Catalog excerpts

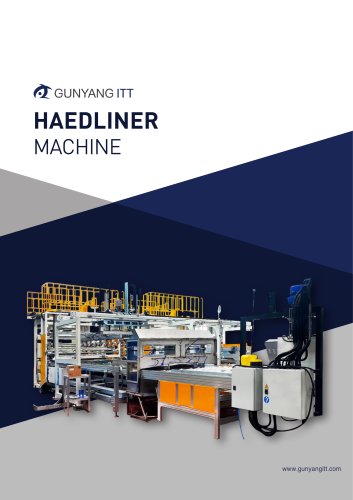

HAEDLINER MACHINE

Open the catalog to page 1

HISTORY of GUNYANG ITT Gunyang ITT was established in 1990 and has grown to be a leading company of automotive interior machine market. Based on our business philosophy, we’d like to create happiness for all employees and customers by providing our technology-intensive machines and long-term accumulated skills. Not only a machine manufacturer, but also a value creator, we provide complete solutions for automotive interior parts production. GUNYANG ITT CO.,LTD. #15, Mieumsandan5-ro 60 beon-gil, Gangseo-gu, Busan, Korea TEL +82-51-312-2400 FAX +82-51-314-2401 www.gunyang.co.kr TOTAL SYSTEM...

Open the catalog to page 2

GLOBAL SALES NETWORK Gunyang ITT exported machines for automotive interior parts to 41 clients in 21 countries such as China, Japan, Russia, India, Malaysia, Indonesia, United states, Mexico, Brazil, Argentina, France, Portugal, Spain, Slovakia, Turkey, United Kingdom, Germany, Czech republic, Poland, Iran, Republic Of South Africa and so on. - Korea head office : Busan - Japan support office : Nagoya - India support office : Pune - Europe support office : Berlin - China support office : Jinan, Guangzhou, Wuhan, Changsha, Chongqing, Zhengzhou, Shanghai, Tianjin - North America / Canada...

Open the catalog to page 3

SERIES of HEADLINER FORMING WET LINE GYHW Series (GYHW-01) Machine cycle time Material size Upper, lower layer Forming press Material loading Foam glue coating Multi nozzle Servomotor moving nozzle Multi nozzle Servomotor moving nozzle Multi nozzle Servomotor moving nozzle Multi nozzle Servomotor moving nozzle Halogen (group control) Ceramic (group control) Halogen (group control) Ceramic (group control) Skin feeding to covering press Covering press Part unloading Auto clamp And die lift Further discussion with client Auto clamp And die lift Further discussion with client Water spray...

Open the catalog to page 4

HEADLINER FORMING WET LINE GYHW-01 MACHINE PRODUCING AUTO PARTS FOR HEADLINER SPECIFICATIONS - Machine cycle time : 45 seconds - Skin size : Max : 1700 x 3000 Min : 1200 x 1400 - PU foam loading : Automatic (Option : Manual ) - Layer cutting and feeding : Automatic - Glue coating : Roll coater - Water spray : multi nozzle (Option: Servomotor moving nozzle) - Press : 200ton single press PU foam loading part Glue roll coating part Layer cutting and feeding part Water spray system Material layering & transfer Forming press part TOTAL SYSTEM SUPPLIER GUNYANG 05 TOTAL SYSTEM SUPPLIER GUNYANG ITT...

Open the catalog to page 5

HEADLINER FORMING WET LINE GYHW-02 MACHINE PRODUCING AUTO PARTS FOR HEADLINER SPECIFICATIONS - Machine cycle time : 45 seconds - Skin size : Max : 1700 x 3000 Min : 1300 x 1500 - PU foam loading : Manual (Option : Automatic ) - Layer cutting and feeding : Automatic - Glue coating : Roll coater - Water spray : multi nozzle (Option: Servomotor moving nozzle) - Press : 400-ton single press - Skin covering : While forming, skin covering simutaneous processing Water spray system Layered material feeding part Layer cutting and feeding part Forming press part TOTAL SYSTEM SUPPLIER GUNYANG ITT

Open the catalog to page 6

SERIES of HEADLINER FORMING DRY LINE GYHD Series (GYHD-01) Machine cycle time Material size Double press Forming press Single press Material loading Automatic Automatic Combined material loading Chain pin up/down +servo motor Material feeding Chain pin +servo motor Clamp up/down +servomotor Chain pin up/down +servo motor Chain pin up/down +servomotor Combined material feeding (skin+ substrate) Halogen (group control) Ceramic (group control) Ceramic (group control) Halogen (group control) Halogen (group control) Halogen (group control) Fire prevention device Heater box movement (maintenance)...

