Website:

HAIDA EQUIPMENT CO., LTD

Website:

HAIDA EQUIPMENT CO., LTD

Catalog excerpts

About the Importance of Car Seat Slide Testing There are many types of cars now, but everyone's requirements for cars are becoming more and more strict, and testing is also indispensable for product safety. Among them, the slide rail of the car seat is also inevitable. The car seat slides in cars can be divided into manual slides and electric slides according to the driving method. According to the unlocking classification, they can be divided into built-in unlocking manual slides and external unlocking manual slides. According to the strength, they can be divided into low, medium, and For the advanced three columns, refer to the custom-made slide rail durability performance test bench in Clause 4.2.12 of "QCT 805-2008 Technical Conditions for Slide Rails for Passenger Car Seats" to test the durability performance of the slide rails and determine the rationality of product design . The following is mainly the importance and analysis of car seat slides.

Open the catalog to page 1

The lower anchor point of the seat belt of the front seat of the passenger car is at the rear end of the slide rail on the side of the seat aisle. Now the pre-tensioning end of the seat belt of many models is on the slide rail on the side of the seat door, and the lock of the slide rail The locking device is also a safety feature to ensure that the driver and passengers are safely locked when the vehicle fails. Therefore, the slide rail is also very important. The material of the slide rail must have safety characteristics, so that the slide rail reaches sufficient strength to protect the...

Open the catalog to page 2

Haida Instrument HD-YQ08-1 Car Seat Slide Rail Durability Test Bench The slide rail is the part of the whole chair connected to the body. The design of the base has 2 dimensions (achieved according to the front and rear adjustment of the slide rail), 4 dimensions (front and rear, up and down), 6 dimensions (front and rear, up and down, inclination), etc. The connection methods are also different. Of course there should be seat belt buckles etc.

Open the catalog to page 3

Because of the connection characteristics, it supports the driver and passengers. According to GB or DIN standards, there are different grades of human quality. For example 50kg, 75kg, 98kg and so on. The front and rear adjustment of the slide rail is a common function of the seat. The adjustment accuracy of the slide rails of different companies is also different, because the design of the locking mechanism is different. The front and rear adjustment range of the slide rail will affect the front and rear position of the H point of the seat, and the H point of the vehicle platform requires...

Open the catalog to page 4

Haida Instrument HD-YQ08-1 Car Seat Slide Rail Durability Test Bench Among them, riveting is also a common process for slide rails. For some monorails, the positioning pins need to be riveted on the body

Open the catalog to page 5

position, and some need to punch riveted screws to connect the seat cushion. There are also seat cushion connectors or seat belt brackets riveted to the monorail. The finished slide rail is also subjected to the tensile failure test of the riveted joint according to the national standard QCT 805-2008.

Open the catalog to page 6All HAIDA EQUIPMENT CO. catalogs and technical brochures

-

WEPACK ASEAN 2024

1 Pages

-

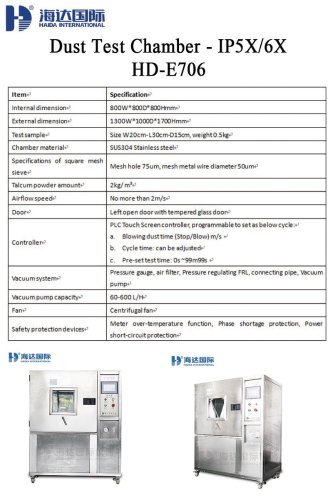

HD-E706 dust test chamber

1 Pages

-

No cross colored winter

1 Pages

-

How's your express?

