Catalog excerpts

The next generation shrink fit chucks from Guhring! • PERFECT CONCENTRICITY THANKS TO LENGTH SETTING SCREW WITH AXIAL FORCE DAMPING • 6 LOCATING BORES FOR HIGHEST BALANCE • MAXIMUM OPERATIONAL SAFETY WITH OPTICAL TEMPERATURE INDICATOR • OPTIMAL CORROSION PROTECTION DUE • STANDARD RANGE FOR HSK-A, ISO TAPER Thermo Secure Gold 3000 The high-end shrink fit chuck GUHRING - YOUR WORLD-WIDE PARTNER

Open the catalog to page 1

Thermo Secure Gold 3000 No fear of high temperatures Temperature indicator provides protection Up until now one couldn‘t tell a chuck‘s temperature. With the optical temperature indicator on Guhring Thermo Secure Gold 3000 chucks this source of danger is a thing of the past. A red ring signals: Attention, hot! Risk of burning! The chuck has a temperature above appr. 45° C. When the temperature drops below appr. 45° C, the ring turns blue. The chuck can now be held without danger. With a shrink fitted tool optimal clamping is now achieved. Coating protects surface A coated shrink fit chuck -...

Open the catalog to page 2

Thermo Secure Gold 3000 with temperature indicator for maximum operational safety 2. Red ring: The chuck is hot following shrink fitting for insertion. Risk of burning! 1. Shrink fitting: The chuck is heated up in the shrink fit system. Due to the radial expansion the tool can be inserted. 3. Putting on the cooling adapter: Through controlled cooling of the chuck the tool is securely clamped. 4. Blue ring: The cooling procedure is completed. The chuck now has a temperature below appr. 45° C. 5. Finished: The tool and holder can be removed from the shrink fit system without danger and...

Open the catalog to page 3

Thermo Secure Gold 3000 Length setting screw with axial force damping When shrink fitting, the heating and subsequent cooling of the chuck and tool not only causes the desired radial shrinking but also the unwanted axial shrinking. If the clamped tool is sitting on the setting screw, it can result in small inaccuracies in tool concentricity with conventional solutions. The new length setting screw with axial force damping from Guhring completely offsets this axial length difference through the integrated, flexible compensating element. The length setting screw with axial force damping can...

Open the catalog to page 4

Thermo Secure Gold 3000 6 locating bores for highest balance An imbalance produces a centrifugal force which is detrimental to the smooth running of the cutting tool. The consequence is a deterioration of the machined feature as well as a shorter tool life. Compensating to eliminate the imbalance completely is crucial for highly accurate machining. Thanks to the six balancing holes of the new Thermo Secure Gold 3000 an imbalance – in contrast to conventional holders with four balancing holes – can be compensated with pinpoint accuracy, easily and with total reliability. GÜHROJET available...

Open the catalog to page 5

HSK-A shrink fit chucks TSG 3000 Product information • coating for protection against oxidation, cleanliness and longevity • safety colour ring for maximum operator safety • with axial damping screw for optimal concentricity • MQL suitable • for tool shank tolerance h6 • to DIN 69882-8 • balancing quality G6.3 at 15,000 rev./min • designed with 6xM6 balancing screws for the highest accuracy Scope of delivery • incl. setting screw, Guhring no. 4941 • for conventional cooling order coolant delivery set, Guhring no. 4949, separately • for MQL application order as special tool holder with...

Open the catalog to page 6

ISO taper shrink fit chucks TSG 3000 Product information • coating for protection against oxidation, cleanliness and longevity • safety colour ring for maximum operator safety • with axial damping screw for optimal concentricity • for ISO40 to DIN 69871 form AD/B • balancing quality G6.3 / 15,000 rev./min • designed with 6xM6 balancing screws for the highest accuracy • form B supplied with threaded pins in bores. • for tool shank tolerance h6 Scope of delivery • incl. setting screw Guhring no. 4941for wet application • order draw bolt Guhring nos. 4925, 4926 separately • special dimensions...

Open the catalog to page 7

Countersinking/ de-burring Modular tooling systems Tool restoration service Special tooling solutions Tapping/thread milling/ fluteless tapping No liability can be accepted for printing errors or technical changes of any kind. Our Conditions of Sale and Terms of Payment apply. Available on request. The illustrations show optional equipment.

Open the catalog to page 8All GÜHRING catalogs and technical brochures

-

AEROSPACE

4 Pages

-

the best cast

36 Pages

-

DRILLING TOOLS

910 Pages

-

Grooving Systems

112 Pages

-

SuperLine 2016

148 Pages

-

GE 100 Floating holder

4 Pages

-

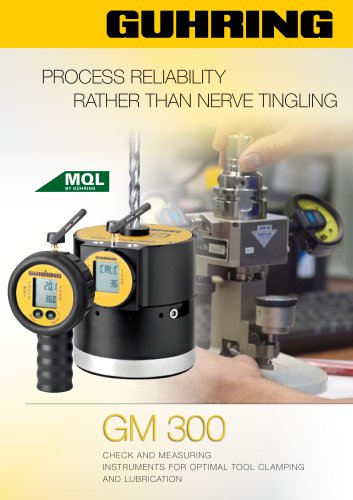

GM300_2015

228 Pages

-

GSS3001

5 Pages

-

Guhring Tool holders

4 Pages

-

GM 300 - MQL-Program

56 Pages

-

HMC 3000

6 Pages

-

GSS 2000

12 Pages

-

PCD and CBN tools

20 Pages

-

PCD-Highlights AMB 2014

2 Pages

-

Stainless steels

18 Pages

-

Tools for the mould and die industry

112 Pages

-

Turbochargers PR 1000 M

6 Pages

-

PCD/CBNTechnology

153 Pages

-

MILLING TOOLS - 2014

332 Pages

-

CONVENTIONAL gun drills

60 Pages