Open the catalog to page 7

HEADLINER FORMING DRY LINE GYHD-01 MACHINE PRODUCING AUTO PARTS FOR HEADLINER Substrate loading part SPECIFICATIONS - 1st heating cycle time : 70 seconds - 2nd heating cycle time : 45 seconds - Maximum skin size : 1800 x 3100 - Minimum skin size : 800 x 1500 - Material loading : Automatic - Material feeding : Substrate : Chain pin + Servo motor Skin : Clamp up/down + Servo motor - Heating : Halogen (Group control) - Forming press : 100-ton double press Substrate feeding Part Heating part Rail up down part Forming press part TOTAL SYSTEM SUPPLIER GUNYANG ITT

Open the catalog to page 8

HEADLINER FORMING DRY LINE GYHD-02 MACHINE PRODUCING AUTO PARTS FOR HEADLINER Substrate loading part SPECIFICATIONS - 1st heating cycle time : 70 seconds - 2nd heating cycle time : 45 seconds - Maximum skin size : 1750 x 2400 - Minimum skin size : 1300 x 2000 - Material loading : Automatic (Skin combined substrate loading ) - Material feeding : Automatic (Skin combined substrate loading ) - Substrate, Skin separated type : Option - Heating : Halogen (Group control) - Forming press : 100ton single press Substrate feeding Part Forming press part TOTAL SYSTEM SUPPLIER GUNYANG ITT

Open the catalog to page 9

EDGE FOLDING - HEADLINER GYHF-01 MACHINE SPECIFICATIONS Description GYHF Series (GYHF-01) Standard Machine cycle time Method Heating Skin and substrate simultaneous wrapping Skin wrapping Only Contact heating Edge wrapping area (Option) Loading , Unloading Front area, Rear area ,Sunroof area Manual TOTAL SYSTEM SUPPLIER GUNYANG ITT ITT TOTAL SYSTEM SUPPLIER GUNYANG 10

Open the catalog to page 10

HEADLINER STEEL BRACKET MACHINE GYHB-01 MACHINE SPECIFICATIONS Description GYHB Series (GYHB-01) Standard Machine cycle time 55s~ Nordson ( USA ) Phal bok system ( KOREA ) Based on customer required brand Nozzle unit Cartesian robot 5axis robot Hot melt Application Hot melt spray Loading TOTAL SYSTEM SUPPLIER GUNYANG ITT ITT TOTAL SYSTEM SUPPLIER GUNYANG 11

Open the catalog to page 11

GUNYANG ITT CO., LTD. #15, Mieumsandan5-ro 60 beon-gil, Gangseo-gu, Busan, Korea TEL +82-51-312-2400 FAX +82-51-314-2401 www.gunyang.co.kr

Open the catalog to page 12All GunYang ITT catalogs and technical brochures

-

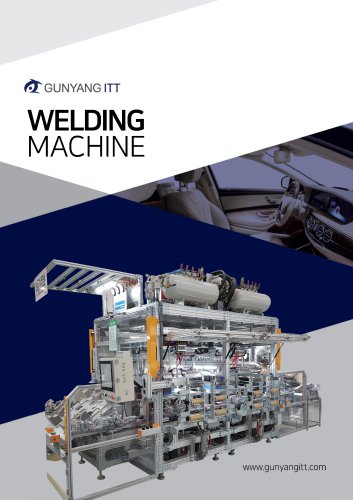

Welding Machine

13 Pages

-

Gunyang ITT profile 2020

24 Pages

-

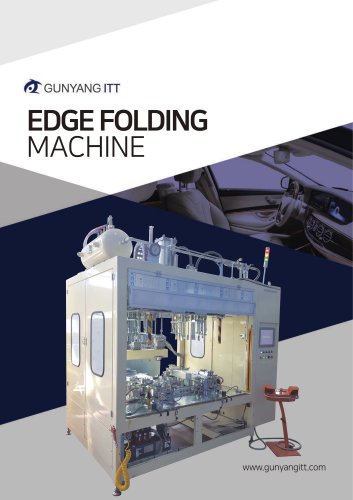

Edgefolding machine.s

8 Pages

-

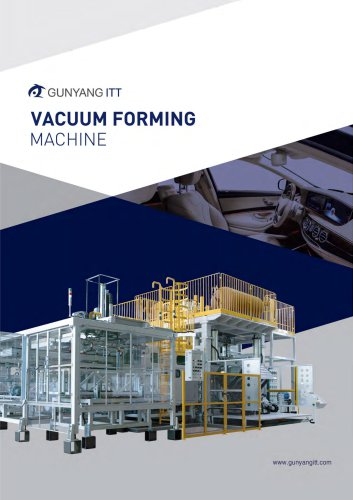

IMG Vacuum Forming Machine.s

12 Pages