4 Pages

-

Hardness Tester

2 Pages

-

How to select chairs

1 Pages

-

Salt Spray Chamber

5 Pages

-

Mid-Autumn Festival

2 Pages

-

How to choose summer clothes

3 Pages

-

Fabric Breathability Tester

2 Pages

-

IP ratings

2 Pages

-

Safety shoes

2 Pages

-

Battery test UN38.3

1 Pages

-

Radiation & UV Test Chambers

2 Pages

-

Non-stick Coating Tester

2 Pages

-

Solar Xenon Aging Test

2 Pages

-

Optical instrument

2 Pages

-

Sock Test Machines

12 Pages

-

furniture testing

2 Pages

-

Salt spray test chamber

1 Pages

-

waterproof level

2 Pages

-

carton tester

7 Pages

-

Drop Tester

3 Pages

-

WHAT IS ISTA

2 Pages

-

Salt Spray Chamber

4 Pages

-

Environment test chamber

2 Pages

-

Mechanical Transmission

2 Pages

-

Packaging test HD-A501-800

2 Pages

-

Zero Drop Tester

4 Pages

-

stroller handle tester

2 Pages

-

Battery Test

6 Pages

-

Lighting Test

1 Pages

-

Thermal shock test series

1 Pages

-

Office Chair testing machine

3 Pages

-

Needle Detector 2022

1 Pages

-

Aging Test Chamber series

1 Pages

-

Image Measuring Machine

1 Pages

-

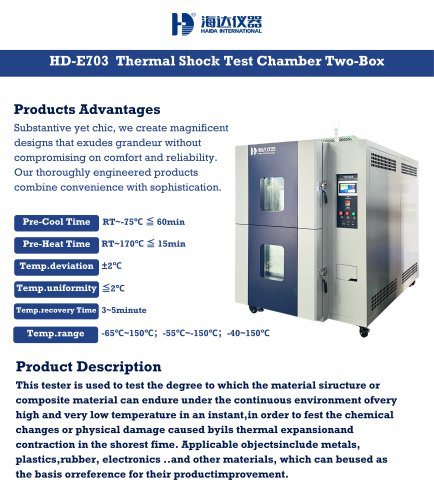

HD-E703

1 Pages

-

Tape Tester

1 Pages

-

History

1 Pages

-

Electro-dynamic shaker

1 Pages

-

Drop Test Machine

1 Pages

-

Inclined Impact Test Machine

1 Pages

-

Clamp Force Test Machine

1 Pages

-

Paper Printing Tester Series

1 Pages

-

HD - A815

1 Pages

-

HD - A519

1 Pages

-

UV Weathering Test Chamber

1 Pages

-

Salt Spray Chamber HD-E808

1 Pages

-

Ozone Aging Test Chamber

1 Pages

-

Dust Test Chamber IP5X6X

1 Pages

-

Dust Test Chamber

1 Pages

-

Vehicle Rain Test Rom

1 Pages

-

Thermal Shock Test Chamber

1 Pages

-

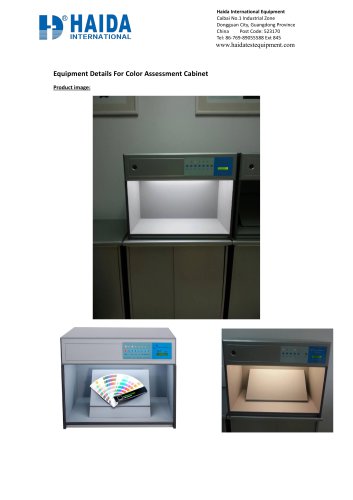

Color assessment cabinet

1 Pages

-

Desktop Tensile Test Machine

