Website:

GÜHRING

Website:

GÜHRING

Catalog excerpts

TAPPING/THREAD MILLING/ FLUTELESS TAPPING Super Line SUPER PRICE SUPER QUALITY SUPER AVAILABILITY COUNTERSINKING MODULAR SYSTEMS SPECIAL TOOLING SOLUTIONS Guhring KG P.O. Box 100247 | 72423 Albstadt Herderstraße 50-54 | 72458 Albstadt Tel. + 49 74 31 17-0 Fax + 49 74 31 17-21279 info@guehring.de www.guehring.de No liability can be accepted for printing errors or technical changes of any kind. Our Conditions of Sale and Terms of Payment apply. Available on request.

Open the catalog to page 1

super price convincing price-performance-ratio exceptional quality immediate availability

Open the catalog to page 2

// Guhring’s SuperLine is a selected programme of high-tech tools for the machining operations drilling, milling, threading and reaming. The carbide or selected high speed steel precision tools are optimised with state-of-the-art coatings. Thanks to innovative manufacturing processes, world-wide uniform quality standards and large manufacturing quantities, the SuperLine range is unique regarding economic efficiency, quality, delivery time and service.

Open the catalog to page 3

// Immediate availability The immediate availability of SuperLine tools is a pillar of the programme. For you as the customer it means order today and apply tomorrow. For us as manufacturer it means we can ensure an intelligent solution regarding raw materials, manufacture and delivery. SL tools are available ex-stock. Put us to the test.

Open the catalog to page 4

PRODUCTION CENTRES SALES COMPANIES SERVICE CENTRES // Service near to the customer Guhring provides a re-grind and re-coating service to ensure a long tool life of SuperLine tools. The high-tech tools are refurbished with original coatings and geometries and subsequently regain their performance. In addition, Guhring’s own collection and delivery service ensures on schedule logistics for tool refurbishment. Thanks to a global service network including re-grind centres as well as world-wide uniform manufacturing facilities we guarantee maximum quality standards close to the customer. Further...

Open the catalog to page 5

SL twist drills Table of contents Programme Gühring Navigator from page 8 from page 15 from page 72 SL thread cutting tools Table of contents Programme Gühring Navigator from page 10 from page 77 from page 94 SL milling cutters Table of contents Programme Gühring Navigator from page 12 from page 99 from page 124 SL reamers Table of contents Programme Gühring Navigator from page 14 from page 129 from page 132

Open the catalog to page 7

Tool illustration Drilling Shank depth form Type Standard Tool Sur-material face Ratio drills with oil feed £ Ratio drills without oil feed Stub drills

Open the catalog to page 8

Tool illustration Drilling Shank depth form Type Standard Tool Sur-material face Article Cutting d1/mm Anple data Page Stub drills Jobber drills Long series twist drills Solid carbide micro-precision drills without coolant ducts WN

Open the catalog to page 9

Tool illustration Toler-Standard Type Form ance on 0 Tool Sur-material face Machine taps for ISO metric threads C 6HX HSS-E C Fluteless machine taps for ISO metric threads

Open the catalog to page 10

Tool illustration Tool Sur-material face Toler-Standard Type Form ance on 0 Article Cutting d1/mm An-le data Page Thread milling cutters without chamfer for ISO metric threads TM SP

Open the catalog to page 11

Shank form Tool Sur-material face Standard Ratio end mills RF 100 U m 4 m Mini slot drills (3-fluted) Roughing end mills GS 100 U (fine teeth) Hard roughing end mills GS 100 H (fine teeth)

Open the catalog to page 12

ArticlpCutting di/mm data Page Mini slot drills (3-fluted) Ball nose slot drills (2-fluted) Ball nose end mills (4-fluted) Chamfering milling cutters Ratio end mill sets RF 100 U

Open the catalog to page 13

Tool illustration Drilling Standard Form depth Cutting Tool direction material Cutting data Page page Reaming recommendations for carbide NC reamers Interrupted holes Spiral reamers are preferred for the application in interrupted holes because the cutting edge geometry, in comparison to straight-fluted tools, possesses a lesser tendency of grabbing on the oblique hole. Through hole or blind hole Straight-fluted reamers are generally applied in blind holes as they, due to their cutting edge geometry, evacuate the chips from the hole against the direction of the feed. Blind holes can be...

