Catalog excerpts

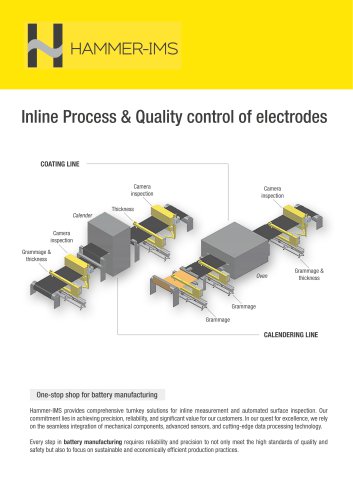

Inline Process & Quality control of electrodes COATING LINE Camera inspection Camera inspection Camera inspection Grammage & thickness Grammage & thickness Grammage Grammage CALENDERING LINE One-stop shop for battery manufacturing Hammer-IMS provides comprehensive turnkey solutions for inline measurement and automated surface inspection. Our commitment lies in achieving precision, reliability, and significant value for our customers. In our quest for excellence, we rely on the seamless integration of mechanical components, advanced sensors, and cutting-edge data processing technology. Every step in battery manufacturing requires reliability and precision to not only meet the high standards of quality and safety but also to focus on sustainable and economically efficient production practices.

Open the catalog to page 1

Inline Scanner, Marveloc-CURTAIN-C The Marveloc-CURTAIN-C scanner has been engineered to meet the exceptionally stringent requirements for thickness and basis weight measurement during the coating and calendering processes of electrodes. Its precision and reliability make it the ideal choice for demanding applications in electrode production. Wide range of scanners depending on your case A modular system is applicable for lines up to 1.400mm and offers you a wide range of measurement possibilities: • Thickness measurement with confocal laser technology. Accuracy down to 1 µm*. Coat weight...

Open the catalog to page 2

Camera inspection, Edge-Vision-4.0 To ensure the production of safe and sustainable batteries according to the strictest quality standards and achieve maximum operational efficiency, the integration of an optical inspection system becomes imperative. HammerIMS’s Edge-Vision-4.0 can proactively detect surface defects and continuously monitor surface characteristics and dimensions at every stage of electrode production. Hammer-IMS’s turnkey inspection solution will be designed and integrated to your individual needs. Edge-Vision-4.0 performs the following detection and monitoring tasks: •...

Open the catalog to page 3

Data management and Interfaces Data management in battery production is a crucial aspect of modern manufacturing processes ensuring top-quality control, process optimization, and traceability for product reliability, safety, and compliance. Hammer-IMS offers and implements a wide range of data interfaces: • Secure OPC UA integration for standardized data exchange. Powerful SQL database (Microsoft SQL) for data logging and analysis. Effortless FTP/SFTP file transfer for data sharing. Profile and Trend view of thickness measurement The BUS-INTERFACE-HUB brings the capability to establish...

Open the catalog to page 4All Hammer-IMS catalogs and technical brochures

-

Product Overview

20 Pages