1 Pages

-

Finished Shoe Flexing Tester

1 Pages

-

Vibration Tester Machine

1 Pages

-

Chair Swivel Tester

1 Pages

-

Stroller Crash Test

1 Pages

-

HD-E808-60

1 Pages

-

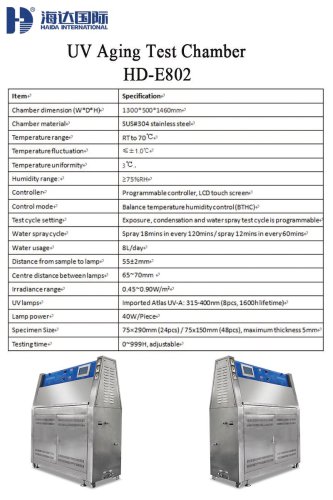

HD-E802

1 Pages

-

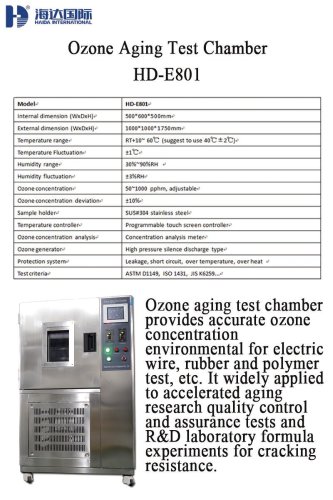

HD-E801

1 Pages

-

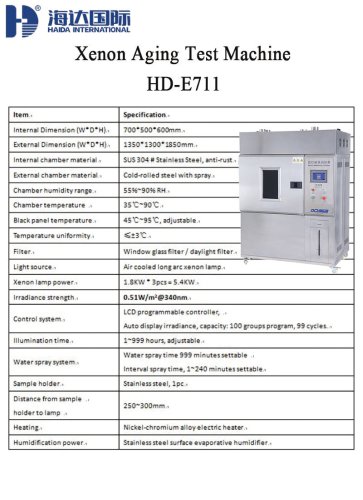

HD-E8711

1 Pages

-

HD-E710-4

1 Pages

-

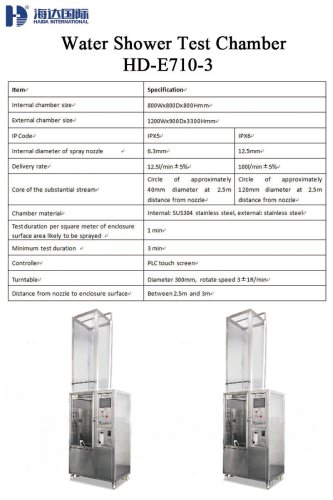

HD-E710-3

1 Pages

-

HD-E706

1 Pages

-

Fabric Tensile Tester

1 Pages

-

Leather Flexing Tester

1 Pages

-

Vibration Test Machine

1 Pages

-

Clamp Force Test Machine

1 Pages

-

Corrosion Resistance Tester

1 Pages

-

Chair Strength Tester

1 Pages

-

Chair Swivel Tester

1 Pages

-

HD-808-60

1 Pages

-

Walk-in Chamber

1 Pages

-

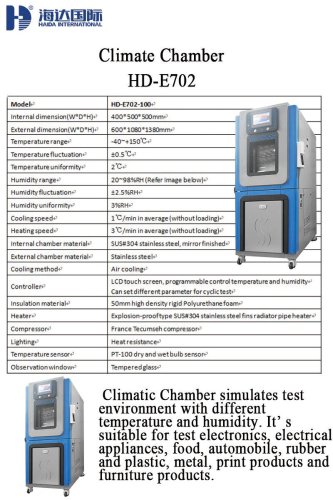

HD-E702

1 Pages

-

UV Aging Test Chamber

1 Pages

-

HD-E801

1 Pages

-

Xenon Aging Test Machine

1 Pages

-

HD-E704

1 Pages

-

HD-B607-S

1 Pages

-

Peel Test Machine

1 Pages

-

HD -B609B-S

1 Pages

-

HD-B609

1 Pages

-

walk in test chamber factory

1 Pages

-

HD-E705 Walk-in Chamber

1 Pages

-

HD-E702-225 Climatic Chamber

1 Pages

-

Handle Fatigue Tester

1 Pages

-

Eid al Adha

1 Pages

-

HD-F736 Chair Drop Tester

1 Pages

-

Visting Customers

1 Pages

-

Furniture Fair

1 Pages

-

DeliveBest Testing

1 Pages

-

HD-B616 Tensile Tester

1 Pages

-

HD-A520-3 Drop Test Machine

1 Pages

-

HD-B617-S Tensile Tester

1 Pages

-

Compression test machine

1 Pages

-

Mattress Roll Tester

1 Pages

-

Bevel Impact Testing Machine

1 Pages

-

Furniture Testing Machine

1 Pages

-

Tape testing machine

1 Pages

-

HD-E808-200

1 Pages

-

HAIDA EXHIBITION

1 Pages

-

Chair Swivel Tester

1 Pages

-

Hot and Cold impact tester

1 Pages

-

What is haida's mission?

