-Vision-4.0 stands for optical ways to capture and analyze high-resolution images of your product or process. This is mainly done by means of machine-vision technology but can also be achieved by line laser technology or specialized color sensors. Our thickness measurement and basis-weight measuring...

Open the catalog to page 7

SUSTAINABLE VISION TECHNOLOGY Our newest AI-techniques for detection and classification As AI is increasingly on the rise, we are developing an AI-enabled feature, which distinguishes defects and classifies them into multiple defect categories. Based on a dataset of images, pre-classified by the customer, we use artificial intelligence to execute a learning process offline and build a powerful neural network for use during in-line quality control. When inspecting textile, plastic, or battery film in-line, the newly developed software continuously traces product defects and foreign items on...

Open the catalog to page 8

Mechanical platforms Our products consist of three variants: CURTAIN , CHARIOT and CIRCLE. Depending on the specific needs for your production or application, you might want to consider one, two or multiple variants. MECHANICAL PLATFORM Products equipped with a CURTAIN mechanical platform have sensors directly attached to the fixed or traveling mechanical frame. These systems are typically used for multi-sensor applications dealing with wider or thicker products. Scratch-free products, even for thick materials Your products deserve the best quality. When selecting the CURTAIN platform...

Open the catalog to page 9

MECHANICAL PLATFORM Scan to watch Vetex installation video Scan to watch Grandeco installation video Versatility and high compatibility When selecting the CURTAIN platform equipped with L-Ray technology for thickness measurement, stand-off distances can still be considerably high. The specific requirement for precision in the L-Ray system will dictate whether the stand-off distance results in a slight gap of a few millimeters (or mils)(applicable to our most precise thickness measurement L-Ray systems) or a larger gap of up to 20 centimeters (up to 7.9 inches) for less demanding...

Open the catalog to page 10

MECHANICAL PLATFORM The CHARIOT mechanical platform is perfectly suited for both new production lines or spacelimited retrofits for true-thickness measurement. By moving a single measuring head across the entire product width instead of the complete frame, the CHARIOT is cost and space efficient. Ideal for in-line thickness measurement Our compact system efficiently measures thicknesses with highprecision mode (material thickness up to 25 mm)(up to 0.9 inch) or extended-range mode (material thickness above 25 mm)(above 0.9 inch). The CHARIOT platform is equipped with our Marveloc sensor...

Open the catalog to page 11