Catalog excerpts

INSTALLATION INSTRUCTIONS INSTALLATION INSTRUCTIONS

Open the catalog to page 1

SCREWED BONNET NEEDLE VALVES H-99 / H-99HP H-900 SERIES RELIEF VALVES H-400 SERIES CHECK VALVES H900-HP SERIES HIGH PRESSURE RELIEF VALVES PIPE LINE PRECISION INSTRUMENTATION PIPE FITTING H-500 SERIES 3-Piece ball valves H600 SERIES T-TYPE & IN-LINE FILTERS H-700 SERIES BALL VALVES WITH LOCKING DEVICE PRESSURE GAUGES INSTALLATION & OPERATION INSTRUCTIONS H300U SERIES. Needle valves INSTALLATION INSTRUCTIONS LET-LOK TUBE FITTINGS 1/16" THROUGH - INCH 2 MM THROUGH 25 MM METRIC H-6800 SERIES INSTRUMENTATION BALL VALVES INSTALLATION INSTRUCTIONS

Open the catalog to page 2

through 1" - Inch, 2 mm through 25 mm - Metric LET-LOK® fittings are supplied assembled and finger tight. Diassembly before use can allow the entry of dirt or other particles. 1. Insert the tubing into the LET-LOK® fitting. Check that the tube rests firmly on the fitting shoulder and that the nut is finger tight. 2. Tighten the nut. 11/4 turns of the nut are required for 1/4" (6 mm) and higher. (See Figure A.) 3/4 of a turn of the nut is required for 3/16" (4 mm) and lower. (See Figure B.) Tube Cutter To attain a leak-free connection, cut the tubing squarely. Use a good quality tube cutter...

Open the catalog to page 3

Tube Cutting There are two ways to cut tubes: 1. Tube cutter 2. Hacksaw Tube Cutter ONE-LOK® fittings are supplied assembled and finger tight. Diassembly before use can allow the entry of dirt or other particles. 1. Insert the tubing into the ONE-LOK® fitting. Check that the tube rests firmly on the fitting shoulder and that the nut is finger tight. 2. Tighten the nut. 1 1/4 turns of the nut are required. (See Figure A.) To attain a leak-free connection, cut the tubing squarely. Use a good quality tube cutter with the appropriate blade for the tubing. Do not try to reduce the time of...

Open the catalog to page 4

HAM-LET PRECISION INSTRUMENTATION PIPE FITTINGS To ensure a leak-tight seal, HAM-LET recommends that you use a pipe-thread sealant on all NPT threads. The most effective sealing method is PTFE tape. Tape should be used only on male tapered pipe threads. Do not use tape on flared, coned or tube fitting ends! Note: We suggest two wraps for stainless-steel tapered pipe threads. Make sure the tape does not overhang the first thread. Otherwise,the tape could shred and enter the fluid system. Cut off excess tape. The connection is now ready for proper makeup. Clean both male and female tapered...

Open the catalog to page 5

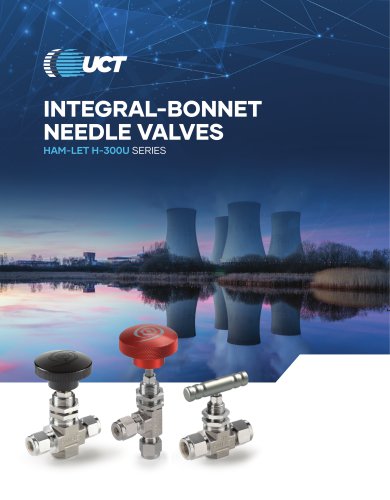

NEEDLE VALVES H-300U SERIES 1. Use For maximum valve life, use the valve only within the stated pressure and temperature range, and in accordance with the corrosion resistance of the material. Re-Assembly Reverse the steps above, taking care to lubricate all parts with an appropriate lubricant. 2. Operation To open the valve, rotate the handle until it comes in contact with the lower gland. This will allow maximum flow through the valve. To close the valve, rotate the handle until the stem tip comes into contact with the seat. Do not use excessive force when closing the valve. Excessive...

Open the catalog to page 6

SCREWED BONNET NEEDLE VALVES H-99 6. Installation Disassembly n On taper threads, use a conventional thread sealant such as PTFE tape or an appropriate alternative that is compatible with the application. n Apply a wrench to the body and connecting nut. Do not use the handle to tighten the connection. LET-LOK® Valves n Ensure the tubing is cut square and that it is de-burred. n Ensure the tubing is located firmly in the connection. n From the finger-tight position, rotate the nut a full 1 1/4 turn. Note: For sizes 3/16 inch (4mm) or less, rotate the nut 3/4 turn only. n Apply a wrench to...