1 Pages

-

China.Shanghai.SNIEC

1 Pages

-

test equipement

1 Pages

-

ISTA Products

1 Pages

-

sofa Durability Tester

1 Pages

-

Tensile Test Machine

1 Pages

-

Shake Vibration Test Machine

1 Pages

-

Furniture Testing Instrument

1 Pages

-

Tire Friction Test Machine

1 Pages

-

Caster Durability Tester

1 Pages

-

TENSILE TESTING MACHIME

1 Pages

-

ISTA Package Testing Machine

1 Pages

-

CARTON COMPRESSION TESTER

1 Pages

-

TENSILE STRENGTH TESTER

1 Pages

-

VIBRATION TEST SYSTEM

1 Pages

-

Altitude Test Chamber

1 Pages

-

BIOCHEMICAL INCUBATOR

1 Pages

-

SALT SPRAY CORROSION CHAMBER

1 Pages

-

WATER DRIP TEST CHAMBER

1 Pages

-

Foam compression Hardness

1 Pages

-

Universal Testing Machine

1 Pages

-

BURSTING TEST MACHINE

1 Pages

-

Temperature Humidity Chamber

1 Pages

-

Water conseryation

1 Pages

-

2019 ELECTRONICA CHINA

1 Pages

-

ISTA MEMBER

1 Pages

-

Thermal Shock Test Chamber

1 Pages

-

BOX CPMPRESSION TESTER

1 Pages

-

Sofa Test Equipment

1 Pages

-

CLIMATE TEST CHAMBER

1 Pages

-

BURSTING STRENGTH TTESTER

1 Pages

-

UTIVERSAL TESTING MACHINES

1 Pages

-

merry christmas

1 Pages

-

Thanksgiving Day

1 Pages

-

Chair Arm Tester

1 Pages

-

Chair Drop impact tester

1 Pages

-

Bursting Strength Tester

1 Pages

-

Vision Measuring Machine

1 Pages

-

vacuum drying oven

1 Pages

-

Formaldehyde test chamber

1 Pages

-

Product Description

1 Pages

-

Chair seat combined tester

1 Pages

-

Furniture test machine

1 Pages

-

force test machine

1 Pages

-

Catalog

1 Pages

-

Tensile tester

1 Pages

-

Chair Swivel Test Rig

5 Pages

-

Attitude Test Chamber

3 Pages

-

Cyclic Salt Spray Chamber

6 Pages

-

Contact angle measurement

3 Pages

-

ROHS test machine

4 Pages

-

Chair universal test machine

1 Pages

-

MIT folding endurance tester

2 Pages

-

Formaldehyde testing machine

1 Pages

-

HD-B615

1 Pages

-

HD-E702

1 Pages

-

HD-703

1 Pages

-

HD-E704

1 Pages

-

Tensile tester's User Manual

49 Pages

-

RUBBING FASTNESS TESTER FOR

3 Pages

-

ELMENDORF TEARING TESTER

4 Pages

-

COLOUR FASTNESS TO WASHING

3 Pages

-

IRONING SUBLIMATION COLOR

2 Pages

-

AUTOMATIC HYDRAULIC DIAPHRAM

5 Pages

-

SPRAY RATE TESTER

3 Pages

-

THERMAL SHOCK TEST CHAMBER

1 Pages

-

BICYCLE TEST MACHINE

11 Pages

-

AIR PERMEABILITY TESTER

5 Pages

-

NEEDLE DETECTOR

2 Pages

-

HD-E702-150-7

