Website:

Gullco International Limited

Website:

Gullco International Limited

Catalog excerpts

WELDING SYSTEM LINEAR OSCILLATOR MODELS: PK-500-LG-* PK-500-LH-* PK-500-LW-* (*INDICATES VOLTAGE REFERENCE) by: GULLCO INTERNATIONAL LIMITED - CANADA Website: www.gullco.com Phone: 905-953-4140 Fax: 905-953-4138 e-mail: sales@gullco.com GULLCO INTERNATIONAL INC. - U.S.A. Phone: 440-439-8333 Fax: 440-439-3634 e-mail: ussales@gullco.com GULLCO INTERNATIONAL [U.K.] LIMITED - EUROPE Phone: +44 1257-253579 Fax: +44 1257-254629 e-mail:uksales@gullco.com GULLCO INTERNATIONAL PTY LIMITED - AUSTRALIA Phone: 61 (0) 7 3348-5515 Fax: 61 (0) 7 3348-5510 e-mail: ausales@gullco.com GULLCO INTERNATIONAL INDIA PRIVATE LIMITED Phone: 91-20-65260382 Fax: 91-20-26836656 e-mail: India.lo@gullco.com GULLCO INTERNATIONAL SHANGHAI - LIMITED Phone: +8621-50460341 Fax: +8621-50463554 e-mail: c.zhang@gullco.com

Open the catalog to page 1

SAFETY INSTRUCTIONS Although the PIPE KAT® is manufactured for safe and dependable operation, it is impossible to anticipate those combinations of circumstances which could result in an accident. An operator of the PIPE KAT® is cautioned to always practice "Safety First" during each phase of operation, set-up and maintenance. Read and understand the operation manual before operating or performing service of this equipment. Become familiar with the machines operation, applications and limitations. Keep the operation manual in a clean and readily available location. This equipment is normally...

Open the catalog to page 6

SAFETY PRECAUTIONS The following cautionary/warning label is attached to each “PIPE KAT”® main control box The above label pictorially represents the following: “Warning:Read the manual before turning the unit on and before performing service. Also, positively disconnect the unit from all power supplies before servicing!” IMPORTANT READ THIS BEFORE OPERATING THE PIPE KAT® CARRIAGE WARNING! Always turn the main power off before connecting/disconnecting any cables to/from the PIPE KAT® carriage and main control box. Failure to comply may result in control damage. Do not cycle the power on and...

Open the catalog to page 7

THE PIPE KAT® WELDING SYSTEM COMPONENTS This manual covers the operation instructions of the following PIPE KAT® systems PK-500-LG-*, PK-500-LH-*, PK-500-LW-* (* indicates input voltage: “A”=42 VAC; “B” =115 VAC; “C”= 230 VAC). PIPE KAT® CARRIAGE WITH UMBILICAL PIPE KAT® PIPE BAND PIPE KAT® MAIN CONTROL WITH WELDING POWER SOURCE INTERFACE CABLE ASSEMBLY PIPE KAT® REMOTE PENDANT STORAGE / TRANS

Open the catalog to page 8

GENERAL DESCRIPTION The PIPE KAT® is an advanced portable travel carriage designed for orbital welding. It is an electrically powered track guided carriage that travels in forward and reverse directions at precisely controlled speeds. It consists of 24 VDC permanent magnet gear motor which engages the aluminum pipe band (track) through the self-aligning wheel system. Pipe bands are designed and manufactured to customer specific applications (pipe diameter). The band is typically constructed from extruded aluminum which insures a long life and durability in harsh conditions. The onboard wire...

Open the catalog to page 9

PIPE BAND The Pipe Band is constructed from extruded aluminum and uses adjustable stand-offs that serve as spacers to maintain the correct distance from the band to the pipe. The Pipe Band utilizes a quick adjustment latches that allows the operator to mount and remove the band easily. It is important that the Pipe Band is properly maintained and not subjected to any abuse as it serves an important role in the carriages drive system. The operator must play close attention to the condition of mating edge of the band that the PIPE KAT® carriage wheels run on. Care must be taken to ensure that...

Open the catalog to page 10

MOUNTING PIPE BAND (TRACK) ON THE PIPE 1. Loosen latch screws on both top swing latches and bottom fixed latches. Do not remove these screws. 2. Swing open the top pair of latches. 3. Separate or split the two bottom halves (fixed latches) of track away from each other. Important ! The bottom halves must be a minimum of 3/16” [5mm] apart from each other. This minimum distance will allow the track to safely open without causing interference between the two track halves. 4. Place track on pipe by sliding over the end, or by opening the track to fit over the pipe outside diameter. 5. Close...

Open the catalog to page 11

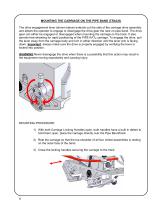

MOUNTING THE CARRIAGE ON THE PIPE BAND (TRACK) The drive engagement lever (shown below) extends out the side of the carriage drive assembly and allows the operator to engage or disengage the drive gear the rack on pipe band. The drive gear can either be engaged or disengaged when mounting the carriage on the track. It also permits free-wheeling for rapid positioning of the PIPE KAT® carriage. To engage the drive, pull the lever away from the carriage body and turn in either direction until the lever arm is facing down. Important: always make sure the drive is properly engaged by verifying...

Open the catalog to page 12

CARRIAGE UMBILICAL The umbilical assembly provides communication between the Main Control Box and the PIPE KAT® carriage, in addition to supplying cooling water, shielding gas and electrical welding power to the torch. The umbilical comprises of one control cable that provides power and communication to the carriage, two water hoses (supply and return), shielding gas hose and welding electrode cable. The umbilical is wrapped in a heat and abrasion resistant cover and uses a clamp to secure the umbilical assembly to the carriage (see pages 13 & 14 to see where the umbilical attaches to the...

Open the catalog to page 13

Connection to the PIPE KAT® Main Control includes: 1) Additional 15 ft welding power supply electrode cable 2) One (1) large electrical connector for communication supply to the carriage 3) One (1) male plug for the shielding gas supply to the torch 4) Additional 15 ft of water cooling hoses (supply & return) Connection to the PIPE KAT® carriage includes: 1) One (1) twist connect welding power supply cable connection 2) One (1) large electrical connector for carriage communication 3) One (1) quick-disconnect fitting for the torch shielding gas 4) Two (2) quick-disconnect fittings cooling...

Open the catalog to page 14All Gullco International Limited catalogs and technical brochures

-

KAT® 300 SERIES

2 Pages

-

KATBAK® Ceramic Weld Backing

3 Pages

-

GK-200

2 Pages

-

GOV 100 FH - 100

2 Pages

-

Pipe KAT- Rigid Band

4 Pages

-

KAT® Rigid Track Carriage

4 Pages

-

GK-192

1 Pages

-

rigid kat

1 Pages

-

Customized Welding Gantry

4 Pages

-

Vacuum Track Mounting System

4 Pages

-

Welding Positioner

4 Pages

-

Cutting Carriage - KAT II

2 Pages

-

Auto-Weld Carriage System

2 Pages

-

Automatic Overlay Welder

2 Pages