Open the catalog to page 7

H-400 SERIES CHECK VALVES 1. Use For maximum valve life, use the valve only within the stated pressure and temperature range, and in accordance with the corrosion resistance of the material. Give particular attention to the compatibility of the O-ring material. 2. Disassembling and Cleaning the Valve A non-return valve can trap fluids within the body. If the valve has been used in hazardous media service, remove with great care and take appropriate decontamination measures. All persons involved in the removal and disassembly of the valve should wear proper protective clothing, such as...

Open the catalog to page 8

H-500 SERIES 3-PIECE BALL VALVES 2. Manual Operation 2.1 To open or close the valve, turn the handle 1/4 of a turn (90 degrees). A. When the valve is in the Open Position, the handle is parallel (in-line) with the valve or pipeline. B. When the the valve is in the Closed Position, the handle is perpendicular (crossed) to the valve or pipeline. 3. Automated Operation 3.1 Check any valve with an actuator for valve-stem alignment. Angular or linear misalignment will result in high operational torque and unnecessary wear on the stem seal. 4. Disassembling & Cleaning of the Valve: A ball valve...

Open the catalog to page 9

H-500 SERIES 3-PIECE BALL VALVES 6. General Information for On-Site Installation: 6.1 The valve may be fitted in any position on the pipeline. 6.2 To prevent damage to the seats and ball surface, make sure the pipeline is flushed, free of dirt, burrs and welding residues before installing the valve. INSTALLATION INSTRUCTIONS 7. Installation of Threaded Valves 7.1 Use a conventional sealant, such as a hemp core, PTFE, etc. 7.2 Apply a wrench to the hexagon end of the valve only. Tightening by using the valve body or handle can seriously damage the valve. 7.3 For applications where the...

Open the catalog to page 10

H-700 SERIES BALL VALVES WITH LOCKING DEVICE 1. Use For maximum valve life, use the valve only within the stated pressure and temperature range, and in accordance with the corrosion resistance of the material. 2. Operation To open or close the valve, turn the handle 1/4 of a turn (90°). 3. Cleaning the Valve A ball valve can trap fluids in the ball cavity when it is in the closed position. If the valve has been used in the hazardous medium, decontaminate it before disassembly. All persons involved in the removal and disassembly of the valve should wear appropriate protective clothing, such...

Open the catalog to page 11All HAM-LET catalogs and technical brochures

-

Relief Valves H-900 Series

5 Pages

-

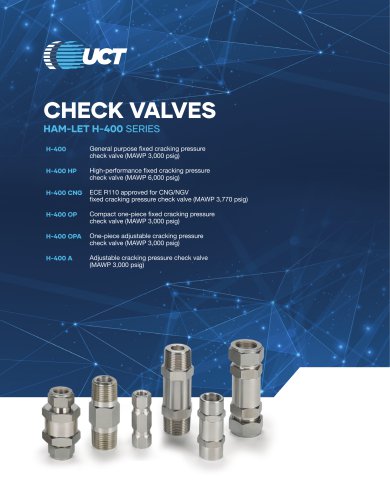

Check Valves H-400 Series

18 Pages

-

Pressure Gauges

31 Pages

-

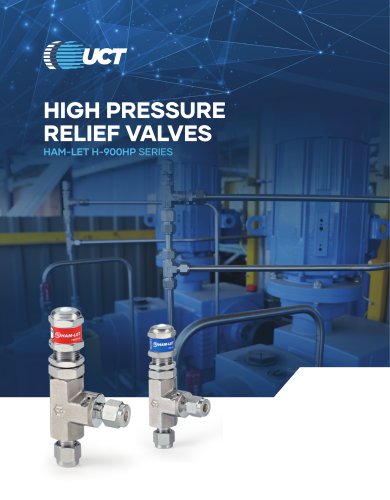

High Pressure

26 Pages

-

Quick Connector

8 Pages

-

Pressure Regulator

76 Pages

-

H1200 Toggle Valves

4 Pages

-

37° Flare Fittings

22 Pages

-

solar energy

4 Pages

-

Product at a glance

2 Pages

-

TOGGLE VALVES H-1200

4 Pages

-

Let-Lok® Tube Fittings

94 Pages

-

HTC - Hi-Tech Components

32 Pages

-

2015 CATALOG EN

517 Pages

-

HAM-LET HOSE CONNECTORS

4 Pages

-

ULTRA FAST DIAPHRAGM VALVE

6 Pages

-

VENT PROTECTOR FITTINGS VEP

2 Pages

-

HAM-LET FLANGE ADAPTERS

4 Pages

-

SAMPLE CYLINDERS

4 Pages

-

HAM-LET Hoses

24 Pages

-

Ham-Let Astava Line of Manifolds

26 Pages

-

UCV Ultra Clean Diaphragm Valves

22 Pages

Archived catalogs

-

H800 - Compact Ball Valves

8 Pages

-

Accessories

5 Pages