4 Pages

-

pull tensile testing machine

7 Pages

-

Thermal Shock Chamber

4 Pages

-

HD-J802 Sharp Edge Tester

11 Pages

-

ring test machine

9 Pages

-

Tensile Testing Machine

12 Pages

-

computer peel test machine

1 Pages

-

Incline Impact tester

1 Pages

-

paper testing machine

1 Pages

-

paper test machine

1 Pages

-

tensile testing machine

1 Pages

-

Gas chromatograph

1 Pages

-

coating machine

1 Pages

-

heat seal tester

1 Pages

-

coordinate measuring machine

1 Pages

-

Image measuring machine

1 Pages

-

chair base static tester

1 Pages

-

chair strength tester

1 Pages

-

chair stability tester

1 Pages

-

zigzag spring tester

1 Pages

-

corrosion resistance tester

1 Pages

-

chair durability tester

1 Pages

-

tensile tester

13 Pages

-

drying oven

1 Pages

-

paper testing information

12 Pages

-

BIFMA Furnitures testing machine

20 Pages

-

UV Aging Test Chamber

1 Pages

-

sand dust proof chamber

1 Pages

-

Cookware testing proposal

5 Pages

Archived catalogs

-

Foam rebound tester

2 Pages

-

Optical instrument HD SERIES

2 Pages

-

salt spray test HD-E808

9 Pages

-

Foam rebound tester 2022

1 Pages

-

Zero Drop Test Machine

1 Pages

-

Water Shower Test Chamber

1 Pages

-

HD -B617S

1 Pages

-

HD -B617

1 Pages

-

HD-B615A- S

1 Pages

-

HD-B609B-S

1 Pages

-

HD-B609

1 Pages

-

Chair Drop Test Rig_HD-F736

1 Pages

-

HD-B617-S

1 Pages

-

HD -B617

1 Pages

-

HD-B616-S

1 Pages

-

HB-B616

1 Pages

-

HB-B615A-S

1 Pages

-

HB-B609D

1 Pages

-

HB-B609B-S

1 Pages

-

HB-B609A-S

1 Pages

-

HB-B609

1 Pages

-

HB-B607-S

1 Pages

-

HD -B604 -S

1 Pages

-

HB-B604B-S

1 Pages

-

HB-B602

1 Pages

-

HD-B601

1 Pages

-

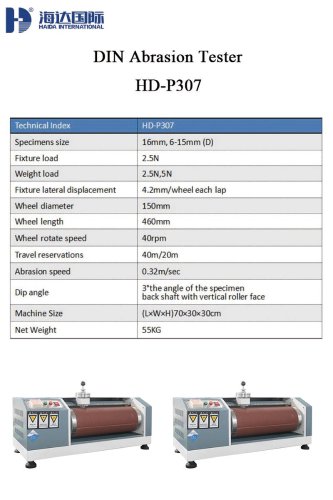

DIN Abrasion Tester_HD-P307

1 Pages

-

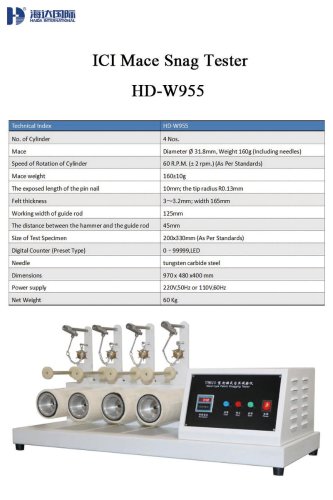

ICI Mace Snag Tester_HD-W955

1 Pages

-

Shoe Flexing Tester_HD-P802

1 Pages

-

Foam Rebound Tester_HD-F754

1 Pages

-

Foam Fatigue Tester

1 Pages

-

Chair Base Tester_HD-F733

1 Pages

-

HD -E706 Dust Test Chamber

1 Pages

-

HB-B617-S

1 Pages

-

HD -B617

1 Pages

-

HD-B616-S

1 Pages

-

HD-B615A-S

1 Pages

-

HD-B609A-S

1 Pages

-

HB-B604B-S

1 Pages

-

HD-E706 Dust Chamber_2018

3 Pages

-

Clamp Force Test Machine

9 Pages

-

sofa durability tester

1 Pages

-

chair swivel tester

1 Pages

-

biochemical incubator

1 Pages