Catalog excerpts

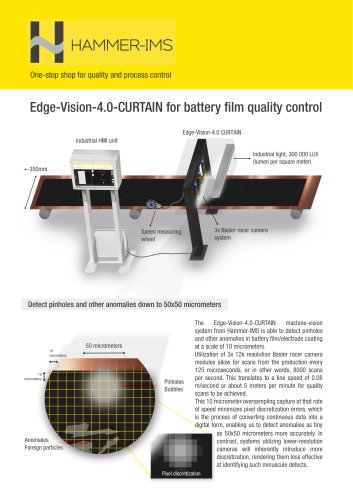

Edge-Vision-4.0-CURTAIN for battery film quality control Detect pinholes and other anomalies down to 50x50 micrometers The Edge-Vision-4.0-CURTAIN machine-vision system from Hammer-IMS is able to detect pinholes and other anomalies in battery film/electrode coating at a scale of 10 micrometers. Utilization of 3x 12k resolution Basler racer camera modules allow for scans from the production every 125 microseconds, or in other words, 8000 scans per second. This translates to a line speed of 0.08 m/second or about 5 meters per minute for quality scans to be achieved. This 10 micrometer oversampling capture at that rate of speed minimizes pixel discretization errors, which is the process of converting continuous data into a digital form, enabling us to detect anomalies as tiny as 50x50 micrometers more accurately. In contrast, systems utilizing lower-resolution cameras will inherently introduce more discretization, rendering them less effective at identifying such minuscule defects.

Open the catalog to page 1

Edge-to-edge analysis of material surface Edge-Vision-4.0-CURTAIN utilizes 3 image sensors that have an overlap zone of 2.5 cm between each camera. This allows us to stitch the three camera images into one image without losing any pixel. There is also a small margin of pixels that are scanned at both ends of the material being scanned, and this allows for EdgeVision-4.0 to have a safe margin in cases where the material shifts in cross-machine direction. -12k pixels x 3 image sensors = 36k pixel line scans -36k pixels / 350mm of material surface = full analysis of material surface. Equipped...

Open the catalog to page 2

Real-time analysis with Connectivity software 3.0 Thanks to Connectivity Software 3.0 by Hammer-IMS, real-time production analysis follows a streamlined process: detection of anomalies, classification of issues, counting/averaging for quality assessment, and action based on results. The PTP protocol ensures seamless integration of three image sensor feeds, leaving no part of the material unexamined. Optional FTP image-capture server uploads allow for later inspection or immediate adjustments. The images below to the left show the Connectivity Software 3.0 and a battery film coating being...

Open the catalog to page 3

Contact us to discuss your specific application The list below provides a general product overview of the Edge-Vision-4.0-CURTAIN systems and the software package for the control of it. An extensive list of add-ons can be implemented to your Edge-Vision-4.0-CURTAIN system on consultation with a sales representative. Product name Product group Product description Machine-vision systems Machine-vision solution for detection and classification of anomalies or continuous monitoring. Closed frame. Machine-vision systems Machine-vision solution for detection and classification of anomalies or...

Open the catalog to page 4All Hammer-IMS catalogs and technical brochures

-

Product Overview

20 Pages