Open the catalog to page 14

TWIST DRILLS

Open the catalog to page 15

SL TWIST DRILLS Ratio drills with oil feed RT 100 DIN 6537 K U Tool material Discount group web thinning ≥ Ø 3.000 • facet point grinding • main cutting edge form straight • optimised cutting geometry structural and case hardened steels • free-cutting steels, heattreatable steels • steels (alloyed/unalloyed) up to 1200 N/mm² • cast materials • bronze, brass • high-alloyed AlSi-alloys Cutting data page 72

Open the catalog to page 16

Article no. Discount group

Open the catalog to page 17

Discount group

Open the catalog to page 18

Tool material Solid carbide Surface Shank form Discount group web thinning ≥ Ø 3.000 • facet point grinding • main cutting edge form straight • optimised cutting geometry Ratio drills with oil feed stainless/acid-/heat-resistant steels • Titanium and Titanium alloys • Inconel, Hastelloy, Monel Cutting data page 72

Open the catalog to page 19

Discount group

Open the catalog to page 20

Article no. Discount group

Open the catalog to page 21

SL TWIST DRILLS Ratio drills with oil feed RT 100 DIN 6537 L U Tool material Surface Shank form Solid carbide web thinning ≥ Ø 3.000 • facet point grinding • main cutting edge form straight • optimised cutting geometry structural and case hardened steels • free-cutting steels, heattreatable steels • steels (alloyed/unalloyed) up to 1200 N/mm² • cast materials • bronze, brass • high-alloyed AlSi-alloys Cutting data page 72 Discount group

Open the catalog to page 22

Article no. Discount group

Open the catalog to page 23

Discount group

Open the catalog to page 24

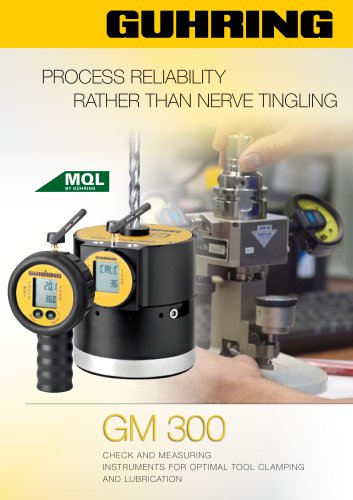

Article no. Discount group GM 300 toolholders and clamping devices for every application Overview and selection guide can be found on page

Open the catalog to page 25

SL TWIST DRILLS Ratio drills with oil feed RT 100 DIN 6537 L VA Tool material Solid carbide Surface Shank form Discount group web thinning ≥ Ø 3.000 • facet point grinding • main cutting edge form straight • optimised cutting geometry stainless/acid-/heat-resistant steels • Titanium and Titanium alloys • Inconel, Hastelloy, Monel Cutting data page 72

Open the catalog to page 26All GÜHRING catalogs and technical brochures

-

AEROSPACE

4 Pages

-

the best cast

36 Pages

-

DRILLING TOOLS

910 Pages

-

Grooving Systems

112 Pages

-

GE 100 Floating holder

4 Pages

-

GM300_2015

228 Pages

-

GSS3001

5 Pages

-

Guhring Tool holders

4 Pages

-

GM 300 - MQL-Program

56 Pages

-

HMC 3000

6 Pages

-

TSG 3000

8 Pages

-

GSS 2000

12 Pages

-

PCD and CBN tools

20 Pages

-

PCD-Highlights AMB 2014

2 Pages

-

Stainless steels

18 Pages

-

Tools for the mould and die industry

112 Pages

-

Turbochargers PR 1000 M

6 Pages

-

PCD/CBNTechnology

153 Pages

-

MILLING TOOLS - 2014

332 Pages

-

CONVENTIONAL gun drills

60 Pages